Semi-automatic cuff type bagging machine

A coating machine, semi-automatic technology, applied in the direction of external support, packaging bottles, transportation packaging, etc., can solve the problems of reducing equipment operation monitoring, packaging bottles scattered on the ground, and cannot be found in time, so as to achieve convenient operation, save packaging costs, The effect of guaranteeing the quality of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

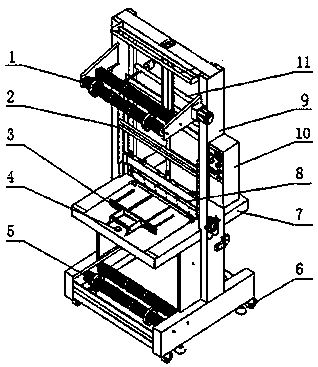

[0010] like figure 1 As shown, a semi-automatic cuff-type film covering machine is mainly composed of an upper film discharging device 1, a film guiding roller 2, a front supporting device 3, a lower film discharging device 4, a supporting part 5, a rear supporting device 6, and a sealing and cutting device 7 , a control system 8, a main frame 9, an upper constant force device 10 and an upper film-hanging device 11, the main frame 9 is arranged above the rear supporting device 6, and a supporting part 5 is arranged in the rear supporting device 6, and the rear The main frame 9 above the supporting device 6 is provided with a lower film discharge device 4, the lower film discharge device 4 is provided with a front support device 3, and the main frame 9 above the lower film discharge device 4 is provided with a control system 8, the control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com