Goods shelf type intelligent storage method and intelligent storage device

A smart warehousing and intelligent technology, applied in storage devices, transportation and packaging, etc., can solve the problems of large space occupation, low work efficiency, and high cost, and achieve the effects of high work efficiency, easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

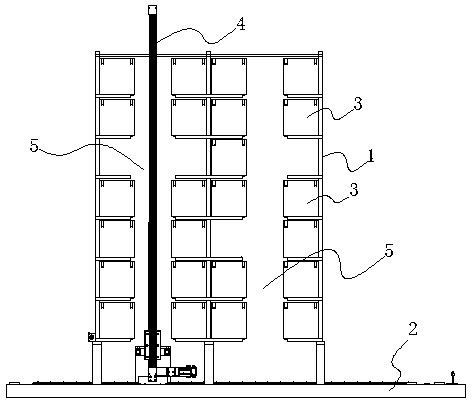

[0042] Embodiment 1: A shelf-type intelligent storage method, which is to set a plurality of shelves arranged in a straight line and an intelligent lifting mechanism that can move back and forth along the multiple shelves, and store through the cooperation of the intelligent lifting mechanism and the multiple shelves. When accessing goods, it can be stored or retrieved from the top of multiple shelves through intelligent lifting, and can also be stored or retrieved from the bottom of multiple shelves.

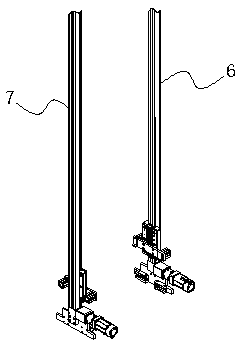

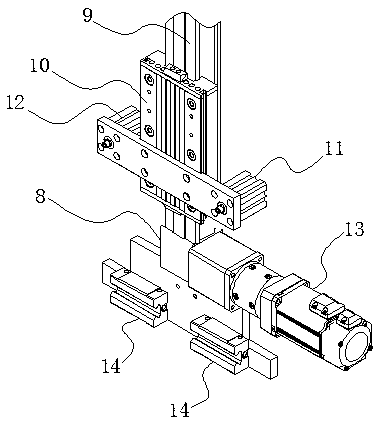

[0043] like figure 1 As shown, a bottom conveying line 2 is set at the bottom of a plurality of shelves 1 to form a bottom conveying passage, so that the storage box 3 is stored above the bottom conveying passage; the multiple storages conveyed by the bottom conveying passage through an intelligent lifting mechanism 4 The boxes 3 are stacked on multiple shelves 1 in sequence for storage or the storage boxes 3 on the multiple shelves 1 are taken out by an intelligent lifting mec...

Embodiment 2

[0063] Embodiment 2: as Figure 5 and Figure 6As shown, compared with Embodiment 1, the difference is that a top pick-up mechanism 15 is also arranged between the top of the main frame 8 of the lifting mechanism one and the top of the main frame 8 of the lifting mechanism two, and the top pick-up mechanism 15 comprises a support frame body 151 arranged between the main frame top of the lifting mechanism one and the main frame 8 top of the lifting mechanism two and a guide rod 152 arranged on the support frame body 151; a nut seat is slidably connected on the guide rod 152 153, the support frame body 151 is also provided with a screw motor 155 with a driving screw 154, the driving screw 154 of the screw motor passes through the nut seat 153 and is matched and connected by the driving screw 154 and the nut seat 153, Thereby drive nut seat 153 along guide rod 152 on horizontal direction, move back and forth; Also be provided with vertical cylinder 16 on nut seat 153, also be pr...

Embodiment 3

[0069] Embodiment 3: as Figure 7 and Figure 8 As shown, compared with Embodiment 2, the difference is that: a lifting and picking box 18 is also arranged on the outermost shelf 1, and the top picking mechanism 15 is controlled in the S3 step in Embodiment 1 to put the goods down and send them out. The time is to control the top picking mechanism 15 to place the goods in the lifting and picking box 18, and then control the lifting and picking the box 18 to move down to drive the goods to move to the picking area, and the goods are sent out.

[0070] The lifting and picking box 18 includes a picking synchronous belt mechanism 182 arranged on the lifting and picking pillar 181, a lifting seat 183 arranged on the picking synchronous belt mechanism 182, and a picking box arranged on the lifting seat 183 184, under the drive of the timing belt mechanism 182 for picking up goods, the lifting seat body 183 can drive the picking up box 184 to move up and down together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com