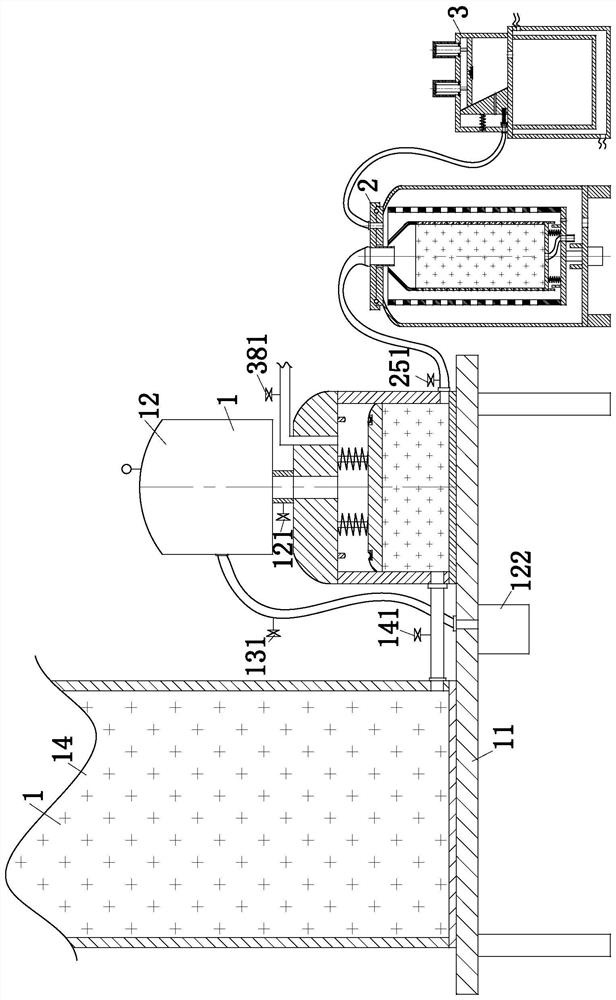

Alcohol distillation system for liquor production

A distillation system and alcohol technology, applied in the field of alcohol distillation system for liquor production, can solve the problems of use restriction, waste of resources, incomplete alcohol collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

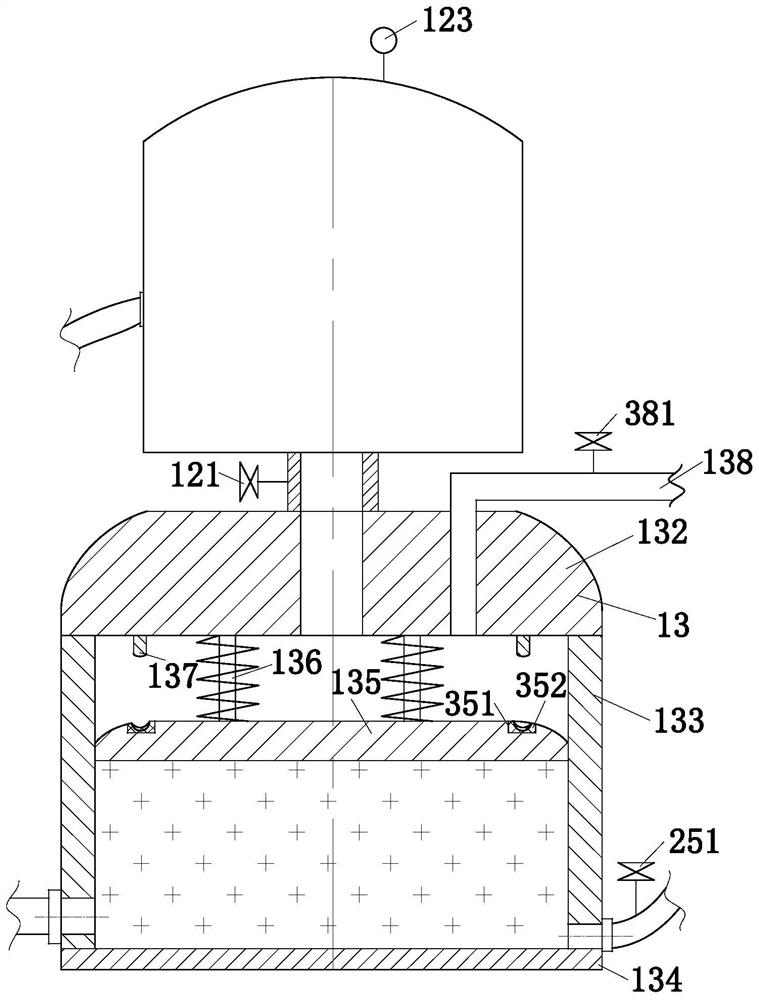

[0028] As an embodiment of the present invention, the upper surface of the No. 1 rubber pad 352 is provided with a circular groove with a semicircular section; the lower surface of the No. 1 ring block 137 is an arc-shaped surface; the circular groove passes through Cooperating with the arc surface on the lower surface of the No. 1 ring block 137 can increase the stress area between the No. 1 ring block 137 and the No. 1 rubber pad 352, and the arc surface of the No. 1 ring block 137 has no sharp corners so as not to No. 1 rubber pad 352 causes the phenomenon of puncture.

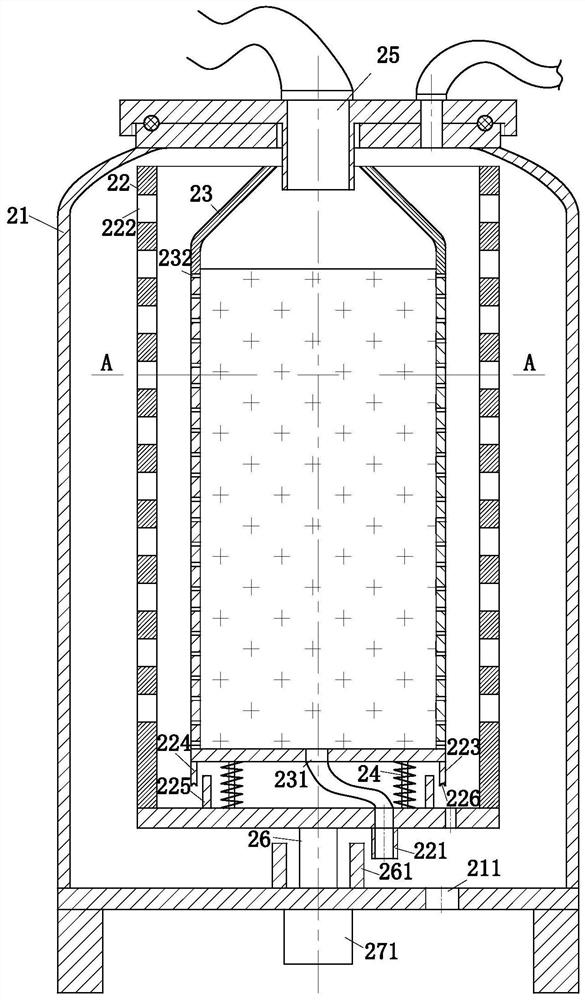

[0029]As an embodiment of the present invention, the extraction module 2 includes an installation cylinder 21, a first horn 22, a second horn 23, a second sliding telescopic rod 24, a feed pipe 25 and a rotating shaft 26. The inner layer of the installation cylinder 21 A horn 22 is provided; the first horn 22 is connected to the motor 271 through a rotating shaft 26; the second horn 23 is installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com