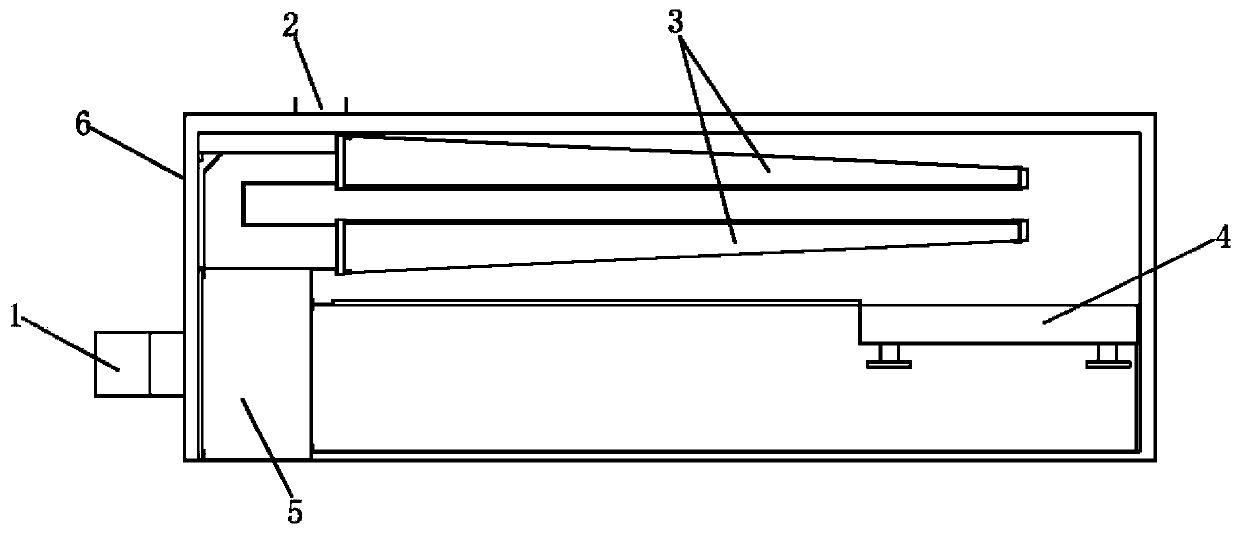

Oven structure of a stenter heat setting machine

A technology of heat setting machine and oven, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric elongation, etc. It can solve the problems of poor fluid operation and uneven temperature distribution of the setting machine, and solve the problem of poor air exhaust , optimize the local flow field and reduce the effect of vortex intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

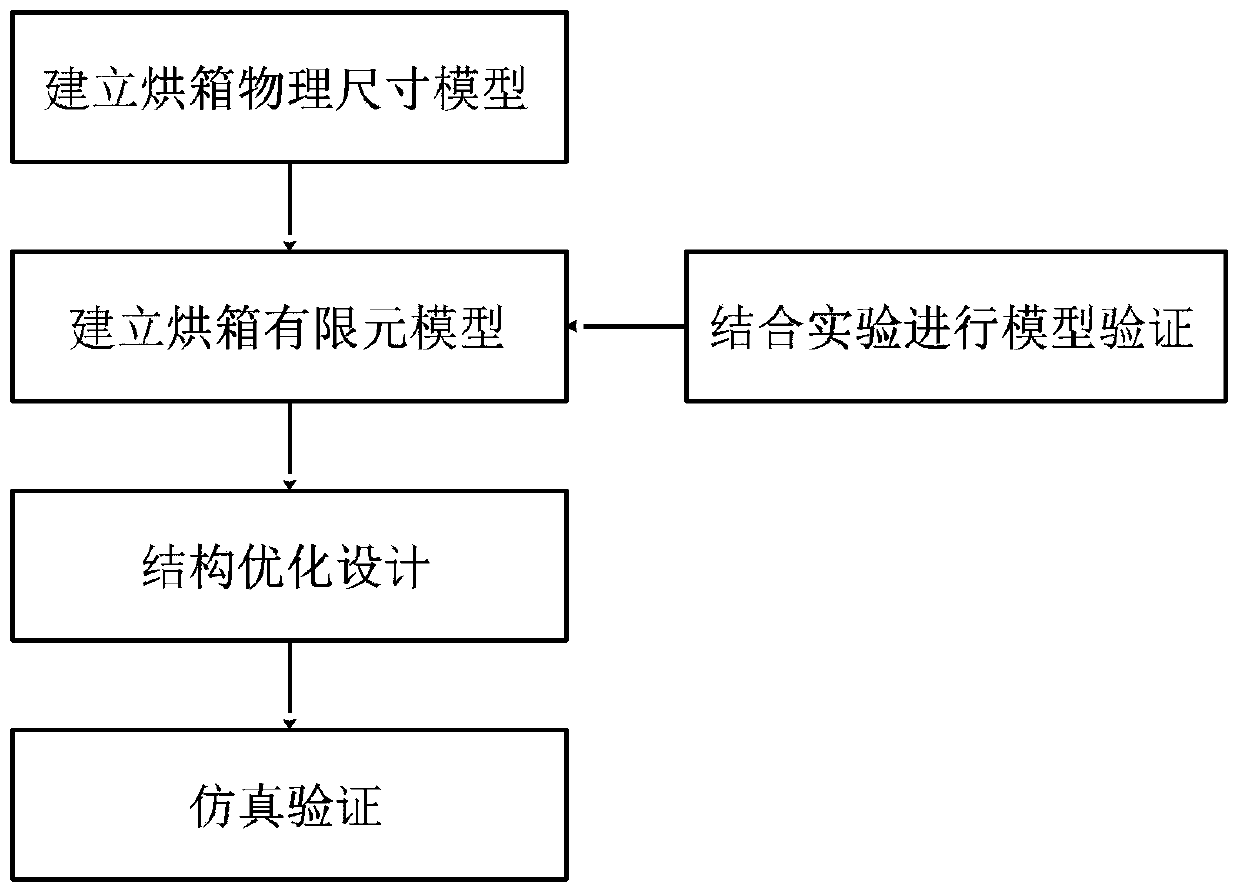

[0030] By analyzing the structure of the existing sizing machine oven, using CFD software to simulate the problem of poor fluid flow and uneven distribution of the internal temperature field during the operation of the oven, and on this basis, a new type of mechanism is proposed. This problem can be solved by improving the internal flow state and eliminating the unstable flow field structure. The overall flow chart is as figure 2 as shown,

[0031] One: Build a physical size model

[0032] Based on the traditional stenter heat setting machine, a 1:1 physical size model is established. Based on the 3D model of equal size, the simulation of the internal flow field and the verification after optimization are done.

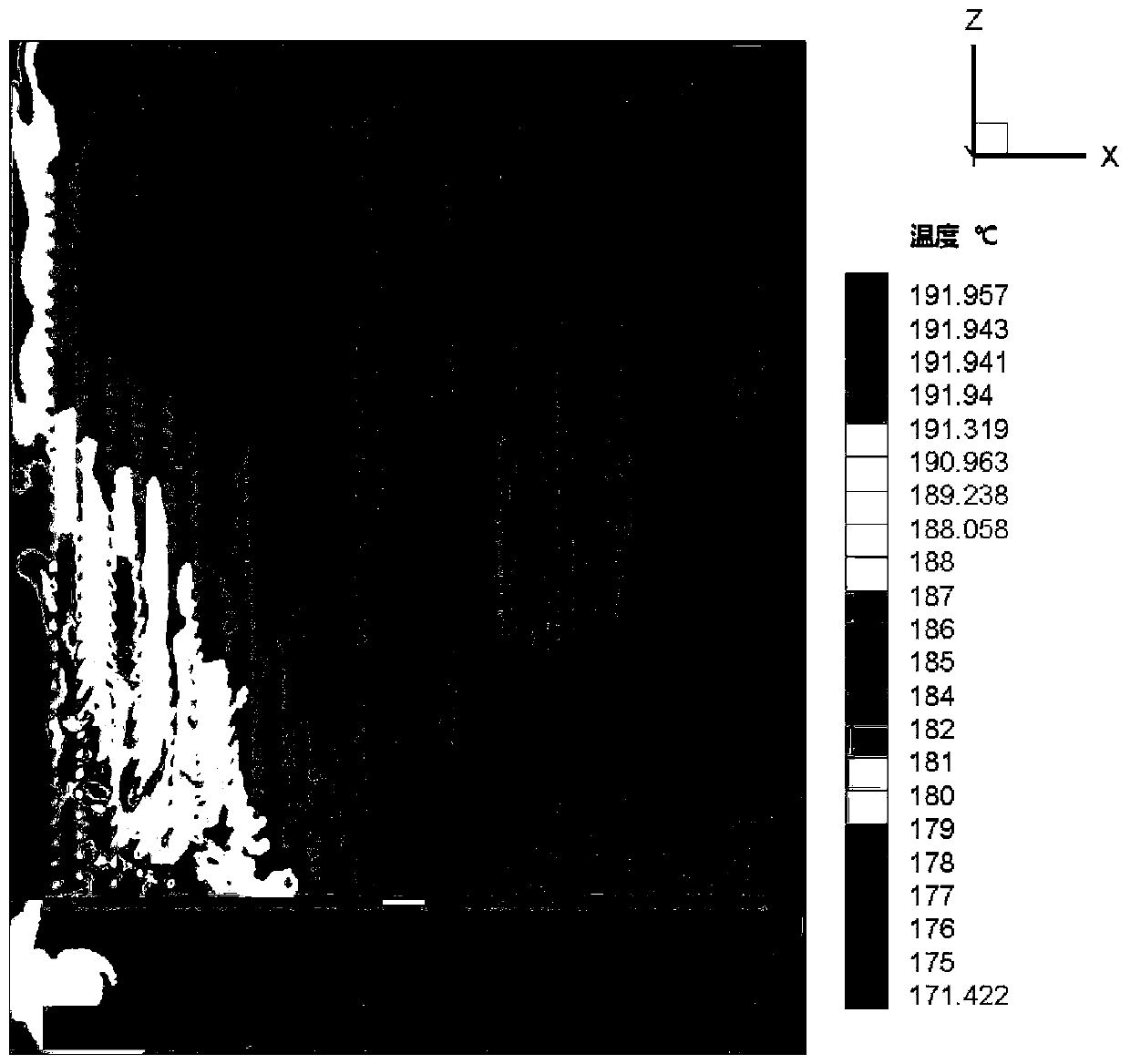

[0033] Two: Carry out finite element-based fluid simulation

[0034] In order to carry out CFD simulation, the present invention carries out s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com