Silent range hood

A technology for range hoods and range hoods, which can be used in the removal of range hoods, household heating, lighting and heating equipment, etc., and can solve problems such as high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

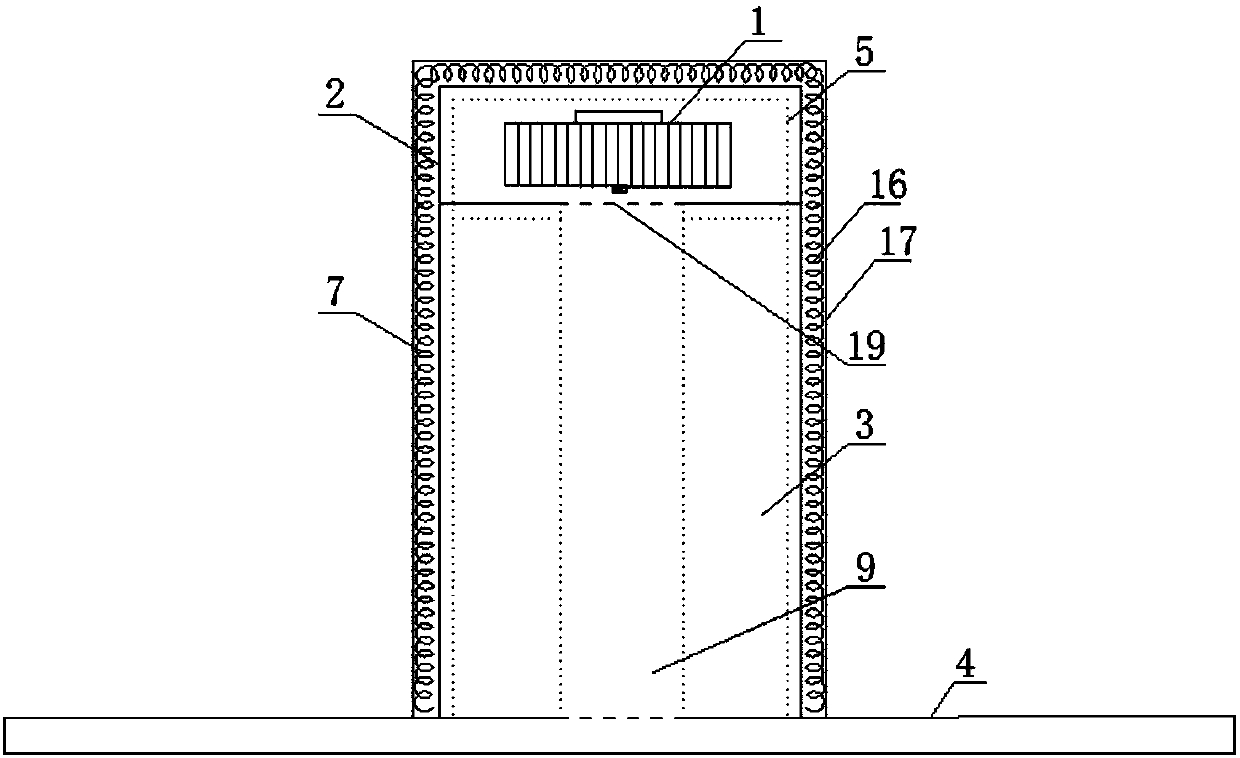

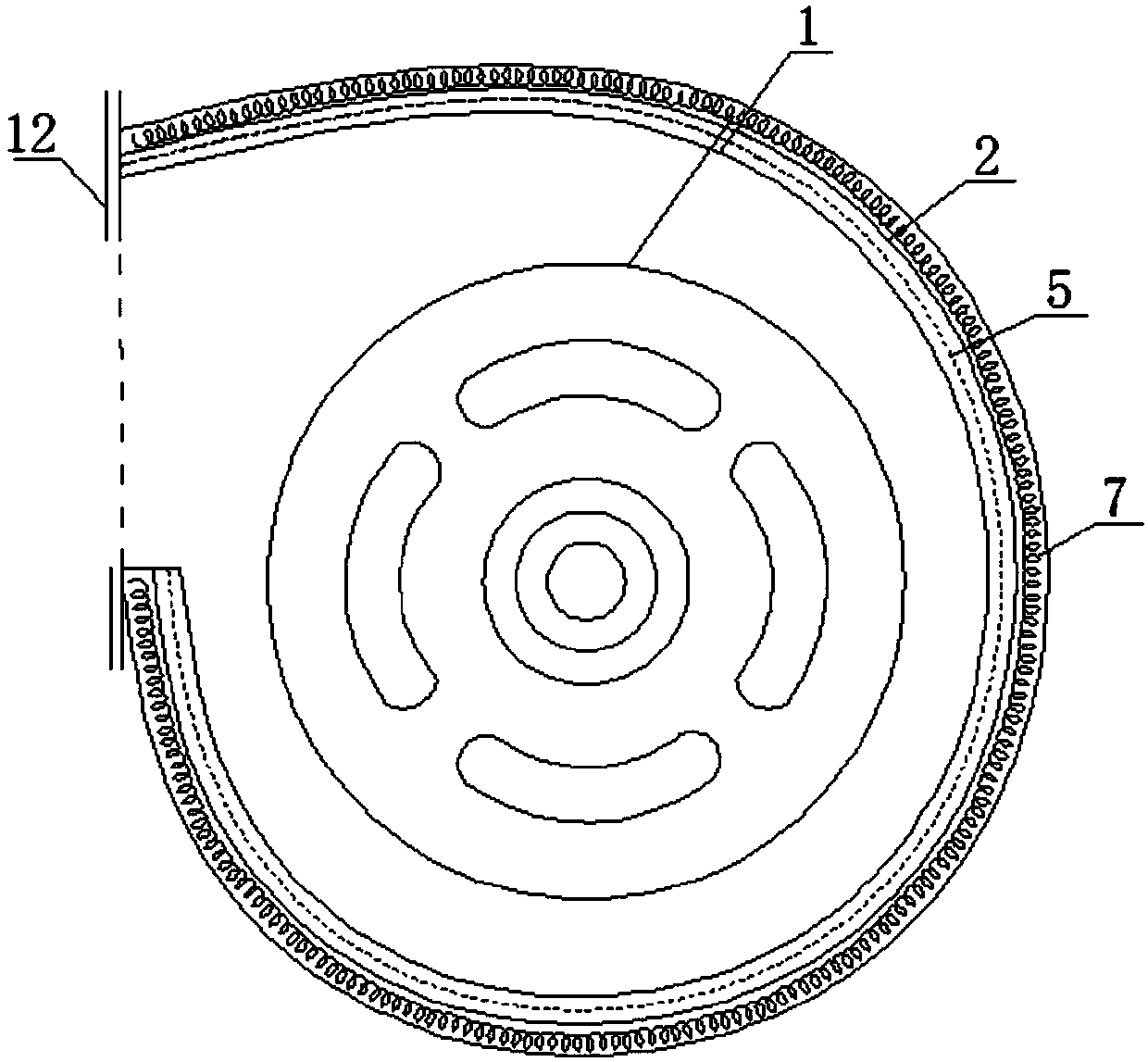

[0038] Such as figure 1 , figure 2 As shown, in this embodiment, a silent kitchen range hood is provided, which includes an integrally configured fan 1, a fan silencer box 2, a muffler 3 and a range hood 4, and the fan 1 is arranged in the fan silencer box 2. The fan silencer box 2 is horizontally arranged on the top of the muffler 3 , the oil suction hood 4 is arranged on the bottom of the muffler 3 , and the center of the muffler 3 is an oil fume suction chamber 9 . Both the fan silencer box 2 and the shell of the muffler 3 are equipped with a sound-absorbing structure 7 . It should be noted that the above fan 1 is a centrifugal fan or an axial flow fan. In this implementation, the fan 1 is taken as an example for illustration.

[0039] During operation, the impeller of the fan 1 runs horizontally in the fan silencer box 2, and the fan silencer box 2 forms a negative pressure, and the oil fume passes through the oil suction hood 4, passes through the oil fume suction cham...

Embodiment approach 2

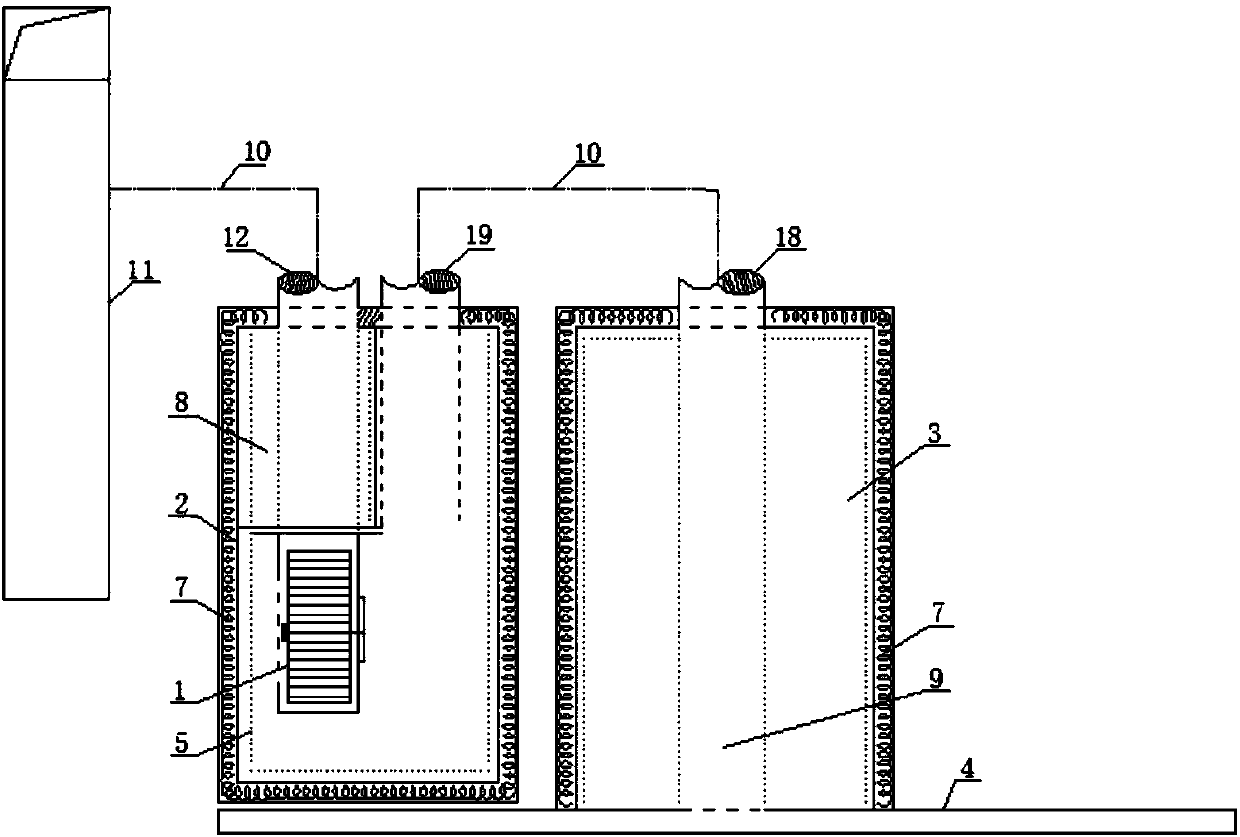

[0049] refer to image 3 , On the basis of Embodiment 1, the fan 1 and the fan silencer box 2 are set independently to enhance the noise reduction level of the fan silencer box 2. figure 1 Due to the limitation of the size of the traditional decorative board, the fan silencer box 2 cannot be made too large, so the noise reduction effect of the fan silencer box 2 is limited. In order to further reduce the high-frequency noise and low-frequency vibration noise generated by the fan 1, the fan silencer box 2 is independent Configurations, from the factory two-piece set product shipped.

[0050] image 3 Among them, the volume of the suction box in the fan silencer box 2 casing is increased, which is equivalent to an anti-type muffler, which greatly reduces the noise of the fan 1 and is passed to the muffler 3 by the suction duct through the muffler air duct 10, which is beneficial to reducing the overall noise. In the space between the air outlet of the fan 1 and the air outlet ...

Embodiment approach 3

[0054] refer to Figure 4 , on the basis of Embodiment 2, a second muffler 6 is configured, and the air duct interface 21 of the second muffler 6 is connected to the air inlet 19 of the fan muffler box 2 through the muffler air duct 10, and the air duct interface of the second muffler 6 22 is connected with oil fume outlet duct 18 through air duct 20. Figure 4 Since the second muffler 6 and the muffler 3 are added to muffle the noise from the fan muffler box 2, the noise reduction effect is further improved, forming an ultra-quiet range hood. In order to increase the wind pressure and air volume of the fan, it can provide super large production capacity. Extractor and extractor hoods create space to ship from the factory in a three-piece set.

[0055] The air duct interfaces 21, 22 of the second muffler 6 are all drawn from the top, mainly considering that the air ducts are convenient to be arranged in the suspended ceiling, otherwise the air duct interfaces all lead out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com