Glass powder tumbling device and mixing processing equipment using the device

A glass powder and tumbling technology, used in grain processing and other directions, can solve the problems of easy falling, affecting service life, wear of tanks and metal sheets, etc., and achieve the effect of improving the working environment, increasing service life, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

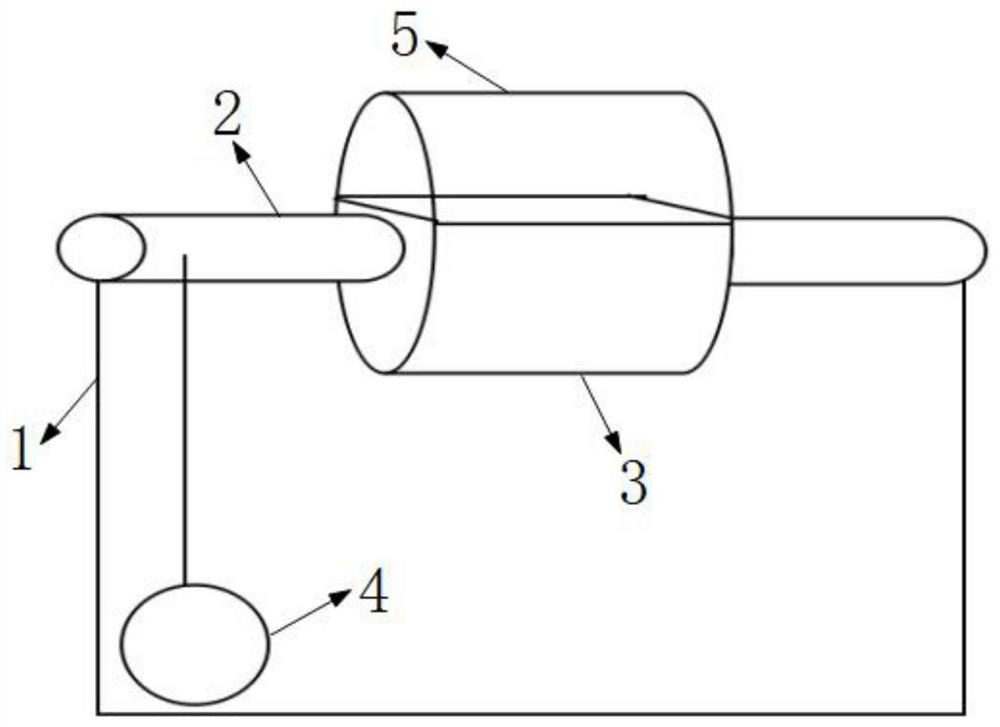

[0031] (1) The motor device drives the driving wheel, and the driving wheel drives the driven wheel on the metal rod to rotate through the belt or chain.

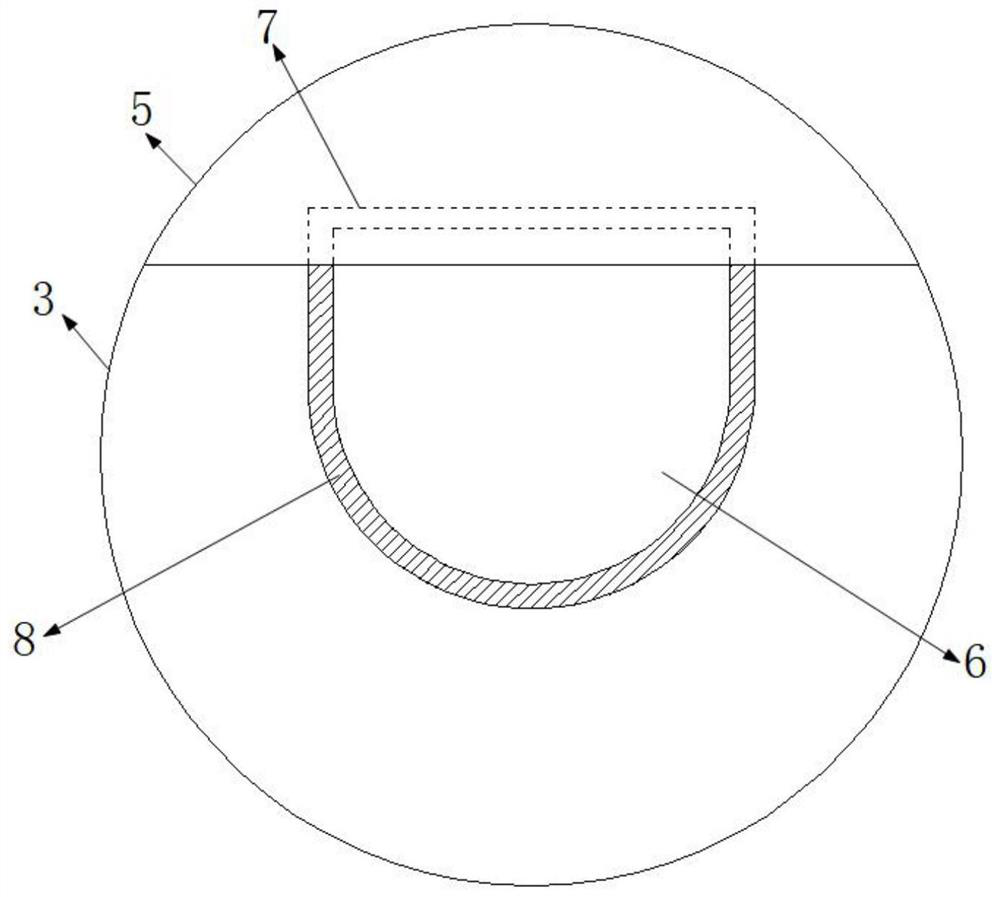

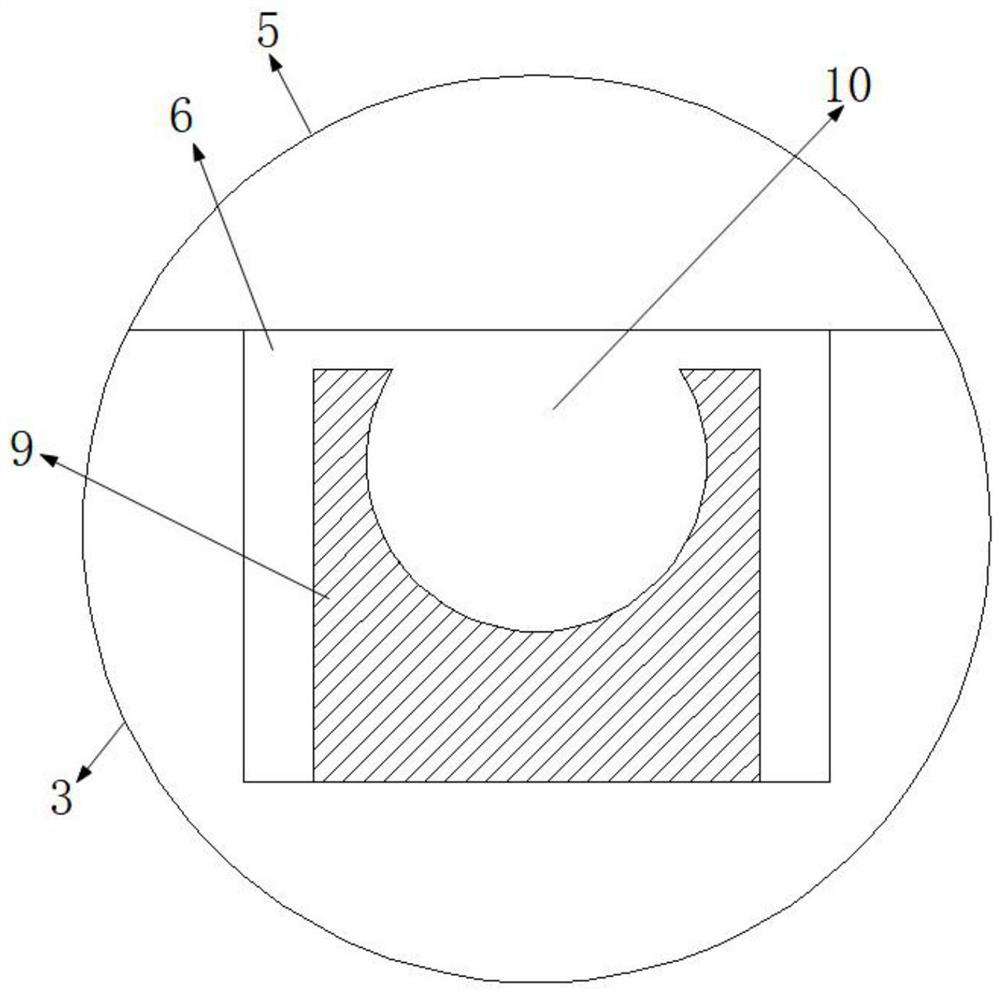

[0032] (2) There is a large fixed ferrule structure 3 in the middle of the metal rod, and there is also a movable ferrule structure. The movable ferrule structure 5 and the fixed ferrule structure 3 cooperate with each other. The fixed ferrule structure 3 can be a circle with a superior arc in cross section. shaped structure, the movable ferrule structure 5 can be a circular structure with a minor arc in section.

[0033] (3) During use, the configured ceramic jar is put into the circular fixed ferrule structure 3, and the movable ferrule structure 5 is covered on the top, and fastened with buckles on both sides.

[0034] (iv) Start the motor device, the ceramic pot can rotate silently, and the inner glass powder can realize the rolling action.

Embodiment 2

[0036] In the structural configuration of the present invention:

[0037] The external shape of the ceramic tank is cylinder, cuboid, sphere or any polyhedron shape. Cooperating with the outer shape of the ceramic pot, the groove body shape of the ferrule inner groove 6 in the fixed ferrule structure 3 is also cylindrical, cuboid, sphere or any polyhedron shape.

[0038] The movable ferrule structure 5 is provided with a limit reinforcement structure 7, and the limit reinforcement structure 7 matches the position of the opening side of the ferrule inner groove 6 in the fixed ferrule structure 3.

[0039] The surface layer of the ferrule inner groove 6 and the surface layer of the limit reinforcement structure 7 are all provided with a layer of anti-skid pad 8, the anti-skid pad 8 can be a rubber pad, and the rubber pad and the surface layer of the ferrule inner groove 6 and the surface layer of the limit reinforcement structure 7 are bonded agent bonding.

[0040] The ferrul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com