Two-way tensile loading device

A loading device, biaxial stretching technology, applied in measuring devices, using stable tension/pressure testing materials strength, instruments, etc., can solve the problem of high test cost, lack of bidirectional loading test guidance documents, annular device clamping Design difficulties and other problems, to achieve the effect of low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof. The accompanying drawings show, by way of example, specific embodiments in which the invention can be practiced. The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention.

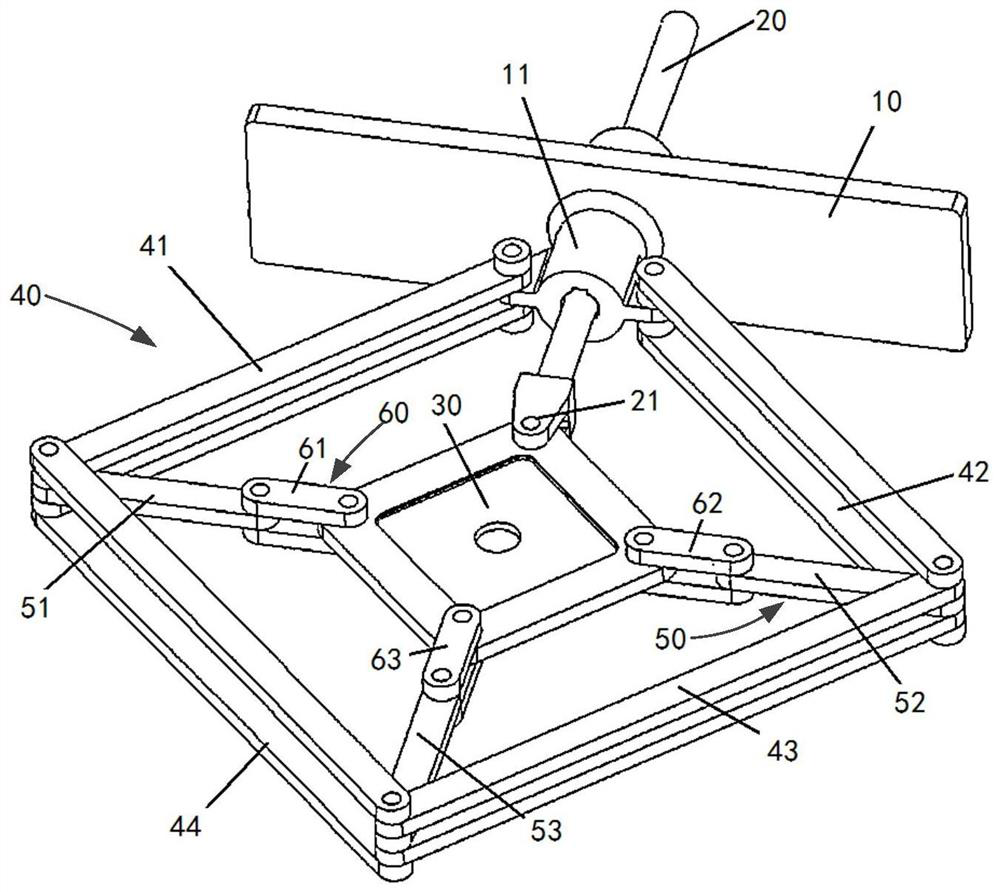

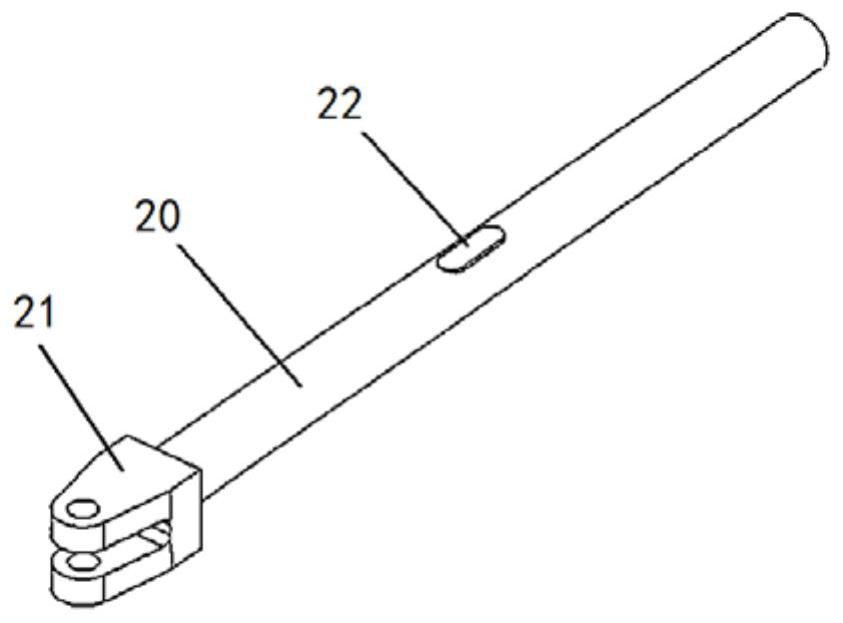

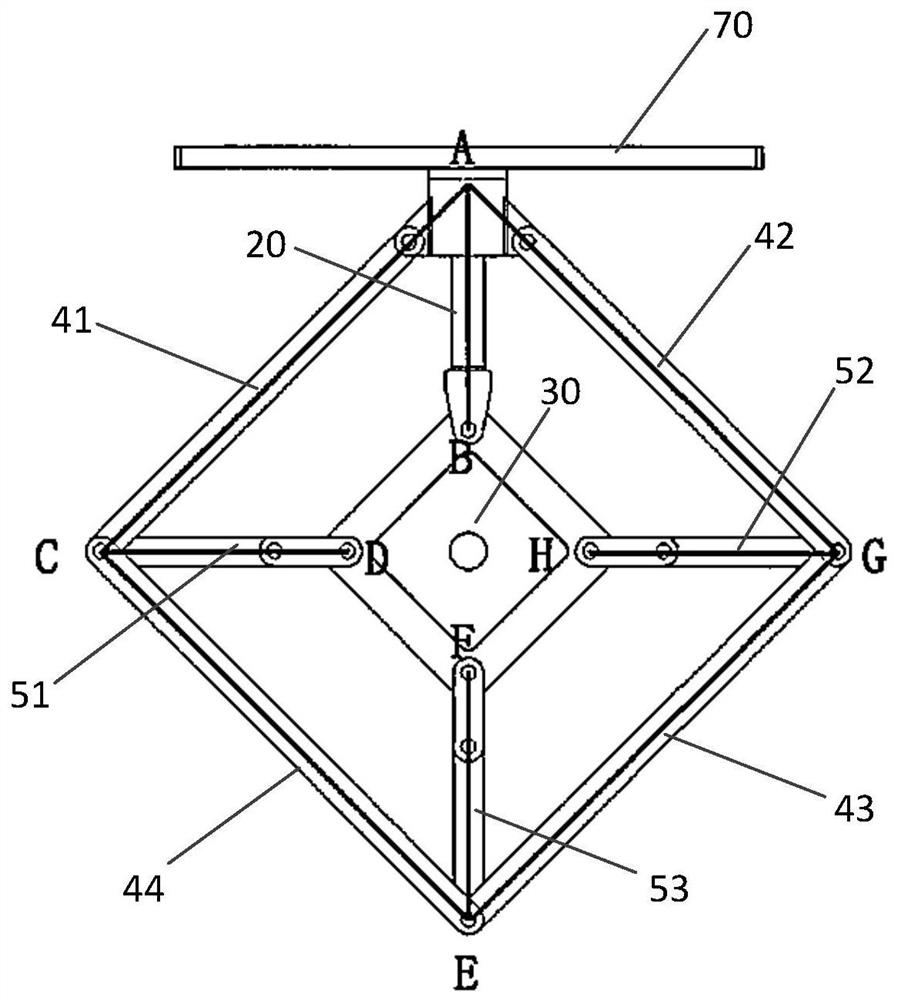

[0024] Such as Figure 1 to Figure 2 shown in . The bidirectional tension loading device according to the present invention includes a fixed base 10, a loading rod 20 and a link mechanism. The loading rod 20 vertically passes through the fixed base 10 and can move vertically relative to the fixed base 10 . The upper end of the loading rod 20 is connected to the mechanical testing machine, and the lower end is provided with an ear piece 21 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com