A dual-degree-of-freedom platform drive controller for an embedded ultrasonic motor

A technology for driving controllers and ultrasonic motors, which is applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. The platform drive control system is bulky and the efficiency of the control algorithm is low. It achieves the effect of continuous real-time frequency signal adjustment, low cost, and high-performance speed control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

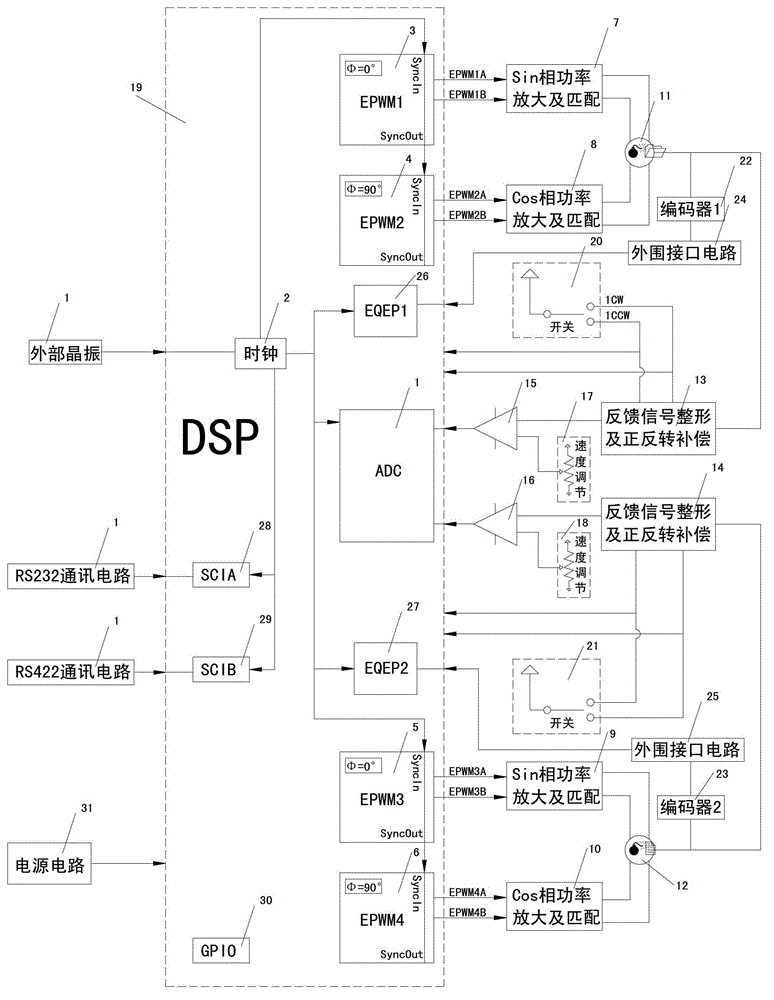

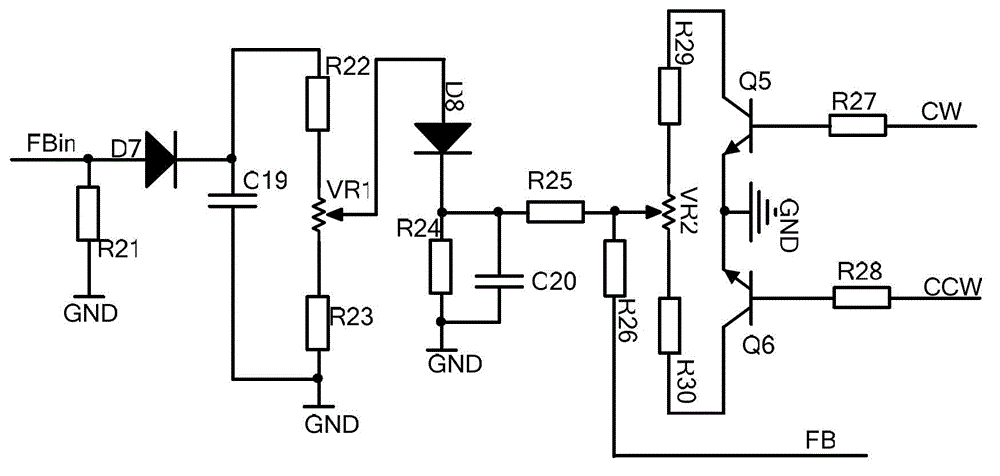

[0029] Such as figure 1 As shown, the embedded ultrasonic motor dual-degree-of-freedom platform drive controller of this embodiment includes an external crystal oscillator input unit 1, an embedded microprocessor 19, and a power amplification and matching unit. The clock signal sent by the external crystal oscillator input unit 1 passes through The EPWM clock unit 2 in the embedded microprocessor 19 is distributed to the first EPWM module 3, the second EPWM module 4, the third EPWM module 5 and the fourth EPWM module 6;

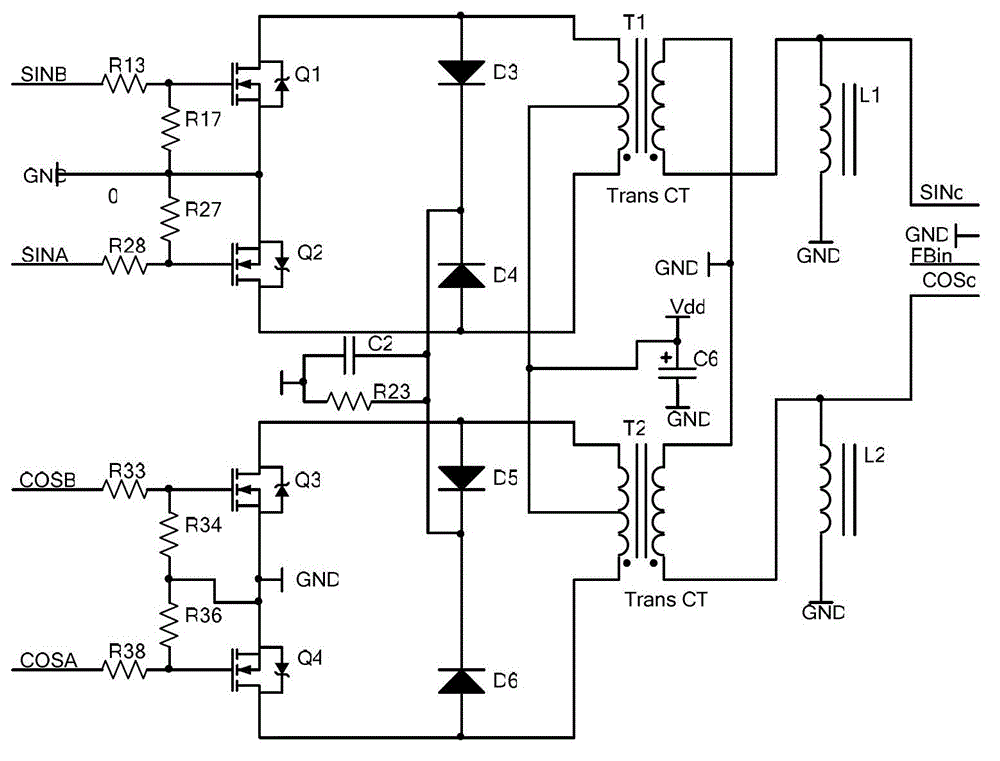

[0030] The output signal of the first EPWM module 3 is processed by the first power amplification and matching module 7 in the power amplification and matching unit to generate a first driving signal to the first ultrasonic motor 11 to be controlled;

[0031] The output signal of the second EPWM module 4 is processed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com