A device and method for electrically accelerated concrete dissolution test under high hydraulic gradient

A test method, hydraulic gradient technology, applied in the field of simulation test, can solve the problem of high sealing performance of the corrosion test chamber, and achieve stable electrochemical potential energy, good sealing performance and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

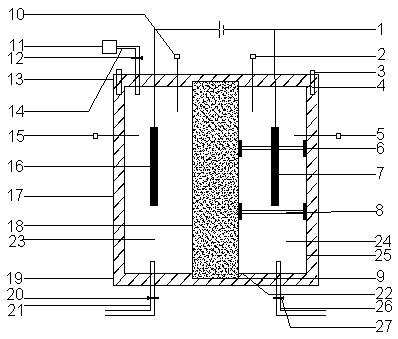

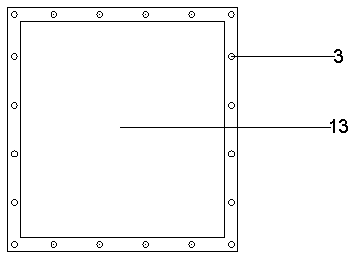

[0041] Such as figure 1 As shown, an electrically accelerated concrete corrosion test device under a high hydraulic gradient includes a test chamber, an external press 11, an external power source 2 and test electrodes.

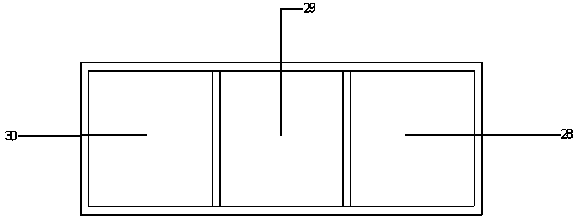

[0042] At least one pressure test chamber is arranged in the test chamber, preferably 3 pressure test chambers, and the number of pressure test chambers is specifically set according to usage requirements. The 3 pressure test chambers are parallel to each other, such as image 3 As shown, they are pressure test room 1 28, pressure test room 2 29 and pressure test room 3 30 respectively. The 3 pressure test rooms can carry out 3 groups of tests at the same time, carry out controlled variable tests, and study under different pressures and different water temperatures, The corrosion of concrete specimens under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com