A Method for Evaluating Residual Life of Corrosion of Tower Metal Coating

A technology of metal coating and pole towers, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as poor accuracy and geographical restrictions, and achieve the effect of accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

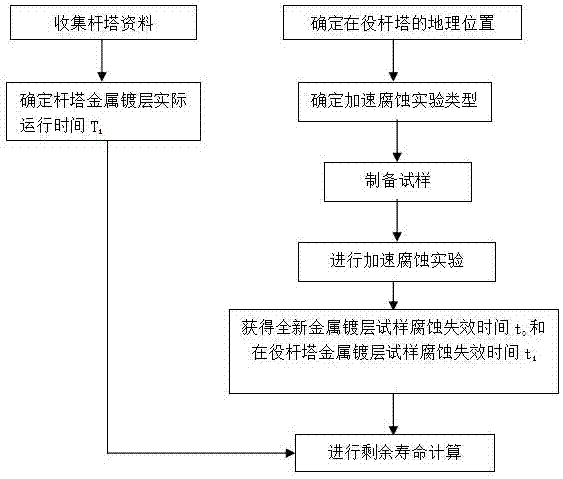

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Collect data

[0021] In July 2013, the original data and operation and maintenance data of the evaluated tower (a 220kV tower) were collected. By analyzing the collected data, it is determined that the anti-corrosion coating of the pole tower is a galvanized layer, and the commissioning time is July 2007. As of July 2013, the actual running time of the coating is T 1 for 72 months.

[0022] Step 2: Determine the type of accelerated corrosion test according to the distance between the tower and the coastline

[0023] The tower to be evaluated is not located in the coastal area, and the distance from the coastline is greater than 5000 meters. Therefore, the multi-factor coupling accelerated corrosion test is selected to measure the corrosion failure results of the new metal coating sample of the same type as the metal coating of the in-service tower and the metal coating sample of the in-service tower. It takes time t 0 , t 1 . By collecting and analyzing m...

Embodiment 2

[0026] In July, 2015, to embodiment 1 on pole tower (coating actual running time T 1 96 months) re-sampled at the same location, and carried out multi-factor coupling accelerated corrosion test to measure the corrosion failure time t of the brand-new metal coating sample and the metal coating sample of the tower in service. 0 , t 1 . Experimental parameter settings are the same as in Example 1. The experimental results are: the accelerated corrosion test time t for the new coating sample to reach corrosion failure 0 is 1440 hours, the accelerated corrosion time t required for the corrosion failure of the metal coating sample of the in-service tower 1 for 480 hours. The corrosion failure means that according to GB / T 6461-2002, the corrosion grade reaches below 3 (including grade 3).

[0027] Calculate the remaining life T of the metal coating on the tower through the evaluation formula for the remaining life of the tower; ; The calculation result is T=48 months, that is,...

Embodiment 3

[0029] Step 1: Collect data

[0030] In June 2013, the original data and operation and maintenance data of the evaluated tower (a 220kV tower) were collected. By analyzing the collected data, it is determined that the anti-corrosion coating of the tower is a galvanized layer, and the commissioning time is June 2008, and the actual operation time of the coating is T 1 for 60 months.

[0031] Step 2: Determine the type of accelerated corrosion test according to the distance between the tower and the coastline

[0032] The tower to be evaluated is 2.5 kilometers away from the coastline, which is less than 5000 meters, so the neutral salt spray test is selected to measure the corrosion failure time t of the new metal coating sample and the metal coating sample of the tower in service. 0 , t 1 . The experimental parameters are set according to GB / T 10125 "Artificial Atmosphere Corrosion Test-Salt Spray Test". The experimental results are: the accelerated corrosion test time t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com