Cooling mechanism for improving maintenance efficiency

A technology of heat dissipation mechanism and maintenance efficiency, applied in the directions of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of increased thermal resistance, inconvenient maintenance by maintenance personnel, and small contact area between the heat sink and the base, etc. The effect of size, improving heat dissipation capacity, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

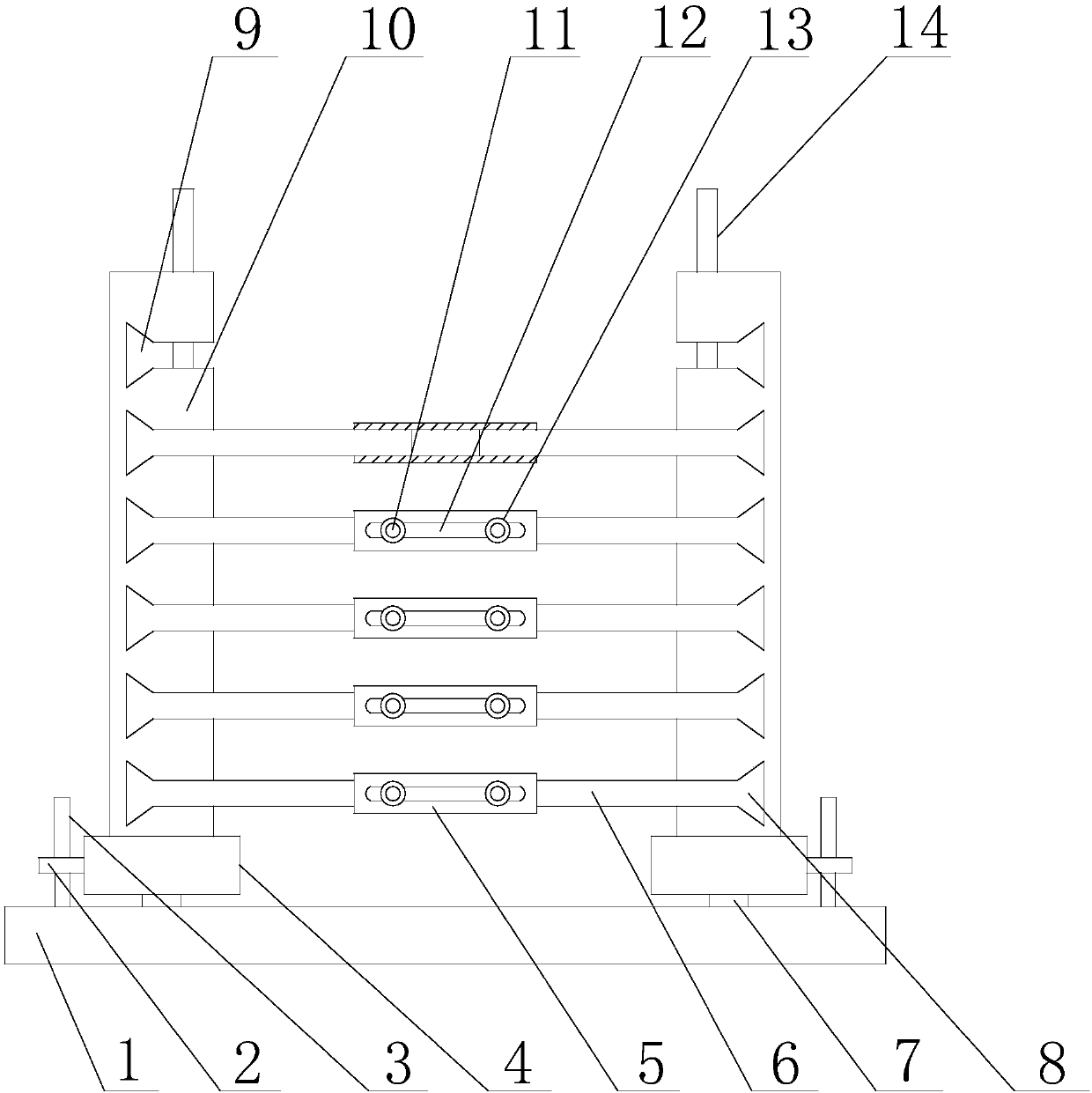

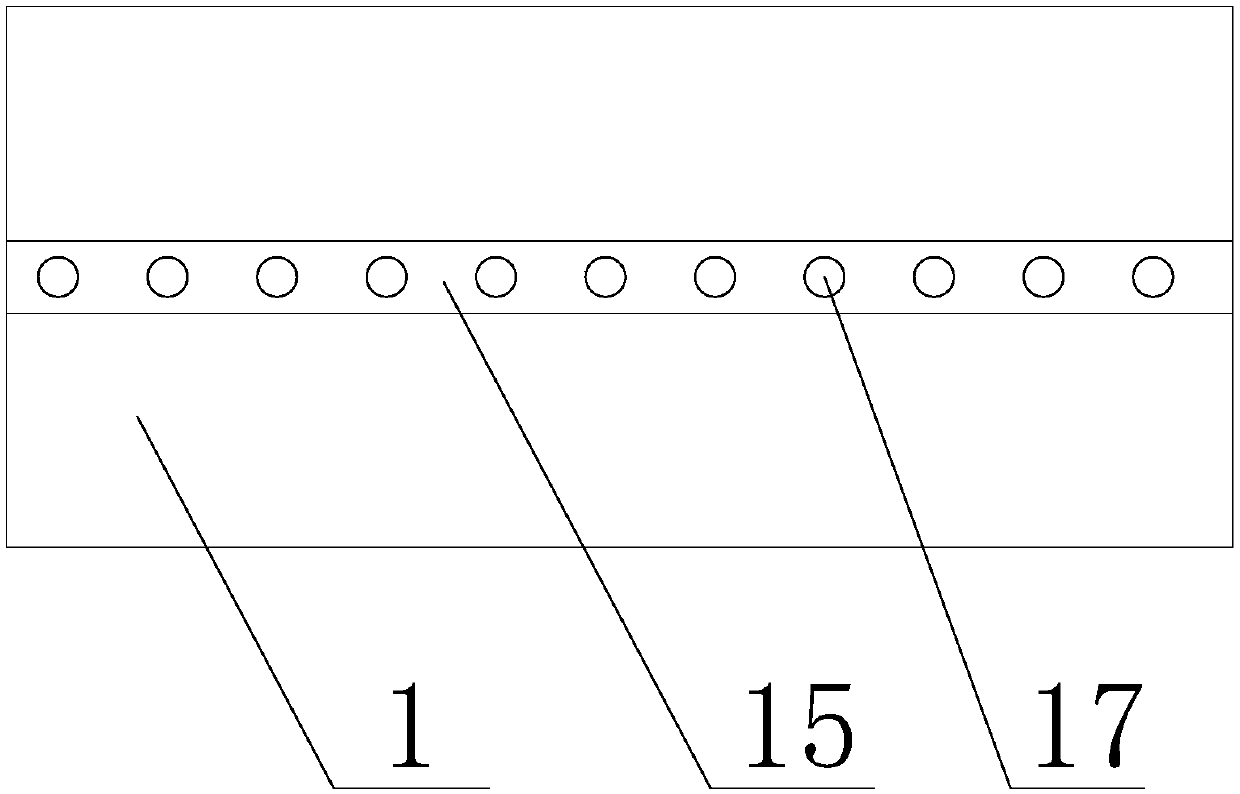

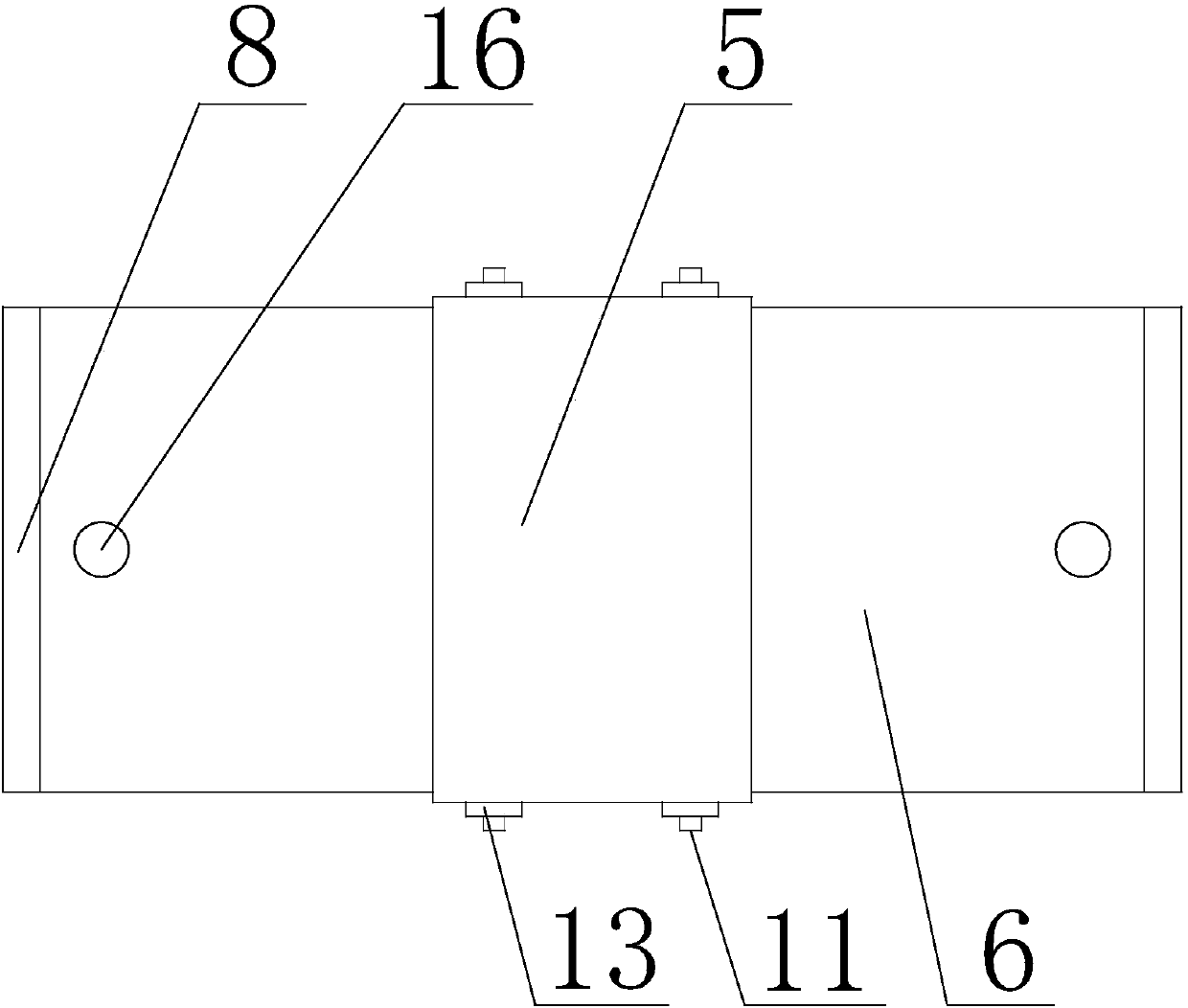

[0022] Such as Figure 1 to Figure 3 As shown, the cooling mechanism for improving the maintenance efficiency of the present invention includes a bottom plate 1 and a plurality of cooling fins 6, the top of the bottom 1 is provided with a chute 15, and two movable blocks 7 are arranged in the chute 15, and the movable block 7 and the The chute 15 is matched, the movable block 7 can move in the chute 15, and some blind holes 17 are evenly arranged in the chute 15, and the top of the movable block 7 is provided with a connecting block 4, and the connecting block 4 can move along with it. The block 7 moves together, and the outside of the connecting block 4 is also provided with a boss 2, and the boss 2 is provided with a positioning rod 3 matched with the blind hole 17, and the positioning rod 3 is vertically inserted on the boss 2 through threads, and rotates Positioning rod 3, positioning rod 3 can move in the blind hole 17 on the same vertical plane with positioning rod 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com