Method for automatically generating packing list on the basis of PLM (Product Life-cycle Management) system and SAP (Systems Applications and Products in data processing) system

An automatic generation and list technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of untimely, inaccurate packing list data, unnecessary maintenance of packing lists, etc., to avoid inconvenience. effect of necessity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better illustrate the present invention, the technical solution will be further described in conjunction with specific embodiments. Although these specific implementations have been described in the examples, they are not intended to limit the present invention. Those with ordinary knowledge in the technical field can make some changes without departing from the spirit and scope of the present invention. and retouching, so the scope of protection of the present invention should be defined by the claims.

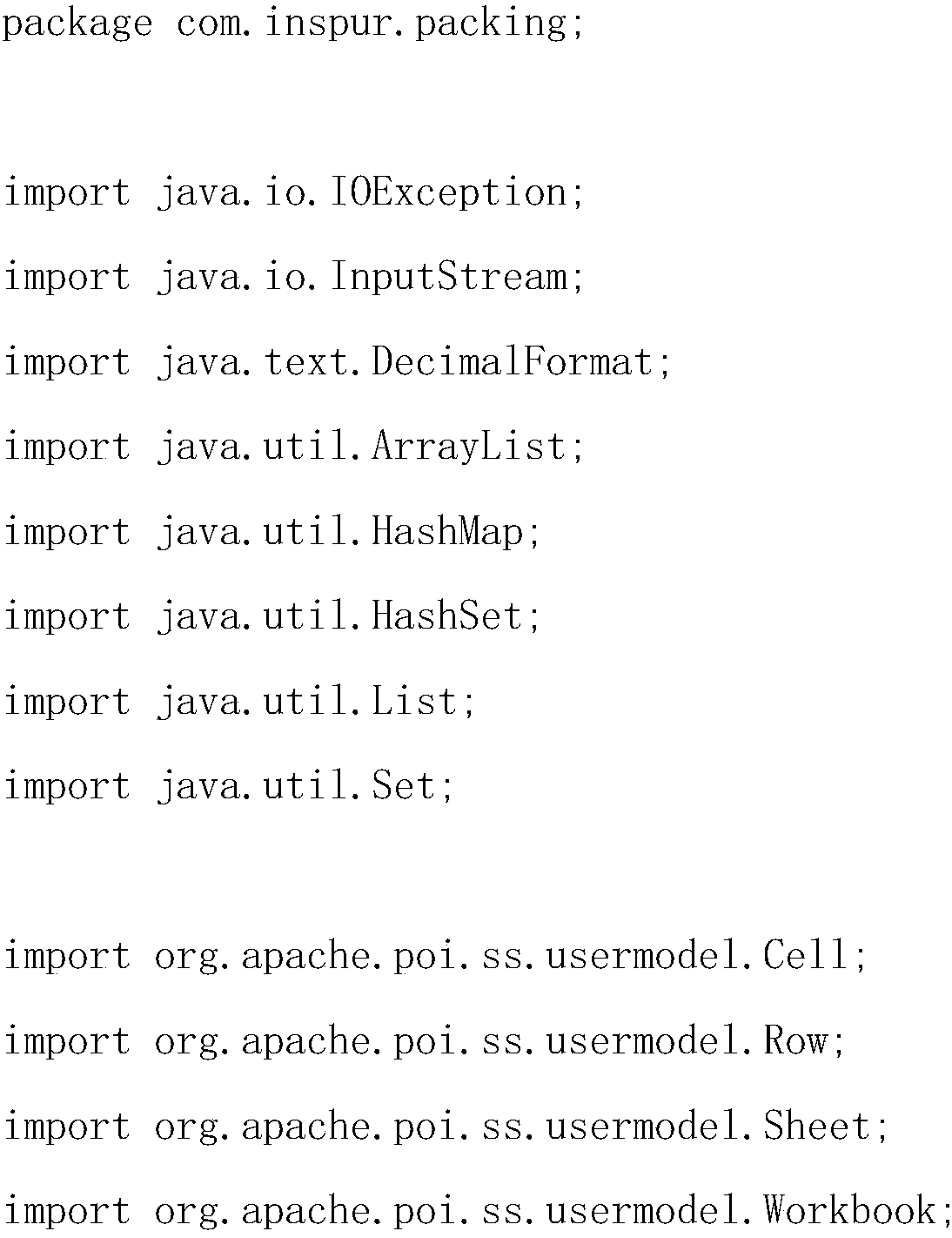

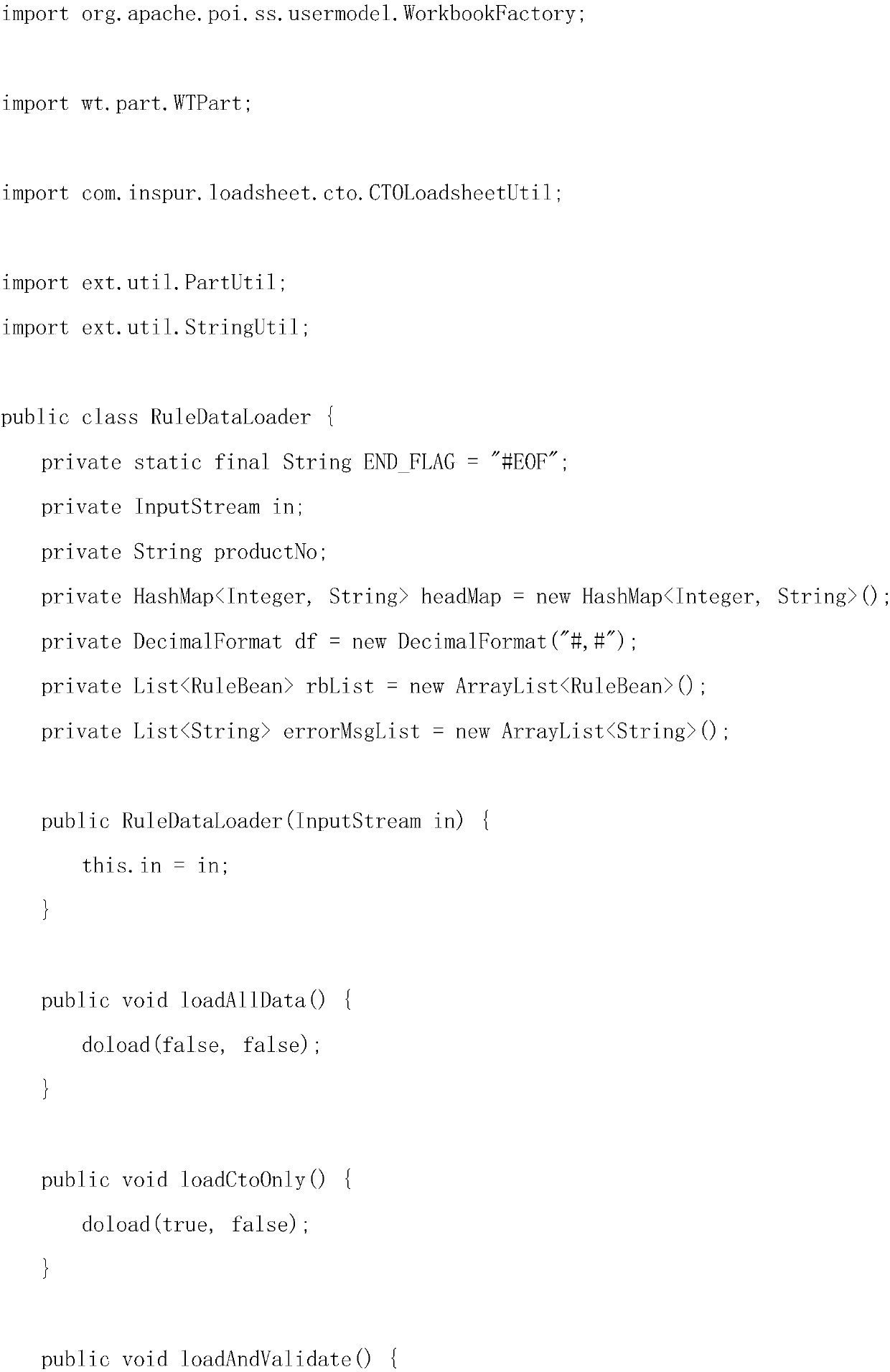

[0017] A method for automatically generating a packing list based on the PLM system and the SAP system of the present invention, the method is based on the PLM system and the SAP system of network communication, and its specific implementation process includes:

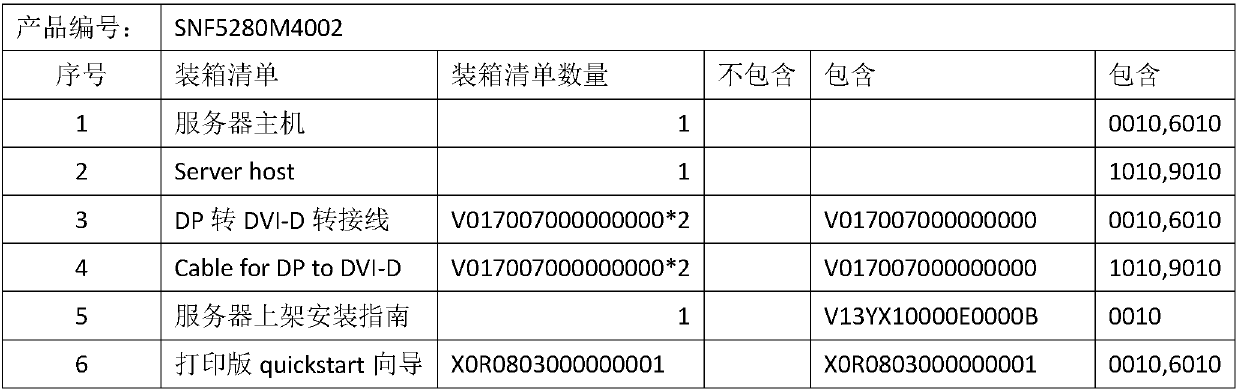

[0018] 1) During product design, the R&D personnel determine the content and rules of the packing list according to the product configuration, and the BOM maintenance engineer writes the packing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com