Production method of round conductor low-voltage power cable with high roundness

A circular conductor, low-voltage power technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor cable core roundness, insufficient product competitiveness, general appearance evaluation, etc., to achieve smooth surface, Effect of good physico-mechanical properties, reduced chance of damage to inner liner and outer sheath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

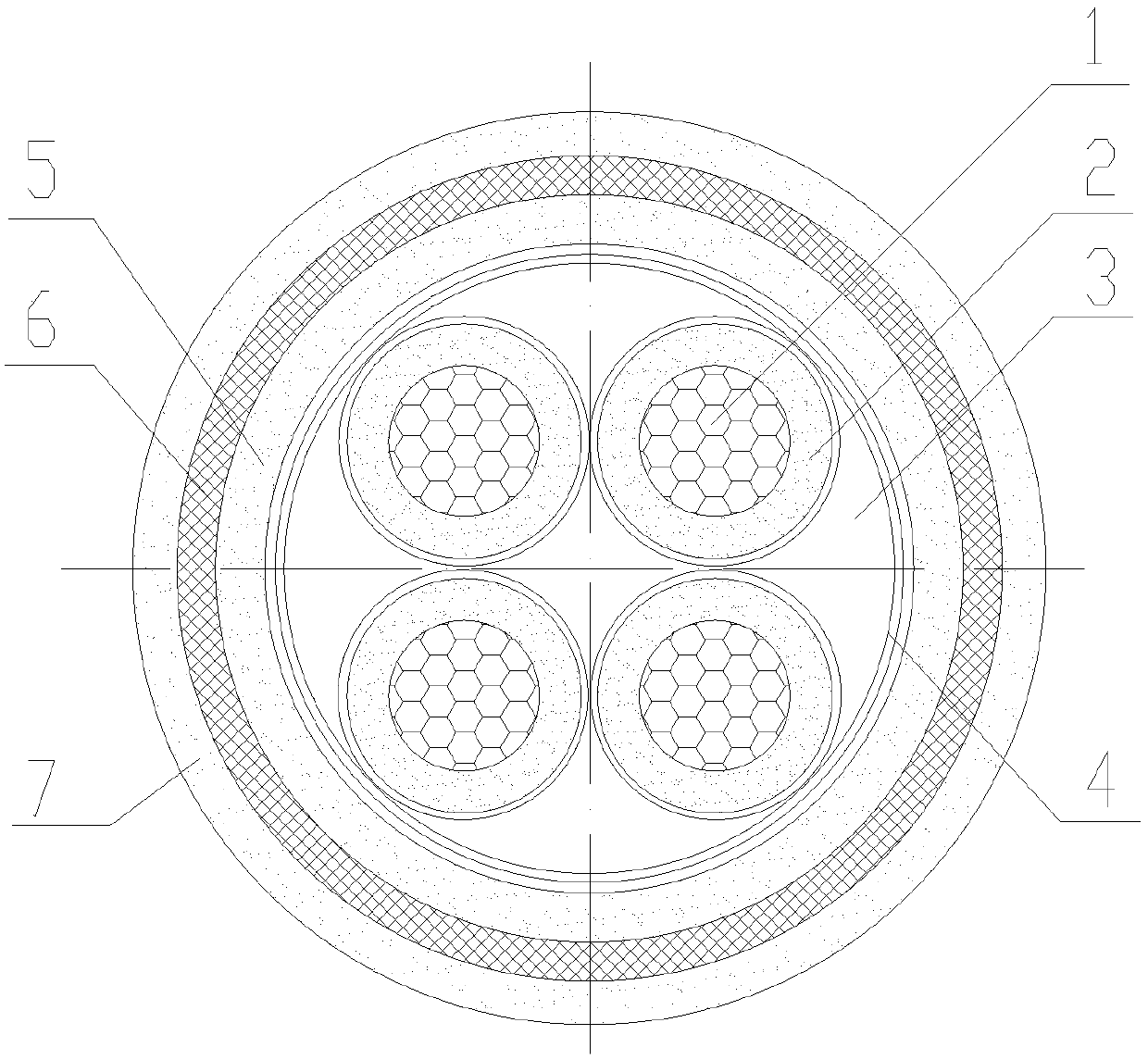

[0034] In this embodiment, a low-voltage power cable with circular conductors with high roundness is used as an example. The core part has 4 strands of circular shaped wire conductors 1 with an insulating layer 2 as an example. Its body structure is as follows: figure 1 As shown, a full circle is formed by special-shaped filling strips 3, a high-strength elastic tape 4 is arranged outside the full circle, an inner sheath 5 is provided outside the elastic tape, and an armor layer 6 is provided outside the inner sheath 5 , the outermost layer is provided with an outer sheath 7.

[0035] The diameters of the 4 round shaped wire conductors 1 are equal, and they are arranged in pairwise tangent positions. The special-shaped filling bar 3 is divided into 5 areas by 4 strands of circular shaped wire conducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com