Harvesting device for Chinese cabbage type crops

A technology for harvesting devices and crops, applied in agriculture, harvesters, agricultural machinery and implements, etc., can solve problems such as poor adaptability, poor operation quality, and lack of labor costs, and achieve good harvest operation quality, strong adaptability, and structural novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

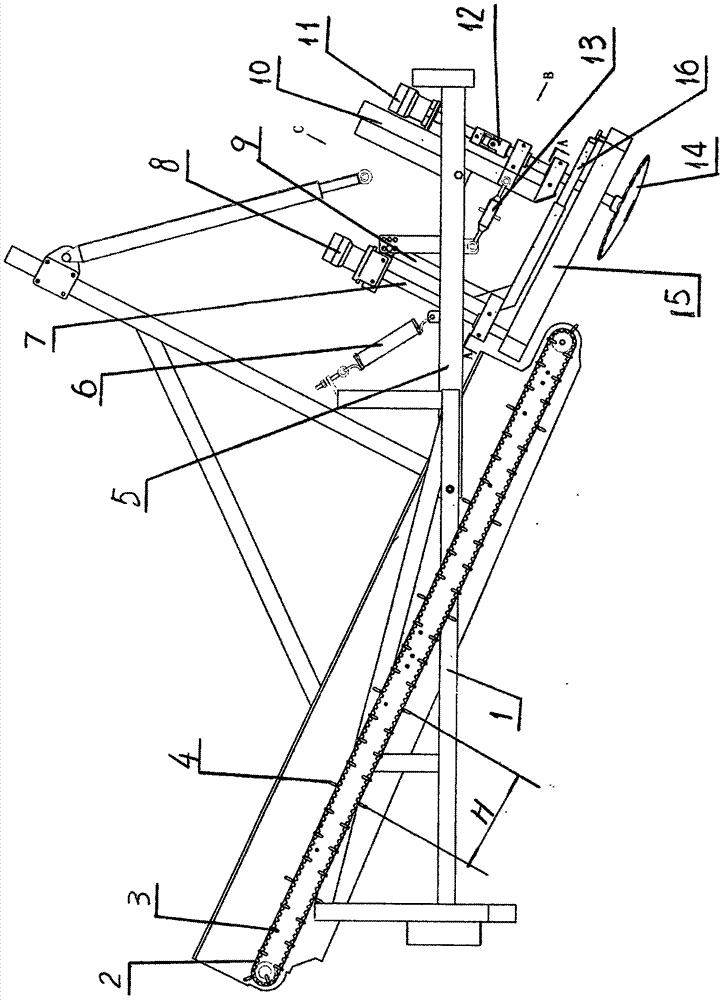

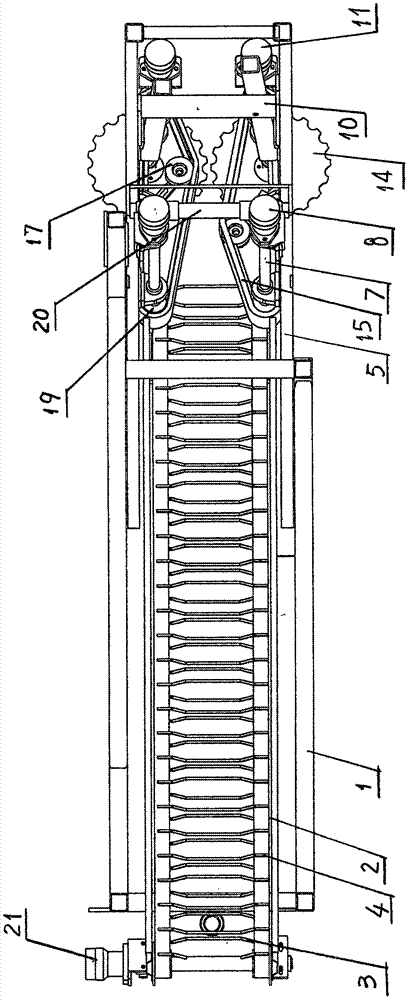

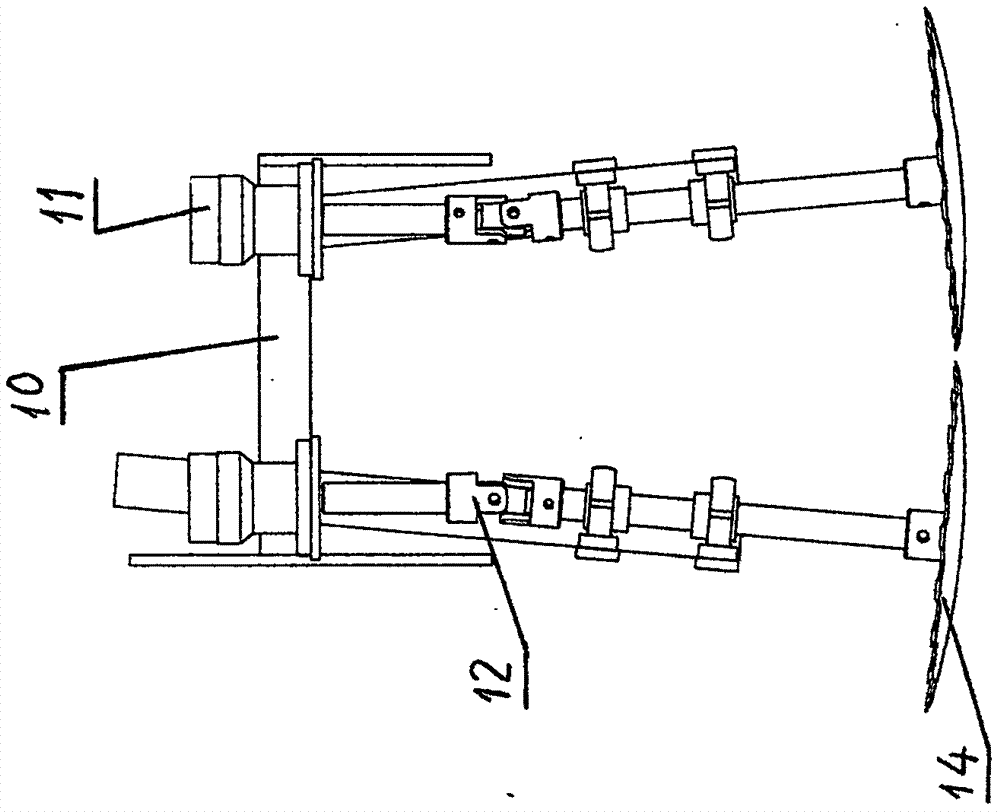

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A cabbage crop harvesting device, the main frame 1 is equipped with a grid-type conveyor belt assembly 2 with a grid-strip drive motor 21, and the grid-type conveyor belt assembly 2 is controlled by each other. It is composed of lower concave grid bars 3 and upper convex grid bars 4 arranged at intervals, and the spacing dimension H of adjacent upper convex grid bars 4 matches the external dimensions of cabbage crops; it can swing up and down on the front end of the main frame 1 The assembly frame 5 is hingedly installed, and the two ends of the tension spring 6 are respectively articulated with the main frame 1 and the assembly frame 5; The body frame 10 and the two ends of the inclination adjustment mechanism 13 are respectively hinged on the assembly frame 5 and the profiling cutting monomer frame 10, on the rear side of the assembly frame 5, located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com