Highly-efficient chicken essence raw material extruding and molding device

An extrusion molding and high-efficiency technology, which is applied in food forming, mixers with rotating stirring devices, transportation and packaging, etc., can solve the inconvenience of transferring chicken bouillon to other places, affecting the cleanliness of chicken bouillon forming, and low work efficiency, etc. problems, achieve the effect of reducing labor operation intensity, improving mixing efficiency and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

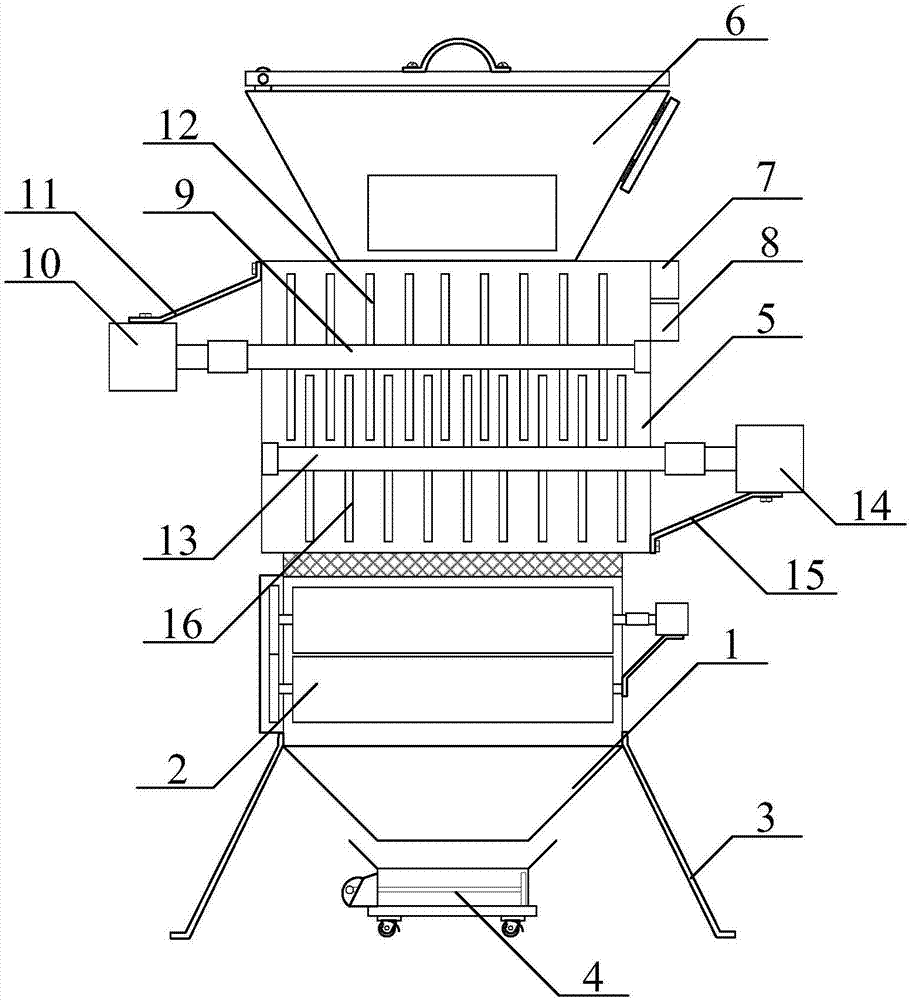

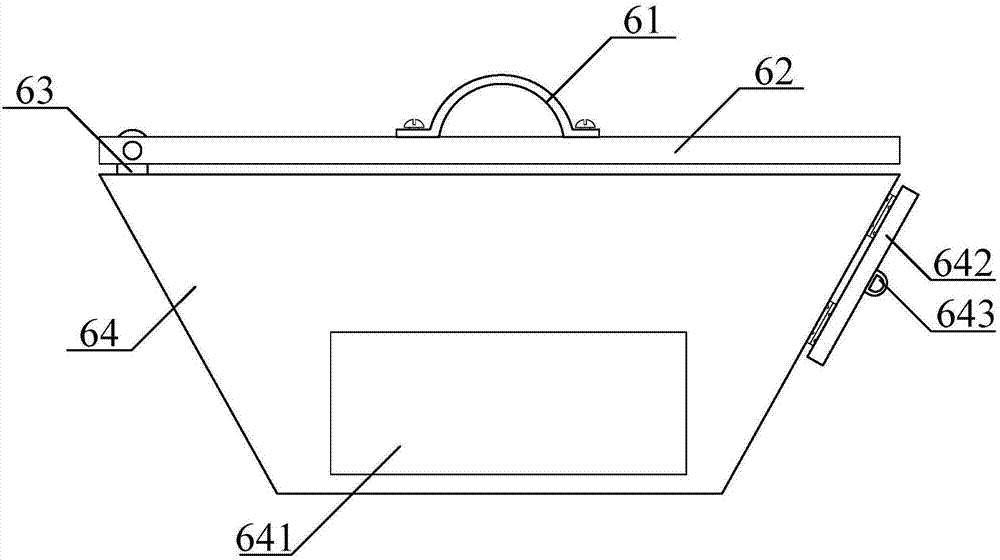

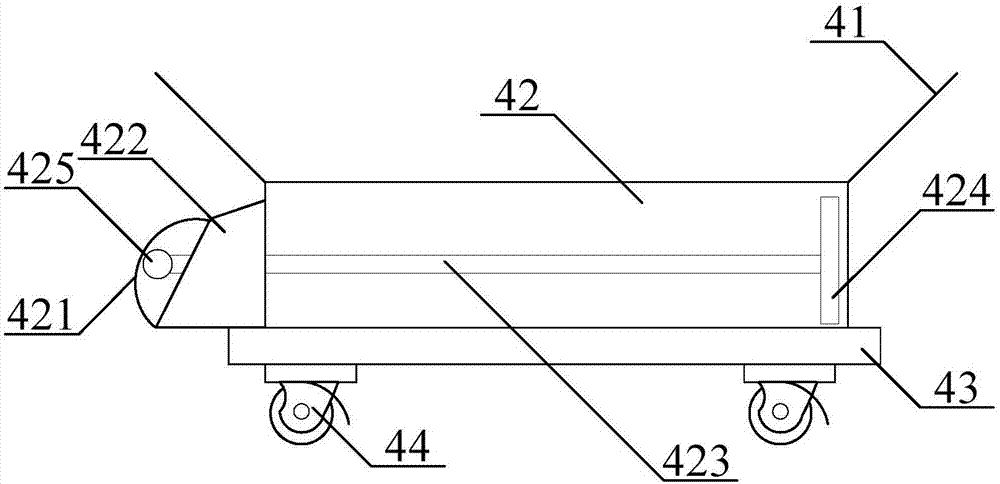

[0035] as attached figure 1 to attach Figure 4 shown

[0036]The invention provides a high-efficiency chicken bouillon raw material extrusion molding device, which includes a hopper 1, a heating roller structure 2, a tripod 3, a chicken bouillon forming and transporting vehicle 4, a mixing box 5, a dust-proof hopper structure 6, and a primary switch 7. Secondary switch 8, primary stirring shaft 9, primary stirring motor 10, primary support plate 11, primary stirring rod 12, secondary stirring shaft 13, secondary stirring motor 14, secondary support plate 15 and secondary Stirring rod 16, the bolts of the discharge hopper 1 are installed on the lower end of the heating roller structure 2; the bolts of the tripods 3 are respectively installed on the upper four corners of the heating roller structure 2; At the bottom of the discharge hopper 1; the bolts of the stirring box 5 are installed on the upper part of the heating roller structure 2; the bolts of the dust-proof hopper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com