Pattern making method for decorative sleeves of garment

A technology for sleeves and clothing, applied in the field of making decorative sleeves of clothing, can solve the problems of incapable of industrialized production, time-consuming and labor-intensive, and affect product quality, etc., to achieve mass production suitable for large-scale production, improve product quality, line outline smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

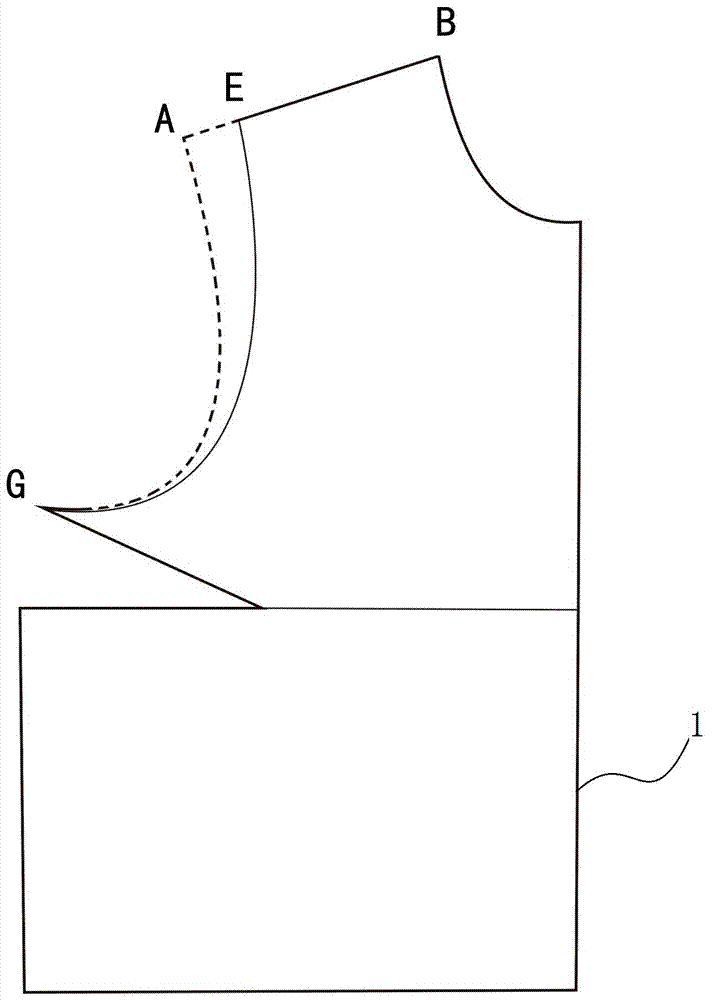

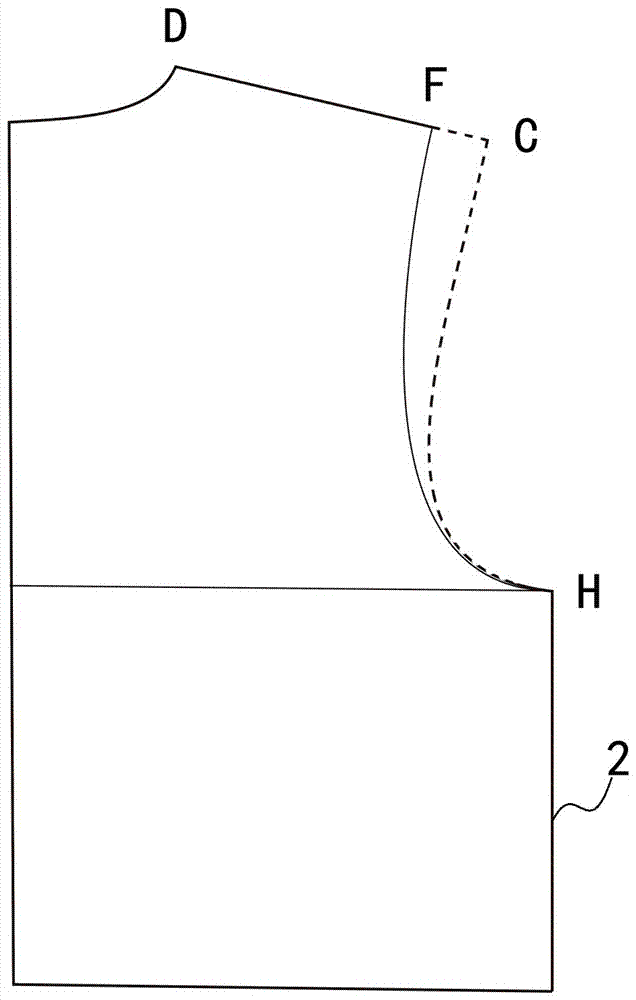

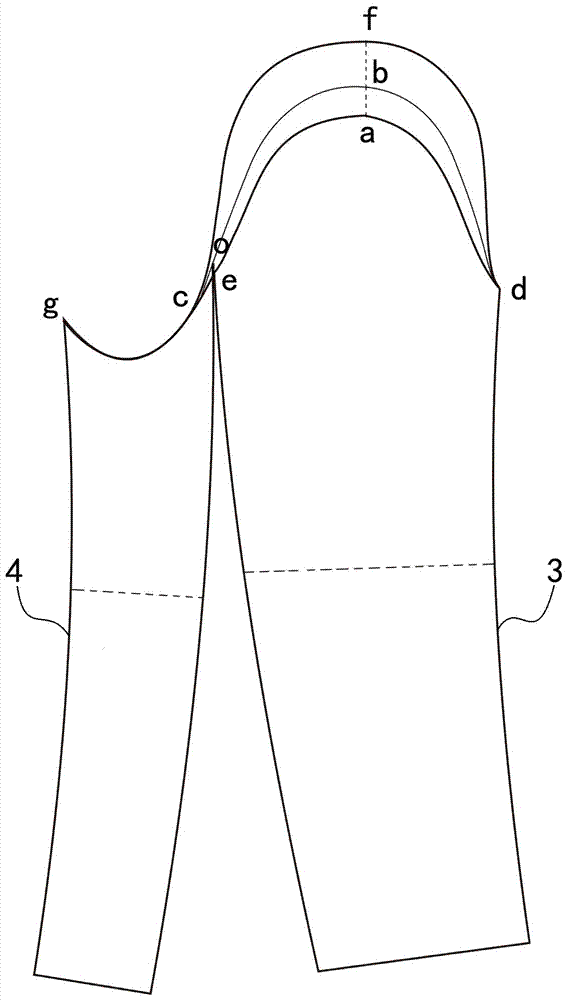

[0040] as attached Figure 1-4 As shown, the present invention includes a front panel template 1, a rear panel template 2, a large sleeve template 3 and a small sleeve template 4; wherein: the front shoulder line of the front panel template 1 is AB, the front armhole line is AG, and the back panel template 2 The back shoulder line is CD, and the back armhole line is CH; place the cuffs of the large sleeve model 3 and the small sleeve model 4 flush, and the large outer sleeve suture of the large sleeve model 3 corresponds to the small outer sleeve suture of the small sleeve model 4 Its corresponding apex intersects at point e; the sleeve mountain line of the large sleeve model 3 is ed, the sleeve mountain apex is point a, and the sleeve bottom line of the small sleeve model 4 is ge;

[0041] Plate making method of the present invention adopts following steps:

[0042] 1. Adjust the position of the front and rear armhole lines: as attached Figure 1-2 As shown, move the inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com