Fabricated three-dimensional beam-column element prefabricated component

A three-dimensional beam-column, prefabricated component technology, applied in building components, building structures, protective buildings/shelter, etc., can solve problems such as node reliability decline, improve prefabrication rate, reduce seismic force, save energy The effect of social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

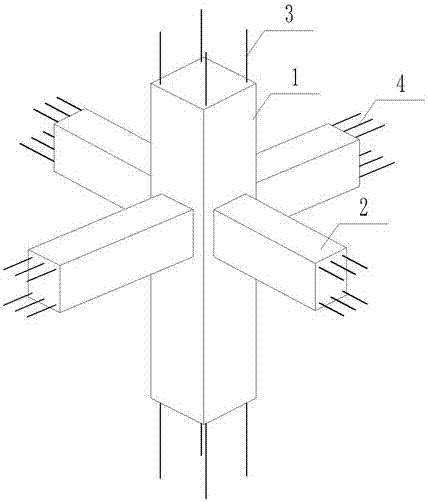

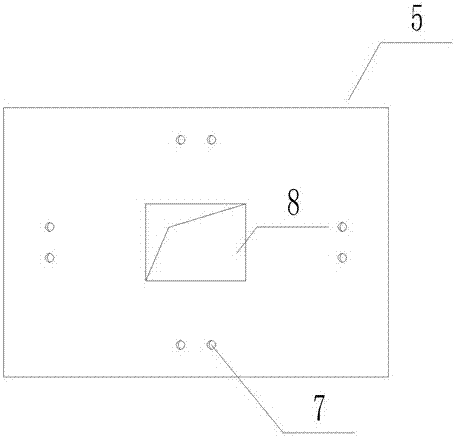

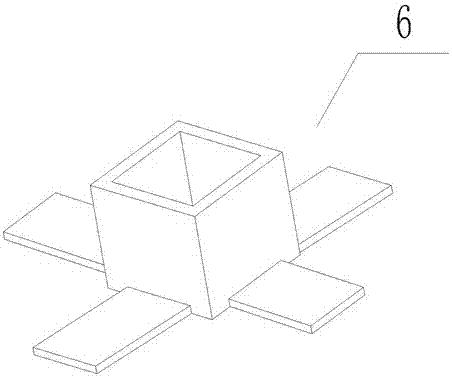

[0022] 1. An assembled three-dimensional beam-column unit prefabricated member, comprising a column unit 1 and four beam units 2; at the position away from the top and / or bottom end of the column unit 1, the beam unit 2 and the column unit 1 are cast as a whole, and the beam Element 2 has beam element reinforcement 4 connected to other components, and column element 1 has column element reinforcement 3 connected to other components. Adjacent beam elements 2 are perpendicular to each other, the top elevation is the same, and the plane of column element 1 and beam element 2 is perpendicular.

[0023] 2. An assembled three-dimensional beam-column unit prefabricated component, comprising a column unit 1 and three beam units 2; at the position away from the top and / or bottom end of the column unit 1, the beam unit 2 and the column unit 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com