Battery separator, lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and battery diaphragms, which is applied in the fields of lithium-ion batteries and their respective preparations and battery diaphragms, can solve the problems of short-circuit heat shrinkage and poor air permeability of battery diaphragms, and improve the short-circuit rate of bare cells and finished cells Effects of short-circuiting, improving air permeability, and improving macroporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

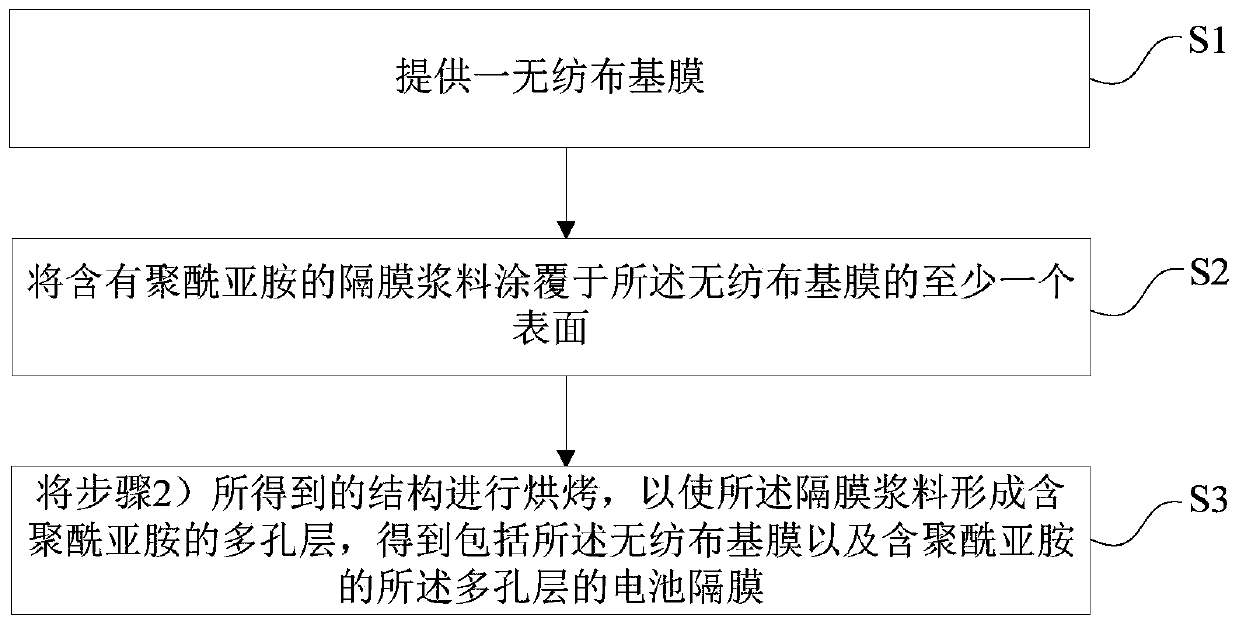

[0036] Such as figure 1 As shown, the present invention provides a kind of preparation method of battery diaphragm, comprises the steps:

[0037] 1) Provide a non-woven base film 11;

[0038] 2) coating the diaphragm slurry containing polyimide on at least one surface of the non-woven fabric base film 11; and

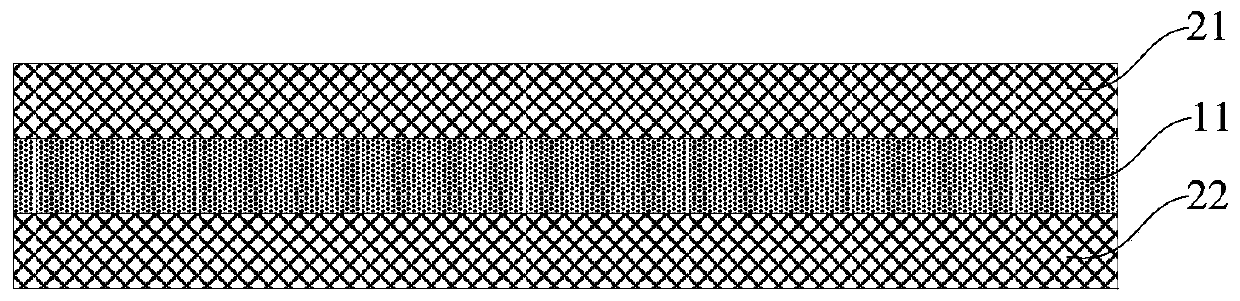

[0039] 3) Bake the structure obtained in step 2), so that the separator slurry forms porous layers 21, 22 containing polyimide, and obtains the non-woven fabric base 11 and the polyimide-containing porous layer. The porous layer 21, 22 of the battery separator.

[0040] It should be noted that the present invention provides a method for preparing a battery separator, in which a slurry containing polyimide is coated on a non-woven fabric, on the one hand, it can be used to improve the high temperature resistance of the final coated product . In addition, during the charging and discharging process of the lithium-ion battery, the polyimide-coated non-woven fabric ensu...

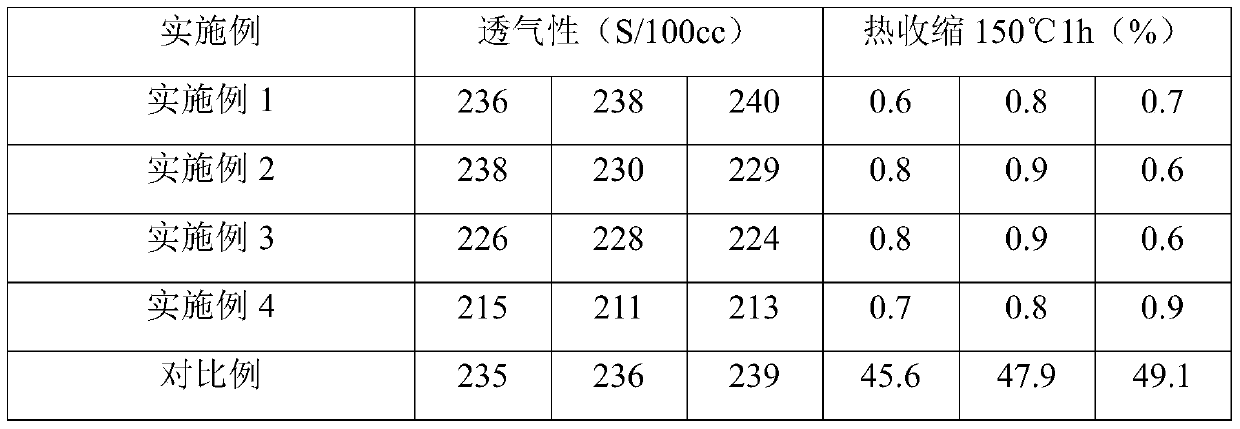

Embodiment 1

[0071] A) Weigh 0.1Kg of co-solvent LiCl and add it to 3Kg of the first solvent NMP and stir until it is completely dissolved. Slowly add 0.1Kg of dispersant polyethylene oxide powder with a molecular weight of 100,000-1 million while stirring, and 0.1Kg of oxidized Stir the aluminum until it is evenly dispersed, then slowly add 7Kg of polyimide solution (polyimide content is 8%) and stir evenly to prepare the polyimide slurry;

[0072] B) Take a non-woven fabric base film with a thickness of 18 μm, and use a gravure roller coating method to coat polyimide on one side of the base film at a coating speed of 12m / min, and dry it in a three-stage oven after passing through water , the oven temperatures at all levels are 50°C, 60°C, and 55°C respectively. After drying, a polyimide-coated lithium-ion battery separator can be obtained. The thickness of the polyimide-coated lithium-ion battery separator is 22 μm, the coating thickness is 4 μm.

Embodiment 2

[0074] A) Weigh 0.1Kg of co-solvent LiCl and add it to 3.5Kg of the first solvent DMAC and stir until completely dissolved, while stirring, slowly add 0.1Kg of dispersant polyethylene oxide powder with a molecular weight of 10-1 million, and 0.2Kg of Alumina is stirred until it is evenly dispersed, then slowly add 6.5Kg of polyimide solution (polyimide content is 8%) and stir evenly to obtain polyimide slurry;

[0075] B) Take a non-woven fabric base film with a thickness of 18 μm, and use a gravure roller coating method to coat polyimide on one side of the base film at a coating speed of 12m / min, and dry it in a three-stage oven after passing through water , the oven temperatures at all levels are 50°C, 60°C, and 55°C respectively. After drying, a polyimide-coated lithium-ion battery separator can be obtained. The thickness of the polyimide-coated lithium-ion battery separator is 22 μm, the coating thickness is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com