Clamp device for circuit de-icing

A clamping device and line-type technology, which is applied to coupling devices, components of connecting devices, circuits, etc., can solve the problems of time-consuming and labor-intensive shorting, poor operation safety, and low ice-melting efficiency, and achieve convenient operation and low cost , Improve the effect of operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

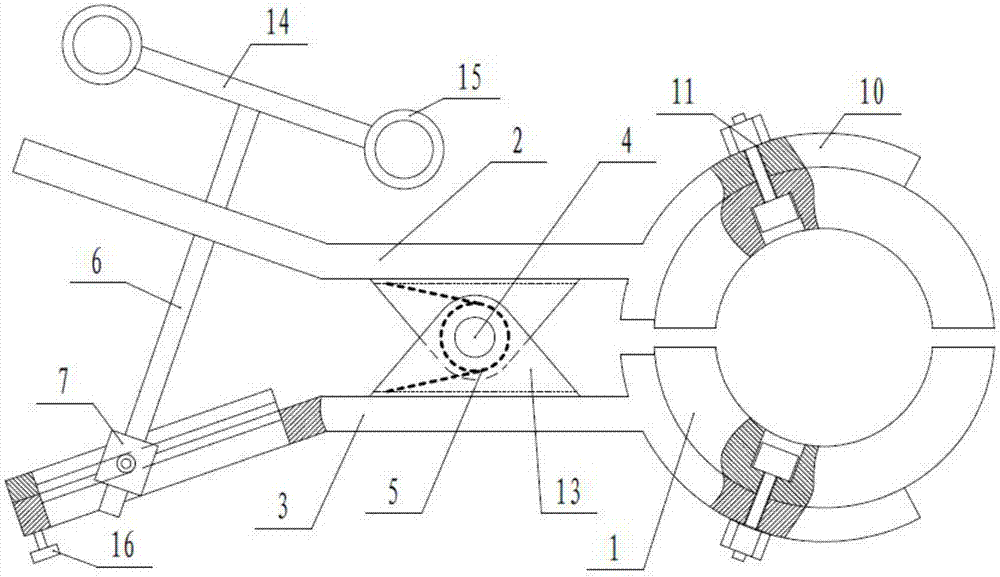

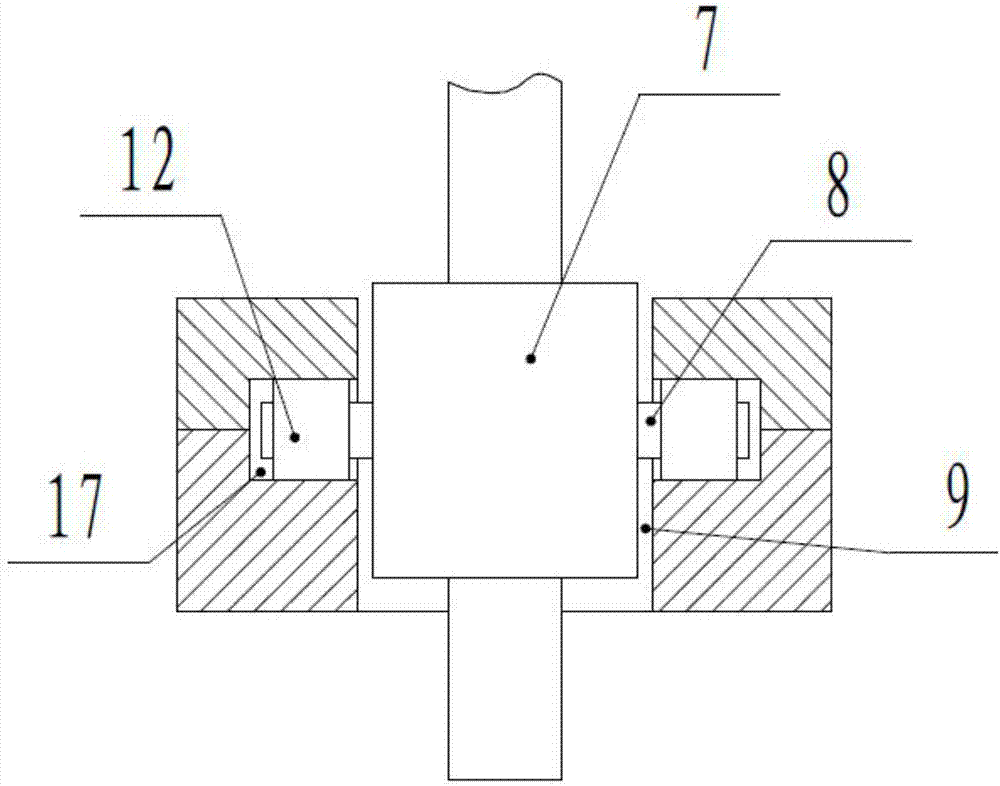

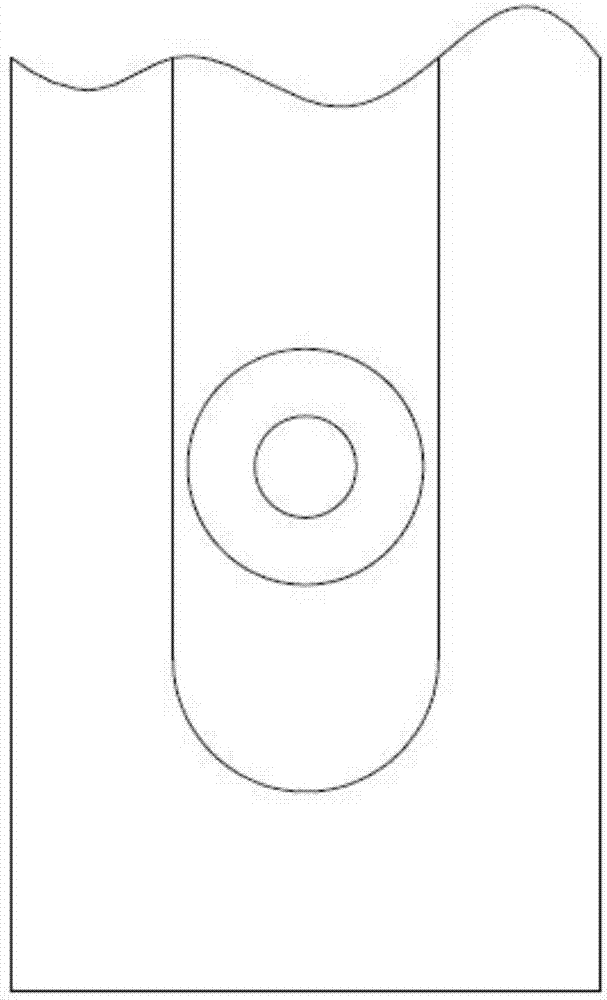

[0018] Example: such as Figure 1-Figure 3 As shown, a line-type ice-melting clamping device includes two conductive arc-shaped clamping pieces 1, and the two arc-shaped clamping pieces 1 are symmetrically installed on the front ends of the clamping plate 1 2 and the clamping plate 2 3 respectively, and the clamping plate The first 2 and the clamping plate 2 3 are connected by the hinge shaft 4, the hinge shaft 4 is provided with a reset spring 5 and the free state of the clamping plate 1 2 and the clamping plate 2 3 is closed, and the tail end of the clamping plate 1 2 is screw connected There is a dismounting screw 6, and the end of the dismounting screw 6 protruding toward the clamping plate 2 3 is connected to a screw nut 7 that can rotate and slide along the length direction of the clamping plate 2 3, and the screw nut 7 is connected to the clamping plate 1 2 The threaded hole connecting the disassembly screw 6 rotates in the opposite direction. This device is used to gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com