Deviation correcting device for hoisting large building components

A technology of building components and deflection correction devices, which is applied in the directions of transportation, packaging, and load hanging components, etc., can solve the problems that building components are prone to deviation, etc., and achieve the effects of simple structure, enhanced safety, and ingenious methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

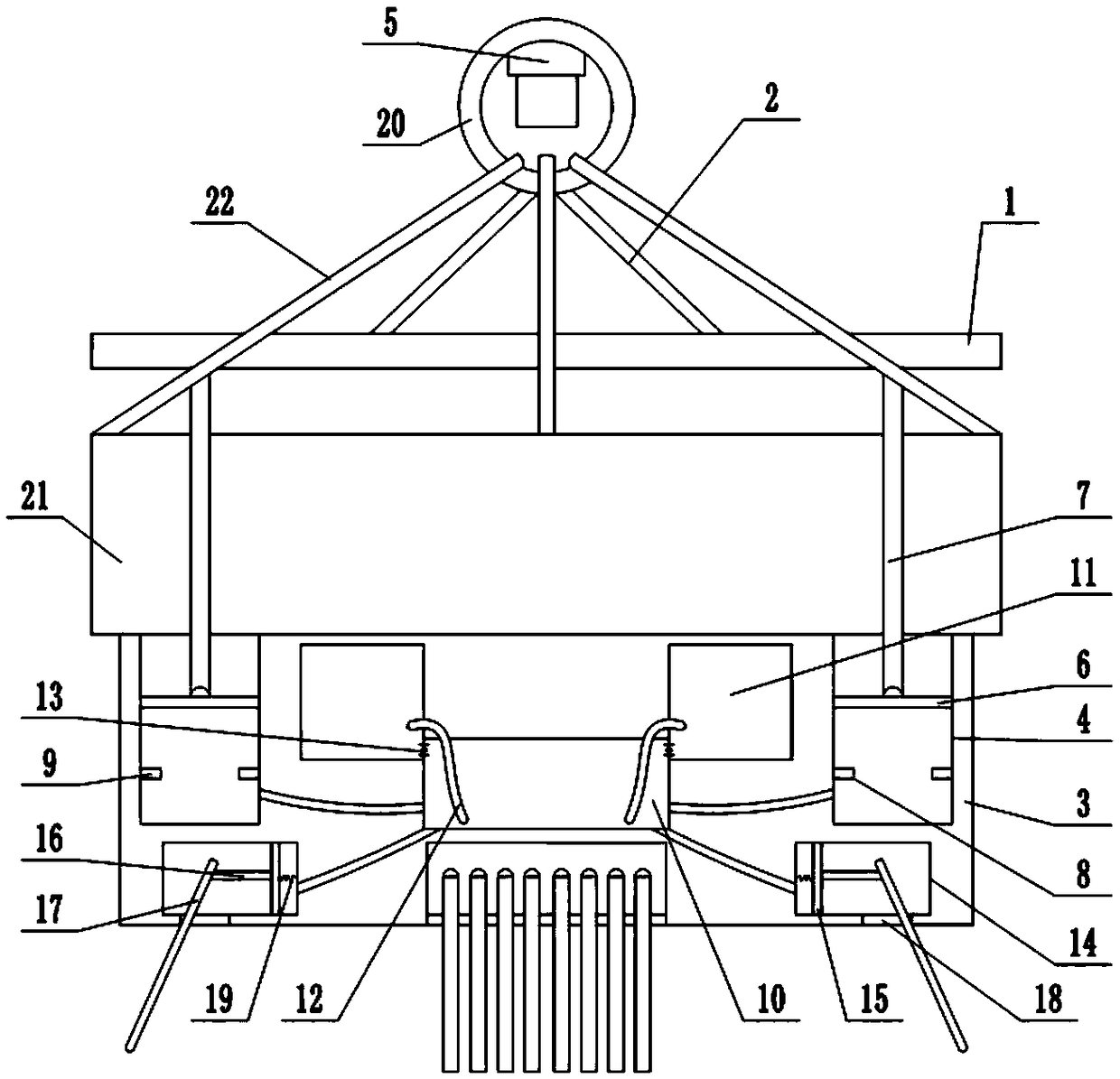

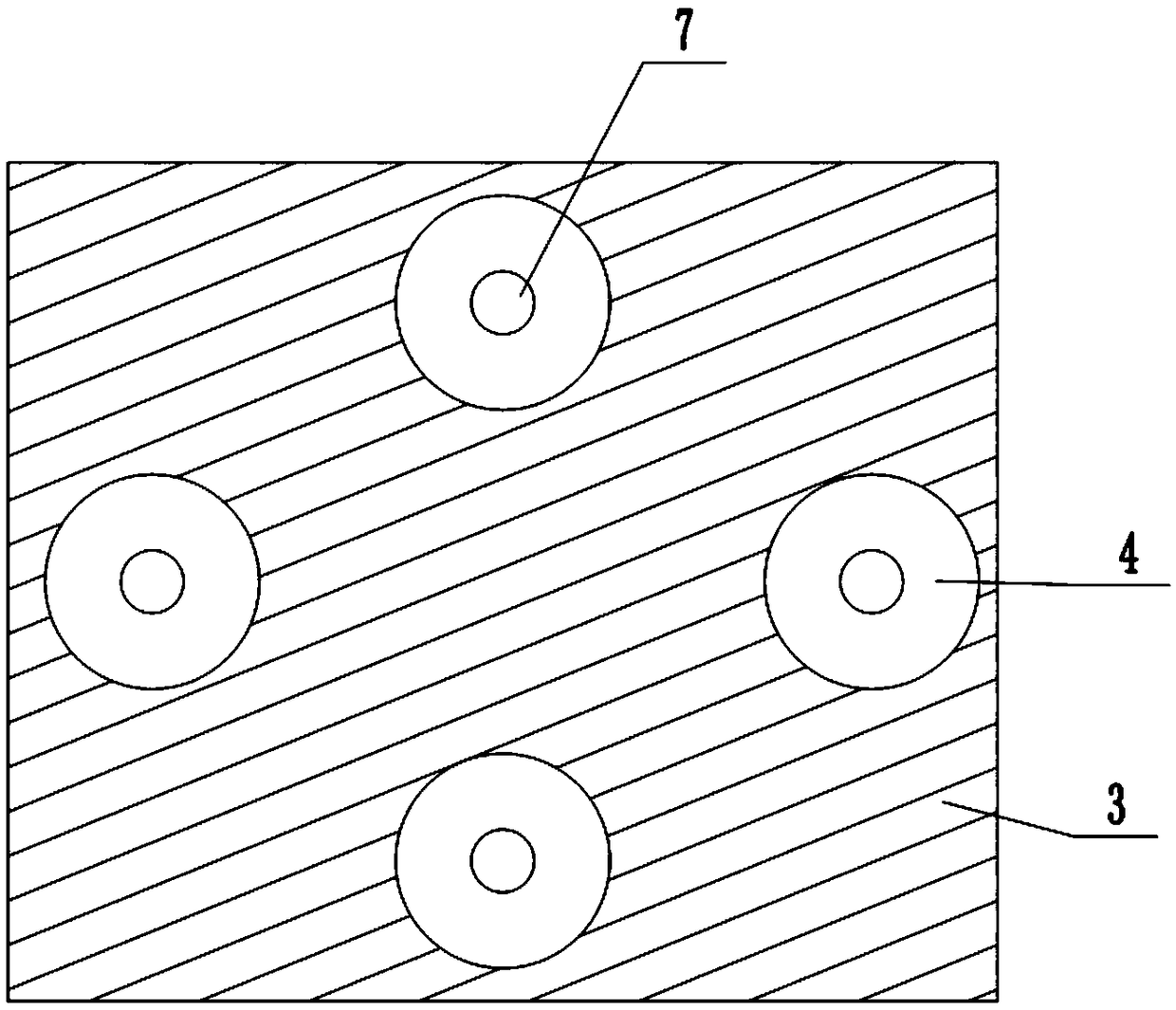

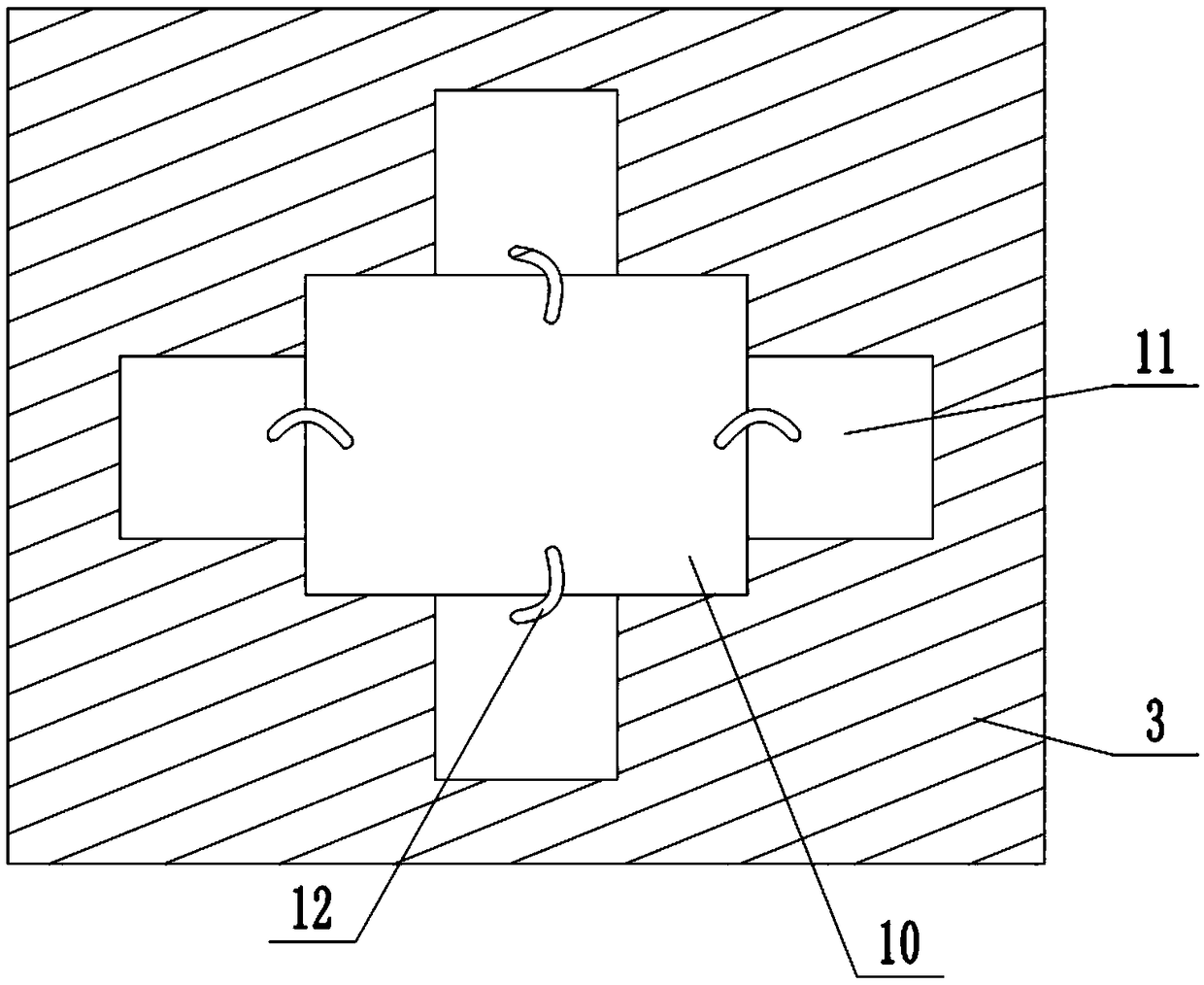

[0022] The reference signs in the drawings of the description include: fixed plate 1, support rod 2, box body 3, control cylinder 4, locking cylinder 5, piston plate 6, piston rod 7, locking switch 8, water supply switch 9, central cavity Chamber 10, counterweight cavity 11, water adding pipe 12, water discharge valve 13, chute 14, slide plate 15, push plate 16, resisting rod 17, swing port 18, spring 19, suspension ring 20, suspension body 21, sling 22,

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] The deviation correcting device for hoisting large building components is mainly composed of a fixed plate 1, a box body 3, a control cylinder 4, a deviation correcting unit, and a pressing unit. The fixed plate 1 is located above the suspension body 21 , and three poles 2 are welded between the fixed plate 1 and the suspension ring 20 . as attached figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com