Assembly-type down-penetration tunnel

A prefabricated, tunnel technology, applied in tunnels, tunnel linings, underground chambers, etc., to achieve the effect of simple assembly structure, high construction efficiency, and guaranteed wall structure strength and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

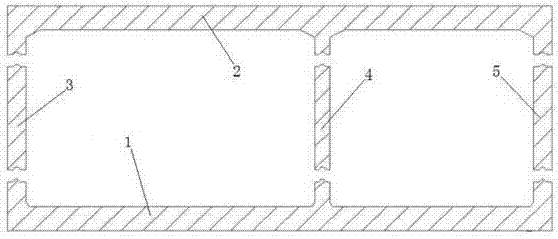

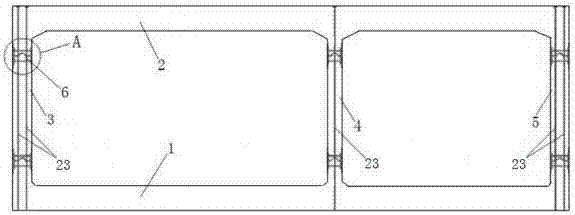

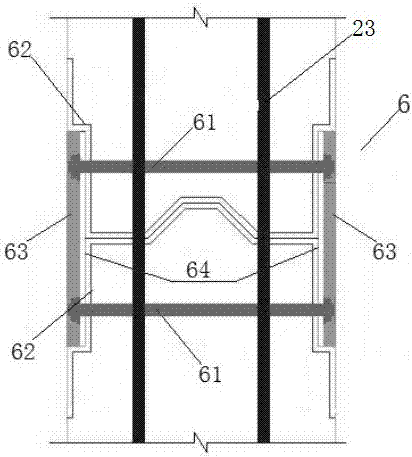

[0050] Such as Figure 1 to Figure 3 As shown, the prefabricated underpass tunnel of this embodiment includes a plurality of prefabricated blocks forming the tunnel section, the prefabricated blocks include a bottom plate 1, a top plate 2 and vertical walls, the bottom plate 1 is a W-shaped structure, and the The top plate 2 is an M-shaped structure corresponding to the bottom plate 1. The vertical wall includes a left vertical wall 3, a right vertical wall 5, and a middle vertical wall 4. The joint between the top plate 2 and the vertical wall is set as a concave-convex shear key. structure, and an assembled reinforcing member 6 is also provided at the seam. Further, the joint between the bottom plate 1 and the vertical wall is also provided with a shear key structure with concave and convex fit.

[0051] Further, the joint between the prefabricated blocks is defined as a horizontal joint, and the shear key structure includes a raised shear key and a groove adapted to the sh...

Embodiment 2

[0060] Such as Figure 1 to Figure 9 As shown, according to the prefabricated underpass tunnel described in Embodiment 1, this embodiment is designed for another problem of the prefabricated underpass tunnel. For the underground tunnel engineering with changing conditions, there are different degrees of deformation in each tunnel section Or subsidence is possible, so a deformation joint needs to be set every 20-30m along the length of the tunnel, and the deformation joint joint form of the underpass tunnel made by the commonly used cast-in-place method is not suitable for the prefabricated underpass tunnel, especially if there are The joints at the large arc corners of the tunnel are jointed, so the waterproofness of the deformation joints and the multi-directional deformation allowance design, the solution of this embodiment is: including the deformation joints set between the tunnel sections, and equipped with a deformation joint waterproof device , the deformation joint is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com