An intelligent spray paint control method based on pressure detection

A pressure and pressure value technology, applied in the field of intelligent spray painting control based on pressure detection, can solve the problems of affecting painting efficiency and effect, environmental pollution, and high cost, so as to reduce the time of spraying operation, improve the spraying effect, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

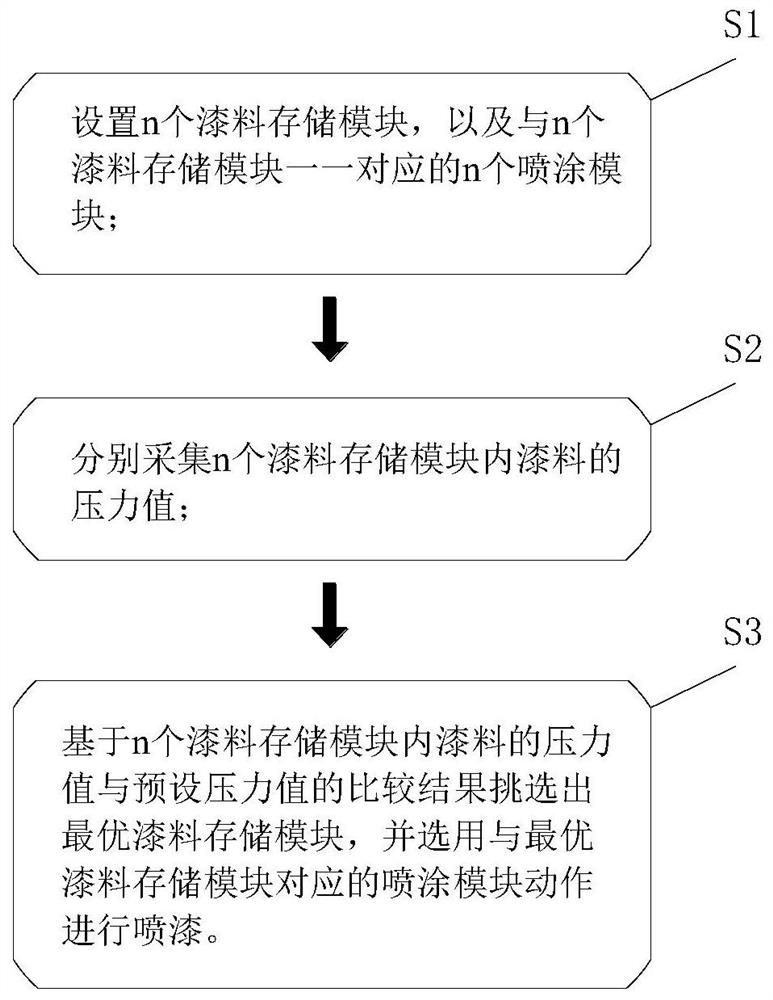

[0024] Such as figure 1 as shown, figure 1 It is an intelligent spray painting control method based on pressure detection proposed by the present invention.

[0025] refer to figure 1 , the intelligent spray paint control method based on pressure detection proposed by the present invention comprises the following steps:

[0026] S1. Setting n paint storage modules and n spraying modules corresponding to the n paint storage modules;

[0027] S2. Collect the pressure values of the paint in the n paint storage modules respectively;

[0028] In this embodiment, step S2 specifically includes:

[0029] The pressure values of the paint in the n paint storage modules are respectively collected by n collection modules, and the n collection modules correspond to the n paint storage modules one by one;

[0030] Preferably, among the n acquisition modules, any one acquisition module includes a plurality of acquisition sub-modules, and the installation positions of the plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com