High angularity ball joint assembly

一种球形接头、组件的技术,应用在连接、枢轴连接、轴承组装等方向,能够解决快速磨损、高磨损率和撕裂率、噪声和妨害等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In the following detailed description, reference is made to the accompanying drawings which form a part hereof. In the drawings, similar symbols typically identify similar components, unless context dictates otherwise. The illustrative embodiments described in the detailed description and drawings are not meant to be limiting. Other embodiments may be utilized, and other changes may be made, without departing from the spirit or scope of the subject matter presented here. It will be readily understood that aspects of the disclosure as generally described herein and illustrated in the drawings may be arranged in a wide variety of different configurations, substitutions, combinations and designs, all of which are expressly contemplated and constitute a part of this disclosure.

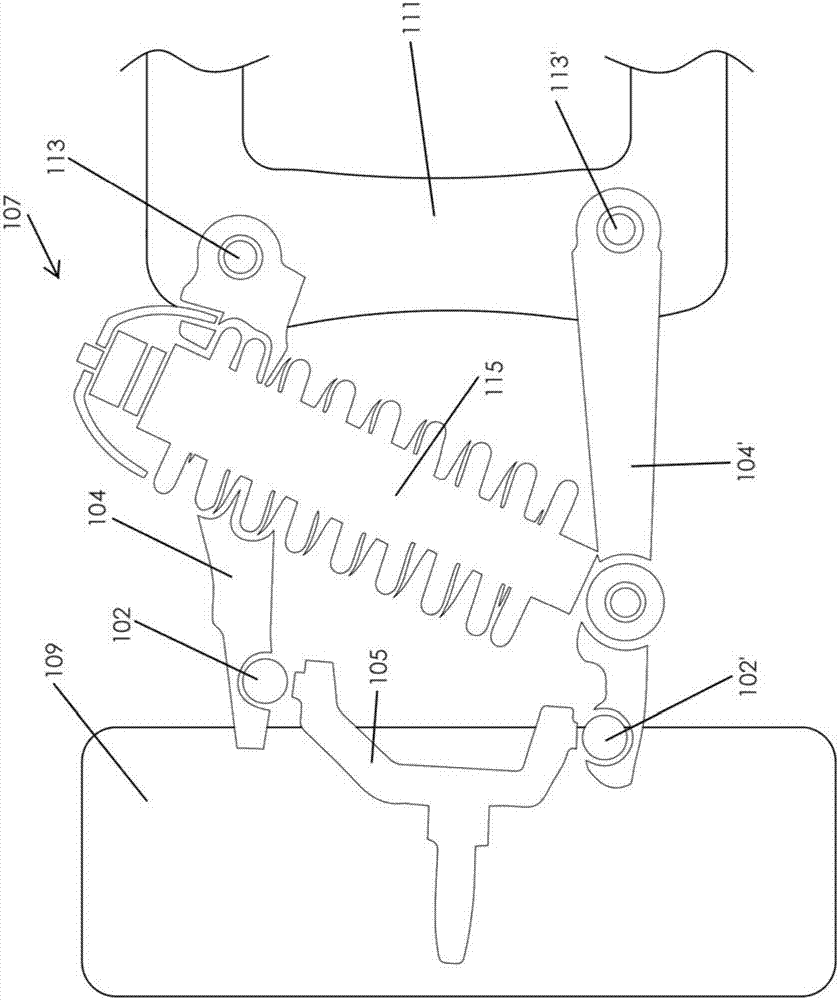

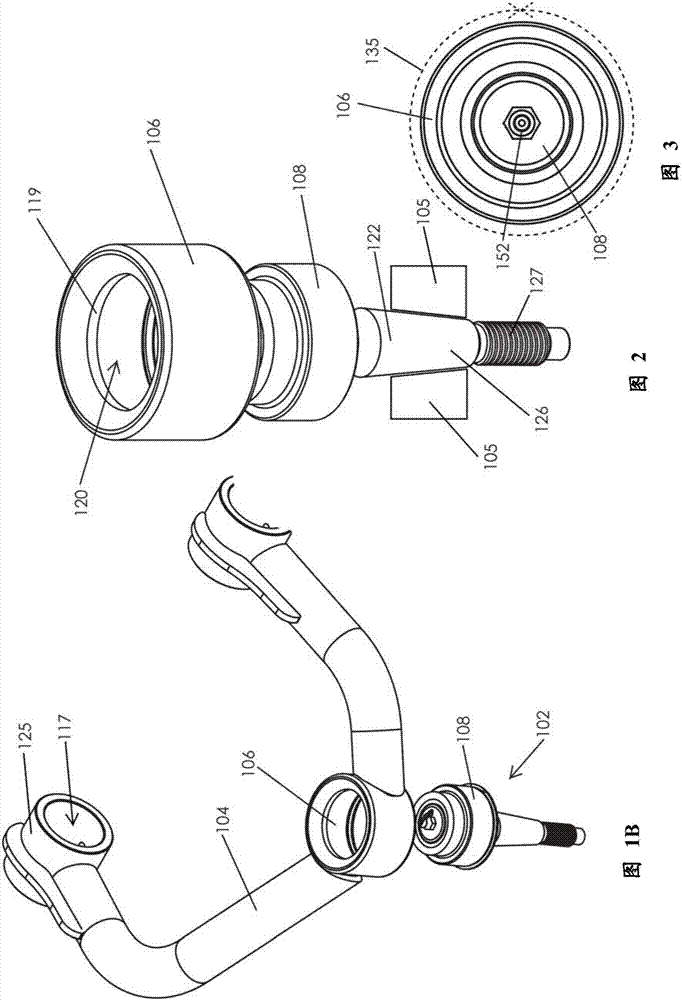

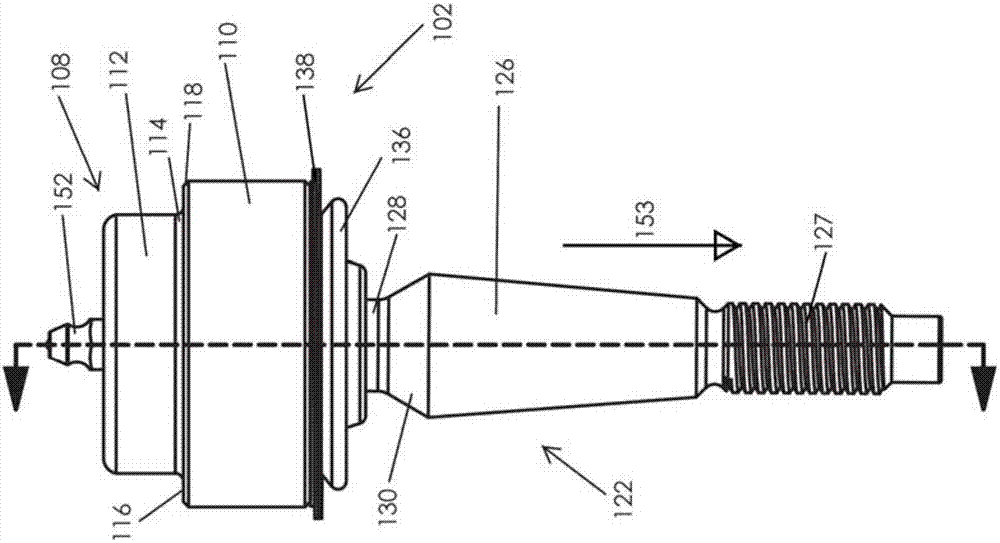

[0042] Specifically, embodiments disclosed herein relate to ball joints that allow for ease of maintenance and durability of components while providing high or wide angles / angularity of movement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com