Lift force device

A lift, large sprocket technology, used in helicopters, transportation and packaging, aircraft, etc., can solve problems such as unfavorable lift, failure, and difficulty in vertical lifting of flappers, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

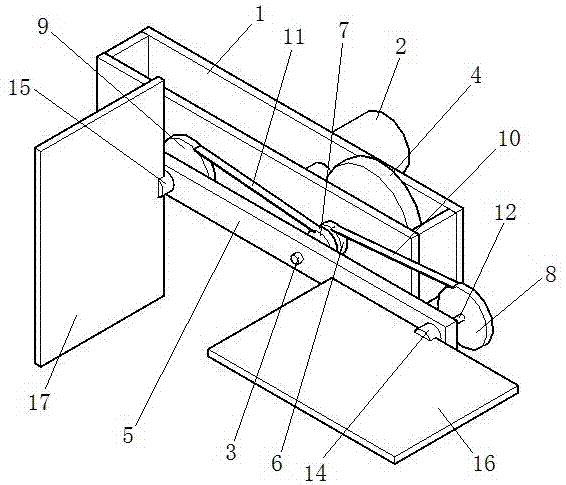

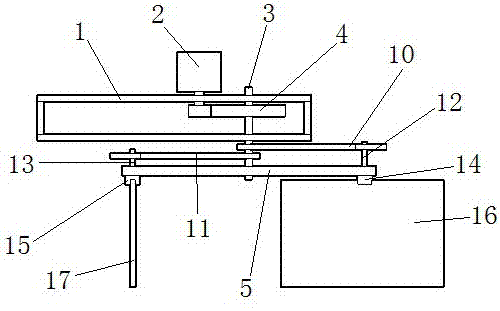

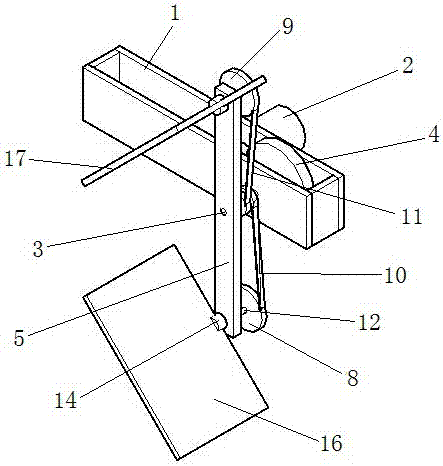

[0010] The present invention is now described in detail in conjunction with the accompanying drawings: a lift device, including a fixed frame 1, an engine 2, a main shaft 3, a large gear 4, a rotating arm 5, a first small sprocket 6, a second small sprocket 7, a first Large sprocket 8, second large sprocket 9, first chain 10, second chain 11, first traction shaft 12, second traction shaft 13, first fixing clip 14, second fixing clip 15, first blade 16 and the second blade 17. The main shaft 3 is installed on the fixed frame 1 through the bearing; the large gear 4 is installed on the main shaft 3; the middle part of the rotating arm 5 is fixed on the end of the main shaft 3; the power of the engine 2 is transmitted to the large gear 4 through the gear structure, and when the large gear 4 rotates The main shaft 3 drives the rotating arm 5 to rotate; the first small sprocket 6 and the second small sprocket 7 have the same structure; the first small sprocket 6 and the second small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com