Slanting friction wheel transmitter

A friction wheel and launcher technology, which is applied in the field of robots, can solve the problems of the friction wheel type launcher stuck and other problems, and achieve the effects of simple structure improvement, reliable principle and small speed loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

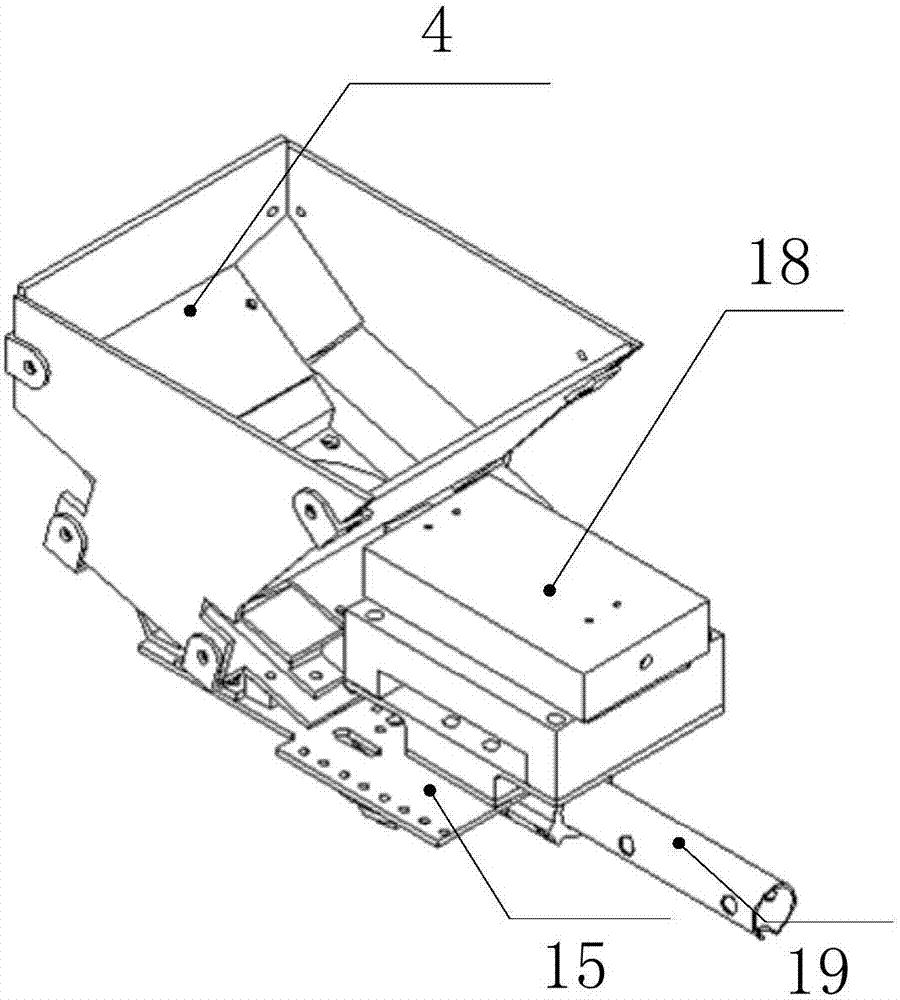

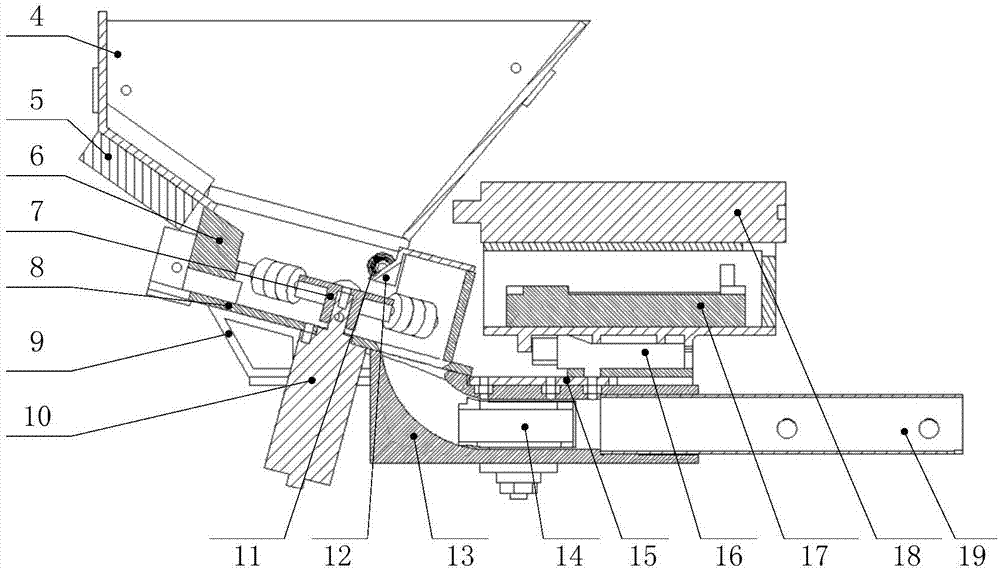

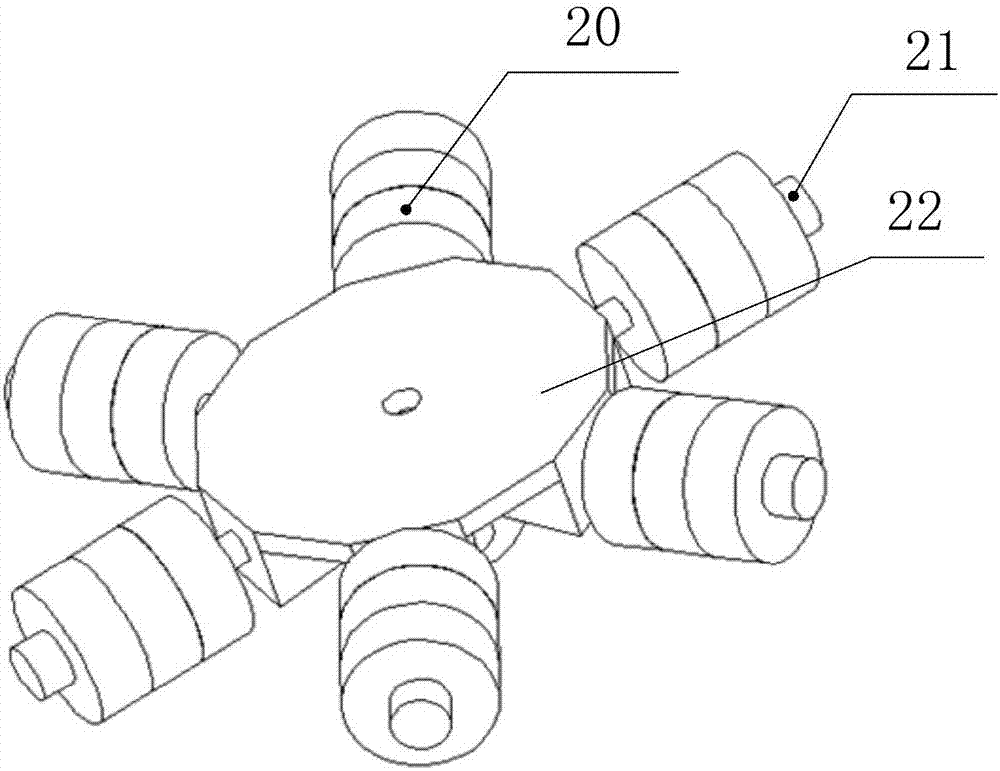

[0016] combine Figure 1 to Figure 5 , a kind of inclination friction wheel launcher of the present invention comprises a bomb bay 4, a flipping motor electric adjustment 5, a bomb bay seat 6, a dial 7, a bomb feeding base plate 8, a flipping motor 10, and a tower spring 11 , Isolation plate 12, L-shaped elbow 13, launch chassis 15, friction wheel ESC 16, launcher main control board 17, image transmitter 18, launch tube 19, two braces 9 and two friction wheels 14. The rear end of the launch chassis 15 is provided with an opening, and one end of the L-shaped elbow 13 protrudes upwards from the opening, and the other end is fixed on the bottom surface of the launch chassis 15 by bolts. A launch tube 19 is sheathed in the horizontal direction, and the launch tube 19 is fixedly connected with the L-shaped elbow 13 by bolts. Both sides of the L-shaped elbow 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com