Continuous preparation of 1,2-propanediamine catalyst and preparation method thereof

A technology of catalyst and propylenediamine, which is applied in the field of continuous preparation of 1,2-propylenediamine catalyst and its preparation, can solve the problems of difficult continuous production of the catalyst, low industrial application value, and short service life, and achieve significant industrial application value, Excellent catalyst activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention is implemented with reference to the following composition by weight percentage:

[0025] 10% Ni, 1.5% Ru, 1.5% Cs, 1.5% Ce, 10% alumina, and the rest is silicon oxide.

[0026] Preparation:

[0027] Make a solution of ethanol and 25% acidic silica sol at a volume ratio of 1:1; add nickel nitrate, ruthenium chloride, cesium nitrate and cerium nitrate to the mixture, add 5 mL of isopropanolamine, and dissolve completely; stand at room temperature 24h; remove the solvent under reduced pressure at 40°C; dry at 100°C for 10h; add alumina and graphite to the obtained solid powder, mix evenly, granulate and shape; roast at 500°C for 4h; The volume space velocity is 600h -1 Hydrogen reduction for 3h.

[0028] Catalytic Performance Evaluation:

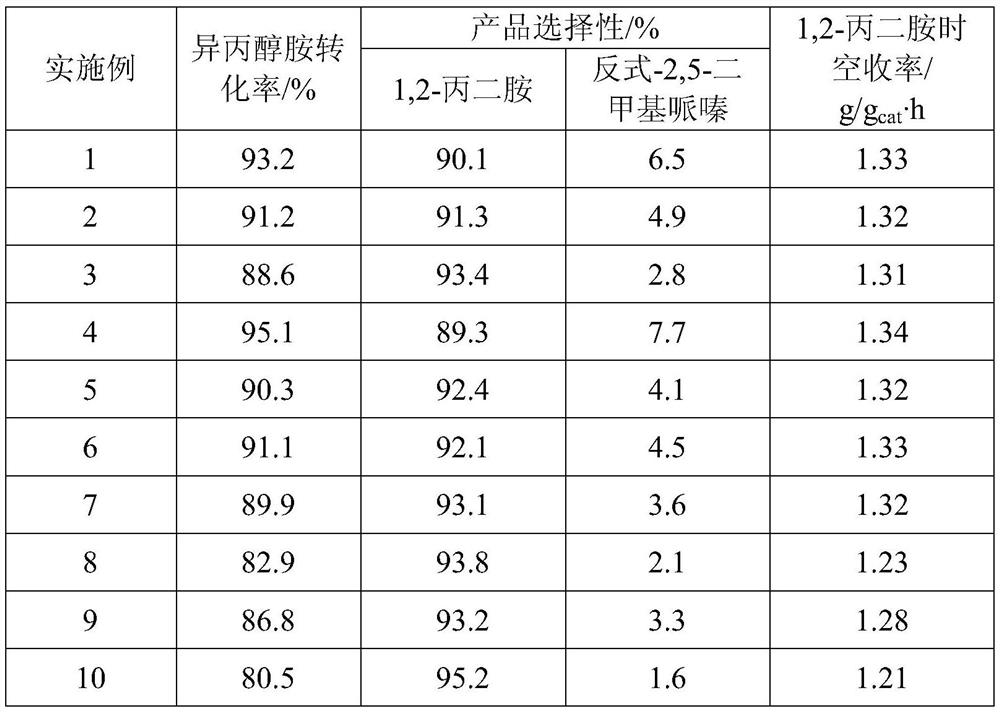

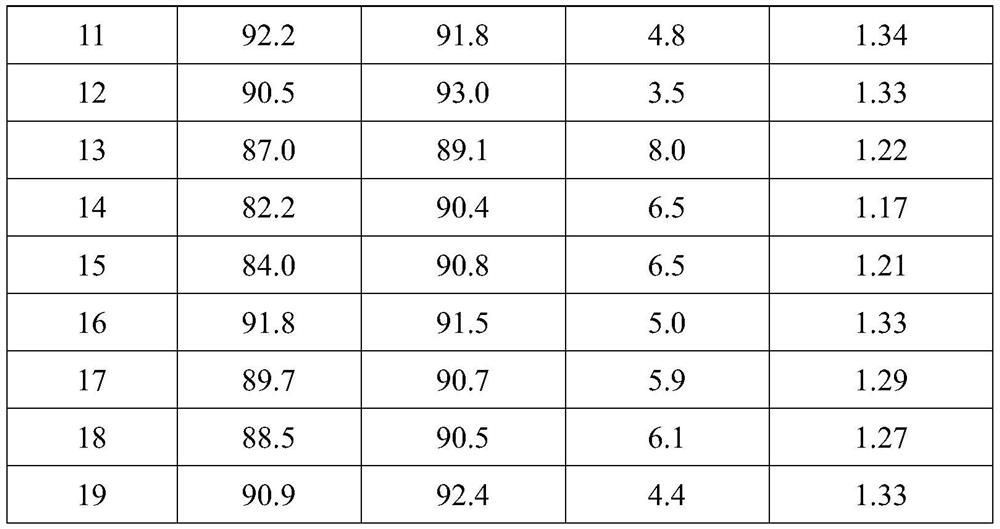

[0029] Cool naturally to a temperature of 160°C, at a pressure of 7 MPa, the molar ratio of hydrogen to isopropanolamine is 2:1, the molar ratio of raw material liquid ammonia to isopropanolamine is 12:1, and t...

Embodiment 2

[0031] The present invention is implemented with reference to the following composition by weight percentage:

[0032] 15% Ni, 0.5% Ru, 2.5% Cs, 0.5% La, 15% alumina, and the rest is silicon oxide.

[0033] Preparation:

[0034] Make a solution of methanol and 25% acidic silica sol at a volume ratio of 1:1; add nickel nitrate, ruthenium chloride, cesium nitrate and lanthanum nitrate into the mixture, add 5 mL of isopropanolamine, and dissolve completely; stand at room temperature 16h; remove the solvent under reduced pressure at 40°C; dry at 100°C for 10h; add alumina and graphite to the obtained solid powder, mix evenly, granulate and shape; roast at 500°C for 4h; The volume space velocity is 600h -1 Hydrogen reduction for 3h.

[0035] Catalyst performance evaluation conditions are the same as in Example 1, and the performance remains unchanged after running for 1000h. The results are shown in Table 1.

Embodiment 3

[0037] The present invention is implemented with reference to the following composition by weight percentage:

[0038] 5% Ni, 1.5% Ru, 0.5% Sr, 1.0% La, 8% alumina, and the rest is silicon oxide.

[0039] Preparation:

[0040] Make a solution of ethanol and 25% acidic silica sol at a volume ratio of 1:4; add nickel nitrate, ruthenium chloride, strontium nitrate and lanthanum nitrate to the mixture, add 6 mL of isopropanolamine, and dissolve completely; stand at room temperature 0.5h; remove solvent under reduced pressure at 40°C; dry at 100°C for 10h; add alumina and graphite to the obtained solid powder, mix evenly, granulate and shape; roast at 500°C for 4h; obtain catalyst precursor at 400°C under normal pressure, Take volumetric space velocity as 600h -1 Hydrogen reduction for 3h.

[0041] Catalyst performance evaluation conditions are the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com