Plasma cutting table

A plasma and cutting table technology, applied in plasma welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of low precision, low yield, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

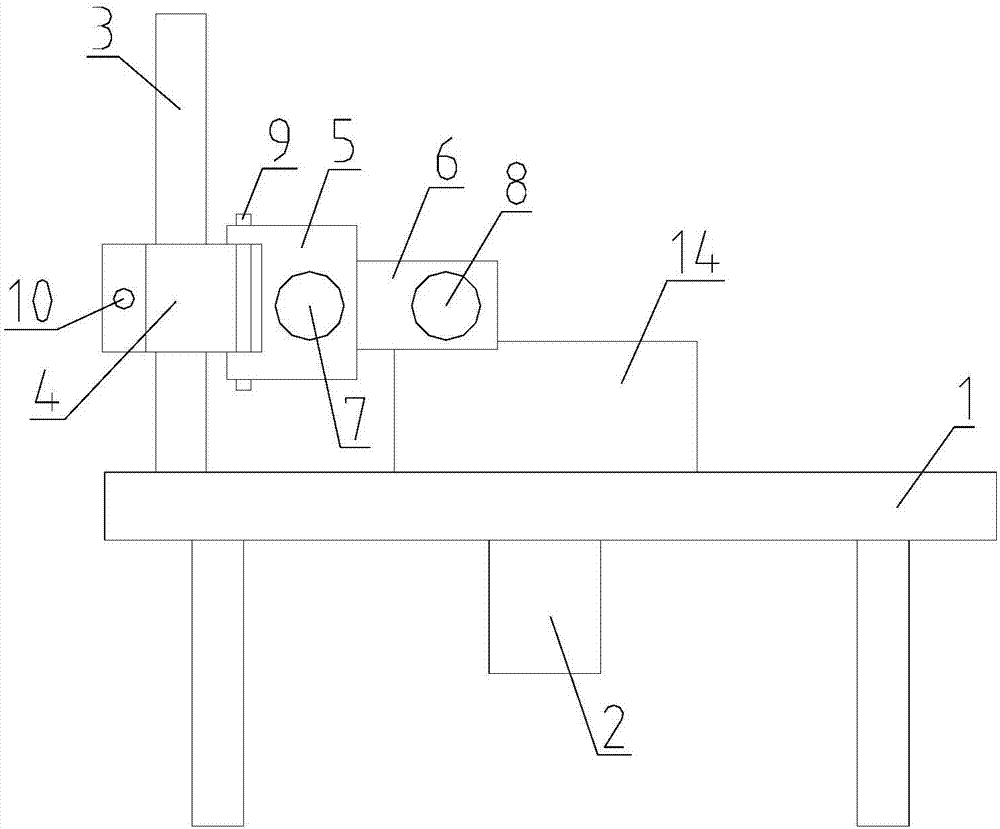

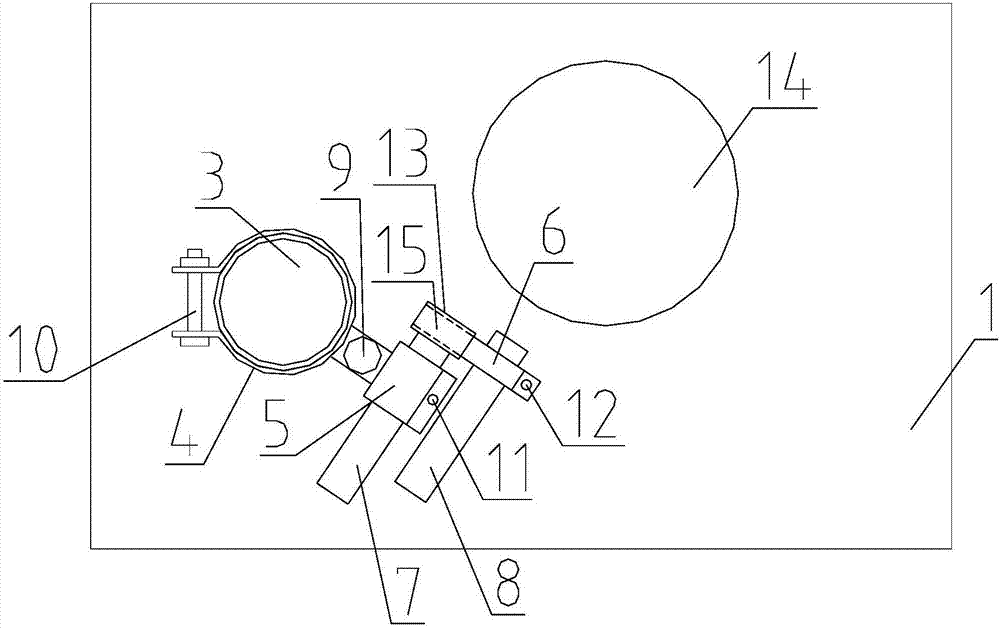

[0022] Such as figure 1 with 2 As shown, a plasma cutting table includes a frame 1, a column 3, a height adjustment block 4, an adjustment block one 5, an adjustment block two 6, an adjustment rod 7, and a plasma cutting gun 8. The lower part of the frame 1 is provided with a In the drive mechanism that drives the impeller 14 that is located at the top of the frame 1 to rotate, the column 3 is vertically arranged and its bottom end is fixedly connected to the top of the frame 1, and the height adjustment block 4 can be rotated around the The axis of the column 3 is rotated and positioned and can be moved and positioned in the vertical direction. The adjustment block 5 is rotatably connected with the height adjustme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap