Plastic electronic tray

An electronic tray and tray technology, applied in the electronic field, can solve the problems of low operating efficiency of electronic chips, inability to place both front and back sides and fast flipping, etc., so as to achieve the goal of not easy to scatter, reduce the vacuuming process, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

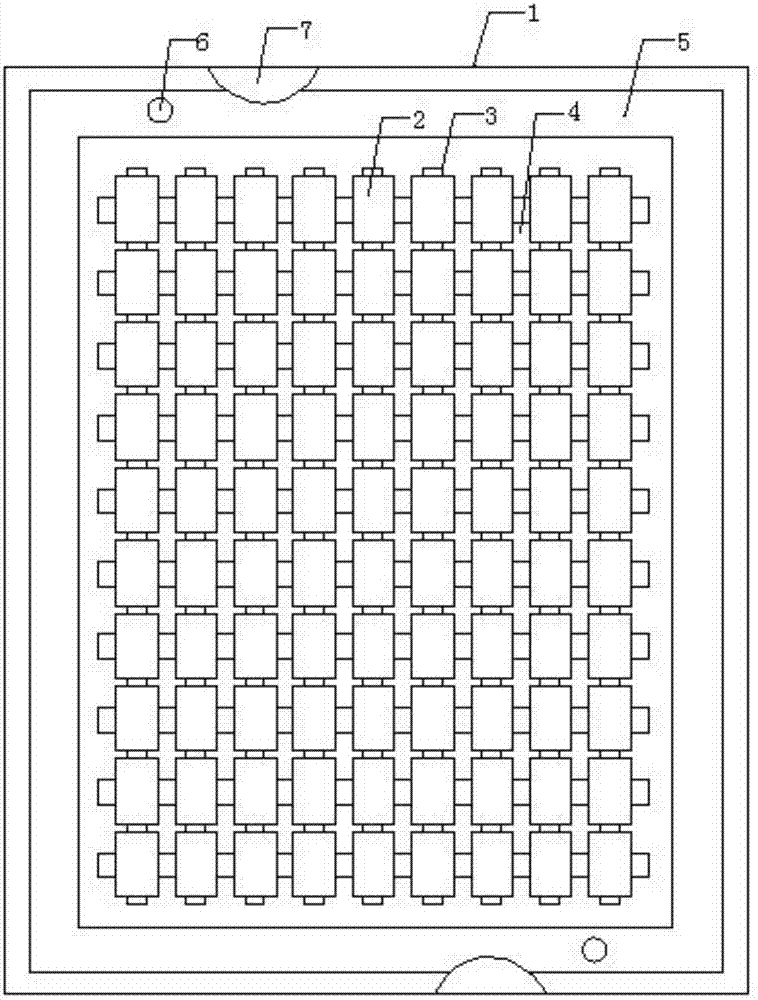

[0016] like figure 1 As shown, the present invention provides a plastic electronic tray, comprising a tray main body 1, the front of the tray main body 1 is divided into several evenly distributed electronic chip placement platforms 2 by several uniformly distributed forward protrusions 3, and the back side of the tray main body 1 A number of uniformly distributed electronic chip placement platforms 2 are separated by a number of evenly distributed reverse protrusions 4. The outer ring of the tray body 1 is provided with overlapping concave grooves 5, and the electronic chip placement platforms 2 on the front and back sides of the tray body 1 are one by one. Correspondingly, the positive protrusions 3 are evenly distributed on the four sides of the electronic chip placement platform 2, and the reverse protrusions 4 are evenly distributed on the four corners of the electronic chip placement platform 2. The bottom of the tray is provided with a threaded groove, and the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com