Angle servo adjustment mechanism for roller type straightening machine

A technology of roller straightening machine and adjustment mechanism, which is applied in the field of angle servo adjustment mechanism of roller straightening machine, which can solve the problems of hub wear, hub rotation, and impossibility of jacking hub, etc., and achieve load bearing and impact resistance powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

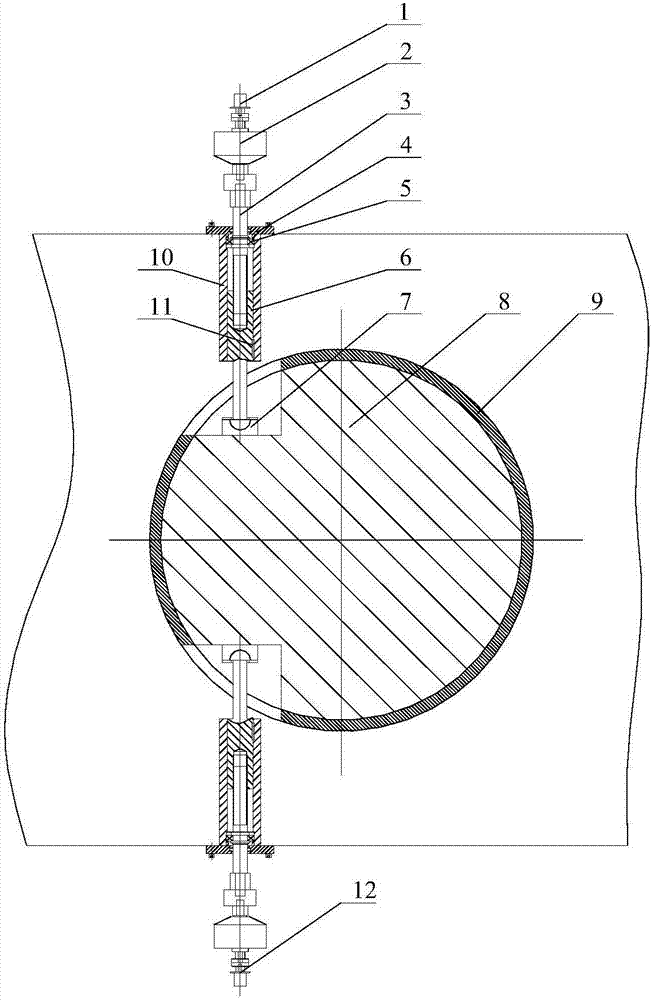

[0025] The servo motor 1 can control the number of rotations and torque through the encoder. When the servo motor 1 above drives the screw 3 to rotate, the screw 3 is axially fixed by the bearing 5. Since there is a gap between the nut 6 and the cylinder 10 The guide key 11 can only move forward and backward, so the nut 6 moves downward, and the head 7 at the front end of the nut 6 pushes the rotating hub 8 to realize the counterclockwise rotation of the rotating hub 8 . In the same way, the servo motor 2 12 below can also drive the lower mechanism to push the rotating hub 8 to rotate clockwise.

Embodiment 2

[0027] Because the servo motor 2 12 can realize the control of the screw rod stroke through the encoder, and at the same time, the servo motor 1 can realize the control of the torque, therefore, when the rotating hub 8 rotates counterclockwise, in order to accurately control the angle of rotation, the servo motor 12 below Firstly, the screw rod is driven to rotate, and the nut 6 and the top 7 are driven to move downward, and stop to the angle to be rotated through stroke control. Subsequently, the upper servo motor 1 also drives the screw mandrel 3 to rotate and drives the nut 6 to move downwards, so that the jacking hub 8 rotates counterclockwise. The servo motor 1 is controlled by the torque, and the jacking hub 8 rotates until it stops. until it moves (set the detent torque). Similarly, when the rotating hub 8 needs to adjust the angle clockwise, the upper servo motor 1 controls the stroke to drive the screw rod 3 to rotate and drive the nut 6 to move upward, and stops to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com