Automatic butting and posture-adjusting positioning device used for large cylindrical components and with coordinated motion function

An automatic docking and positioning device technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easy overturning and high pressure on cylindrical components, so as to prevent overturning, improve assembly efficiency and reduce force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

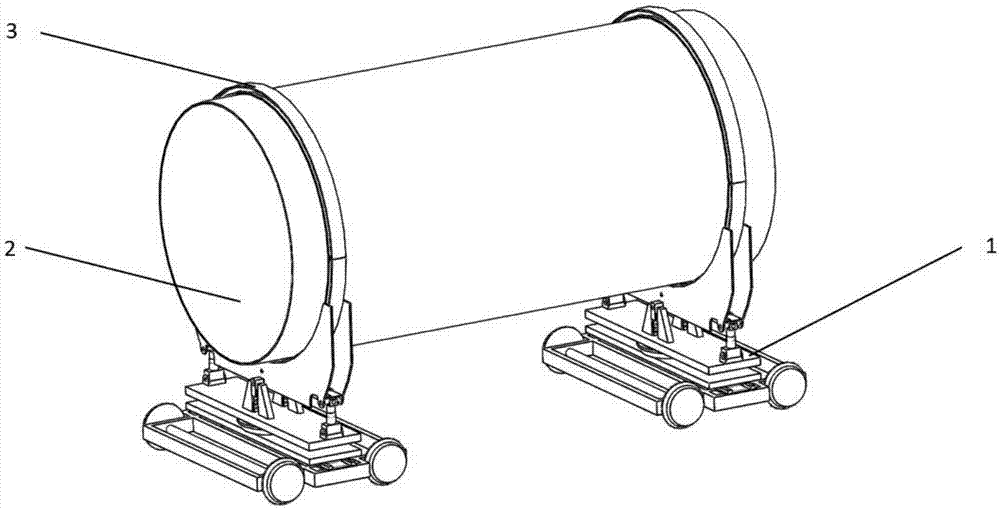

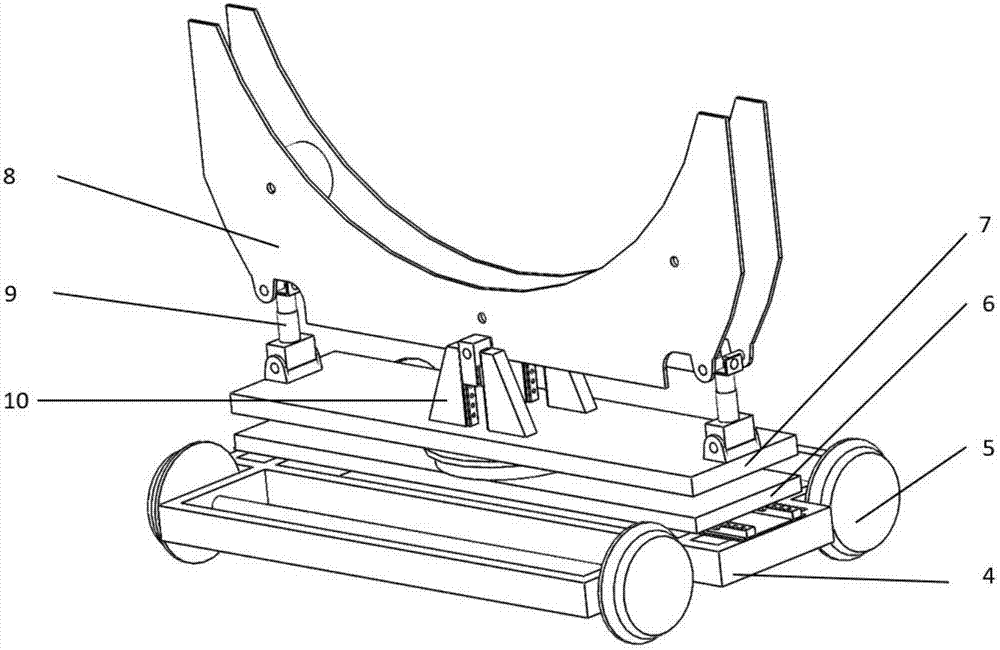

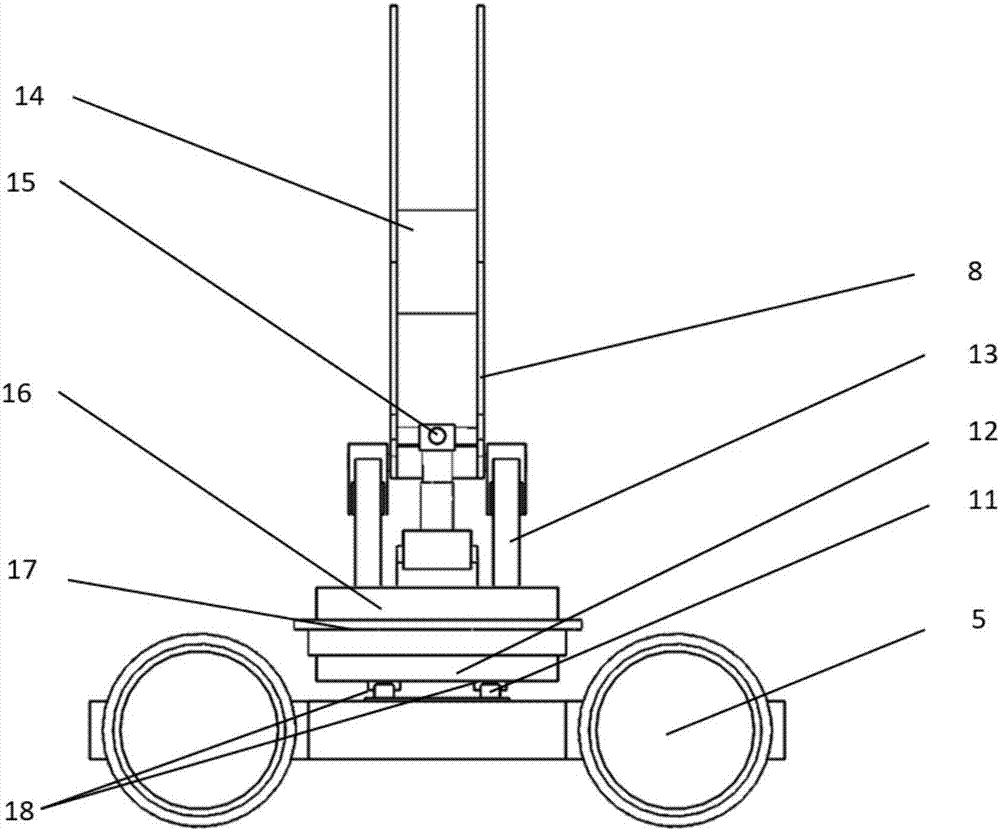

[0017] Such as figure 1 and figure 2 As shown, in this embodiment, two sets of positioning mechanisms 1 with toothed hoops 3 are fixedly connected with the cylindrical member 2 to be adjusted. The positioning mechanism 1 includes: a chassis 4, a track wheel pair 5, and a horizontal attitude adjustment platform. 6. Rotary attitude adjustment platform 7, bracket 8, vertical lifting platform 9 and limit device 10, wherein: the track wheel pair 5 on the chassis 4 can move in a large range along the x direction; the horizontal attitude adjustment platform 6 can move left and right along the guide rail Linear movement, with y-direction attitude adjustment function; the lower part of the rotating attitude adjustment platform 7 and the horizontal attitude adjustment platform 6 constitute a revolving pair around the z-axis; the vertical lifting platform 9 can move linearly along the vertical direction to realize the z-direction attitude adjustment function; The frame 8 realizes the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com