Use method of tool box for building site

A technology for construction sites and toolboxes, applied in the field of construction tools, can solve problems such as low work efficiency, detection of work impact, and disorderly placement of tools, and achieve the effects of saving manpower and time, facilitating movement and handling, and increasing storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

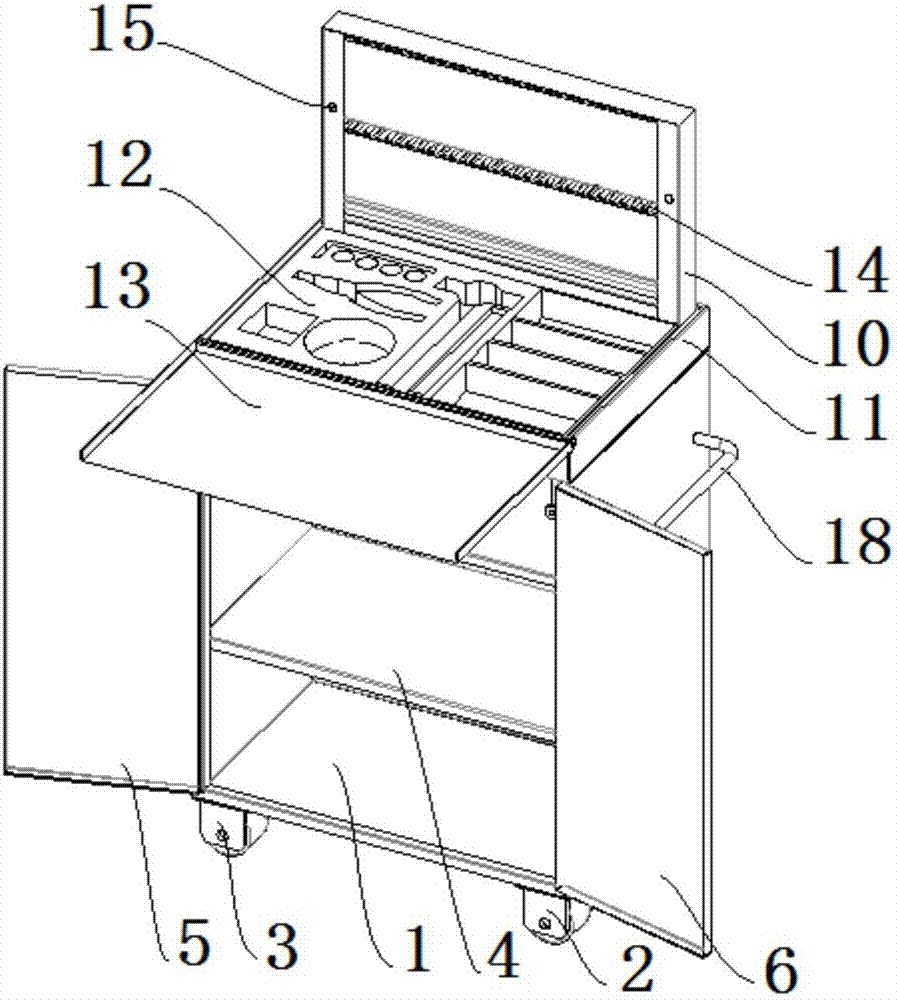

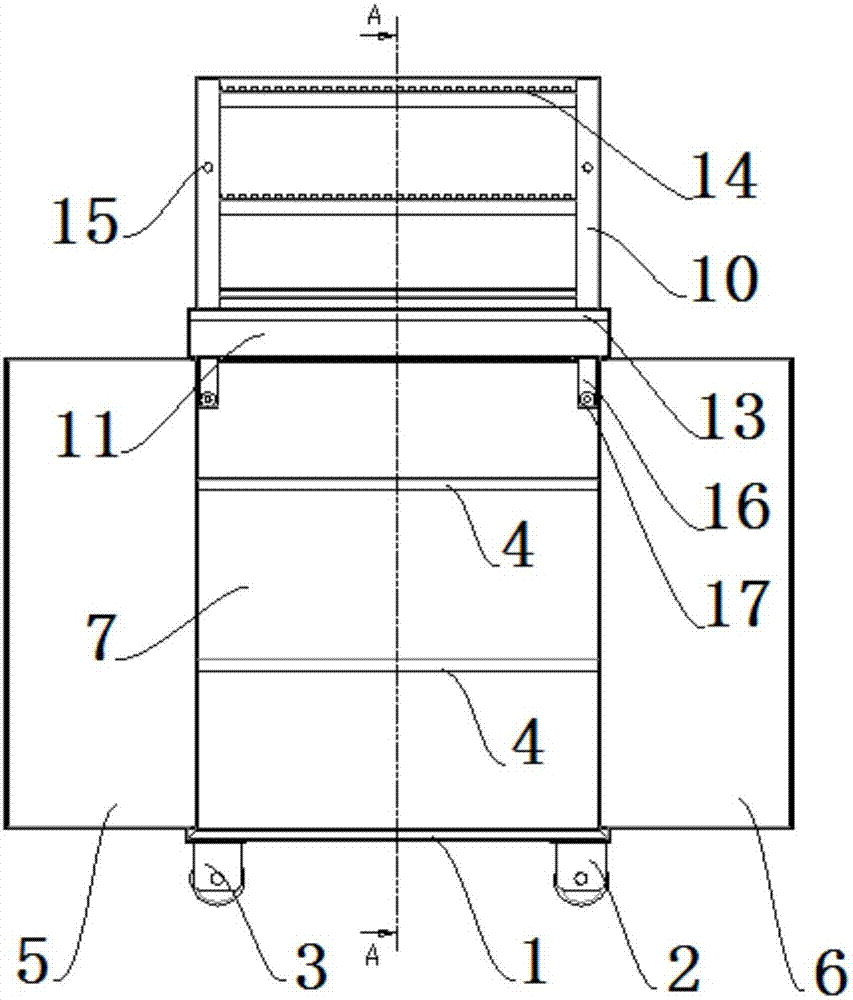

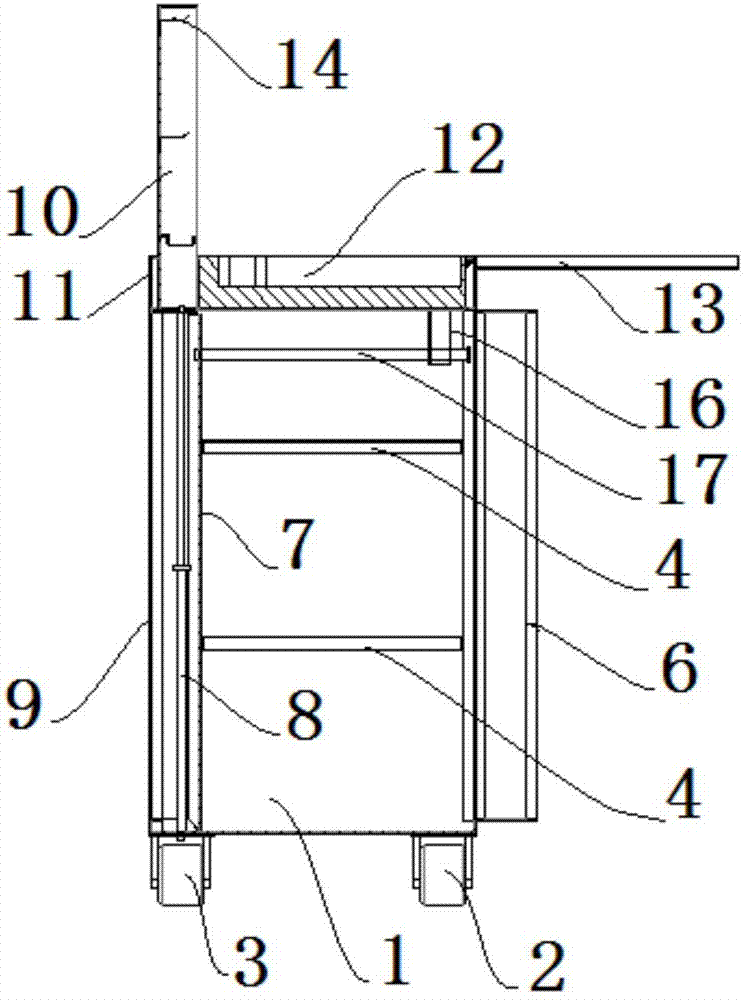

[0028] Such as Figure 1 to Figure 3 Shown, the using method of construction site toolbox of the present invention comprises the following steps:

[0029] Step 1, the worker closes the brake device of the universal caster 2 of the tool box body 1, pulls the handle 18 of the tool box by hand, and moves the tool box to the construction site of the construction site;

[0030] Step 2. Put the toolbox at the designated location on the construction site, and turn on the brake device of the universal caster 2 of the toolbox;

[0031] Step 3, the worker holds the key and opens the door lock 19 on the right door panel 6 of the toolbox, opens the right door panel 6, pulls out the latch on the inside of the left door panel 5, and opens the left door panel 5;

[0032] Step 4, the worker puts both hands into the tool box body 1 at the same time, holds the pull plate of the lock bar 17 with both hands and pulls it toward the worker's body side, the lock bar 17 starts to move in the lock ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com