Wear-resistant safety protection fence used for machine and provided with handle

A wear-resistant belt and protective fence technology, which is applied in engineering safety devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of poor stability of the protective fence, easy contact with the protective fence, and easy damage to the reducer. Achieve the effect of saving manpower and material resources, not easy to be damaged, and firmly connected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

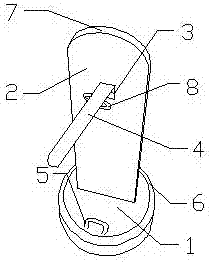

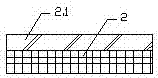

[0019] see figure 1 and figure 2 , the present invention is a machine with wear-resistant belt handle safety protection bar, which includes a base 1, a protection rod 2 and a connecting rod 4, the surface of the protection rod 2 is provided with a wear-resistant layer 2.1, the base 1 and the protection rod 2 Vertically connected and formed by welding, the protective rod 2 is provided with a through hole 3, the connecting rod 4 runs through the through hole 3, and the base 1 and both sides of the protective rod 2 are respectively provided with a handle 5. The upper edge of the base 1 is provided with a circular arc chamfer 6 , the top of the protective rod 2 is provided with a circular arc 7 , and the connecting rod 4 is covered with a protective sleeve 8 .

[0020] The handle 5 is convenient for workers to carry and move the safety protection bar of the machine with a wear-resistant belt handle; after the arc chamfer 6 is set, the worker will not be injured once he touches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com