Stamping die transporting trolley used in factory

A technology of stamping dies and handling trolleys, which is applied to forming tools, manufacturing tools, trolleys, etc., can solve the problems of low handling efficiency, waste of time, and affecting handling efficiency, and achieve the goals of saving unloading time, convenient use, and improving handling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

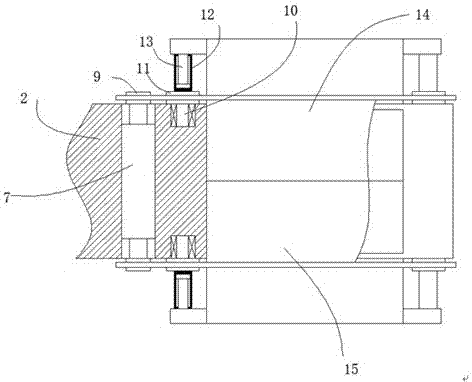

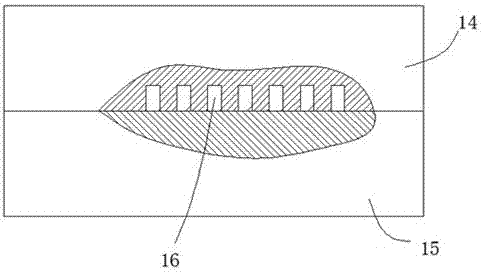

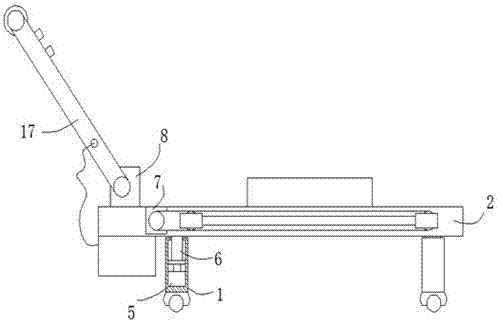

[0017] refer to Figure 1-3 , a stamping die handling trolley for factories, including a guide sleeve 1, a hydraulic cylinder 5 is fixed on the inside of the guide sleeve 1, and the piston rod of the hydraulic cylinder 5 is fixed with a support rod 6 slidingly sleeved on the inside of the guide sleeve 1, and the support rod 6 The end away from the hydraulic cylinder 5 is fixed with the stage 2 above the top of the guide sleeve 1, and the top of the stage 2 is provided with a placement groove, and the top of the stage 2 is embedded with a double-head motor 7, and the double Both output shafts of the head motor 7 are fixed with first pulleys 9, and the first pulleys 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com