Hard alloy powder drying and rubbing integrated device

A cemented carbide and alloy powder technology, applied in the field of alloy powder processing, can solve the problems of air pollution, failure to meet environmental protection requirements, and difficulty in promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

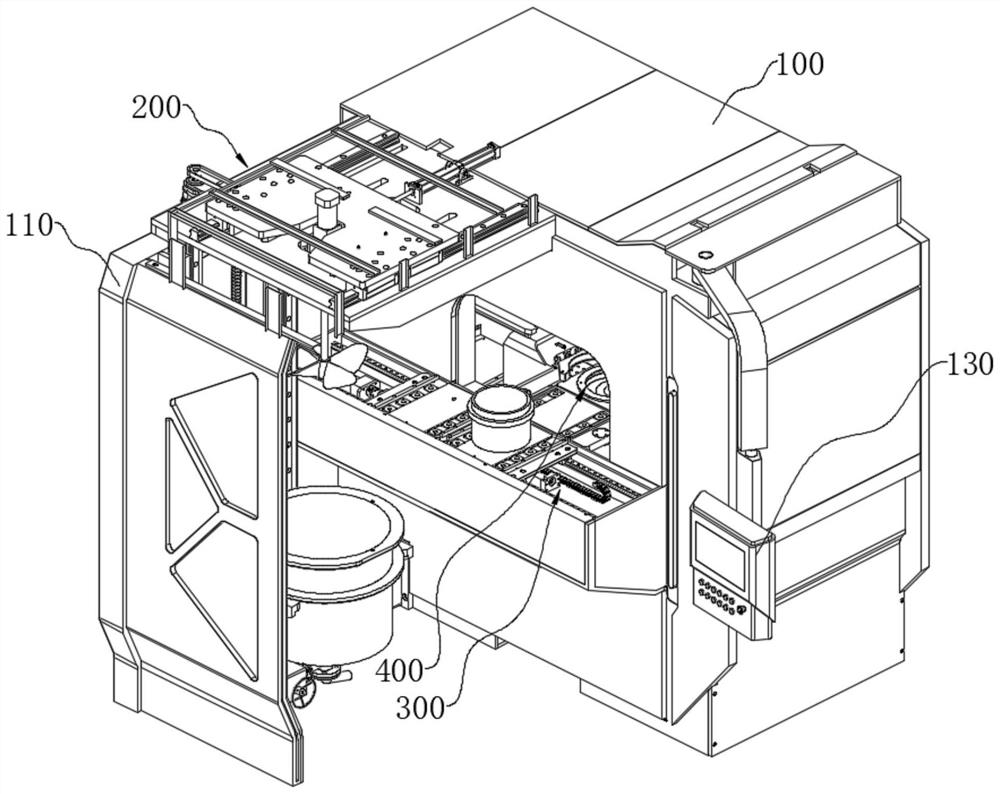

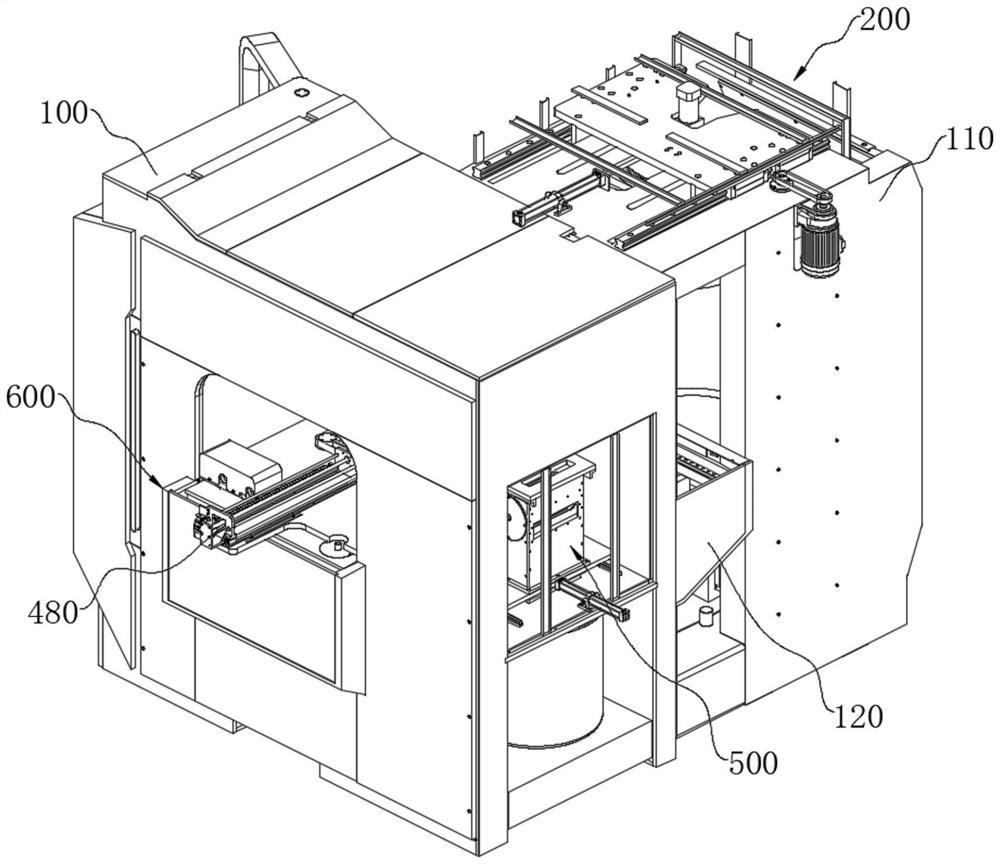

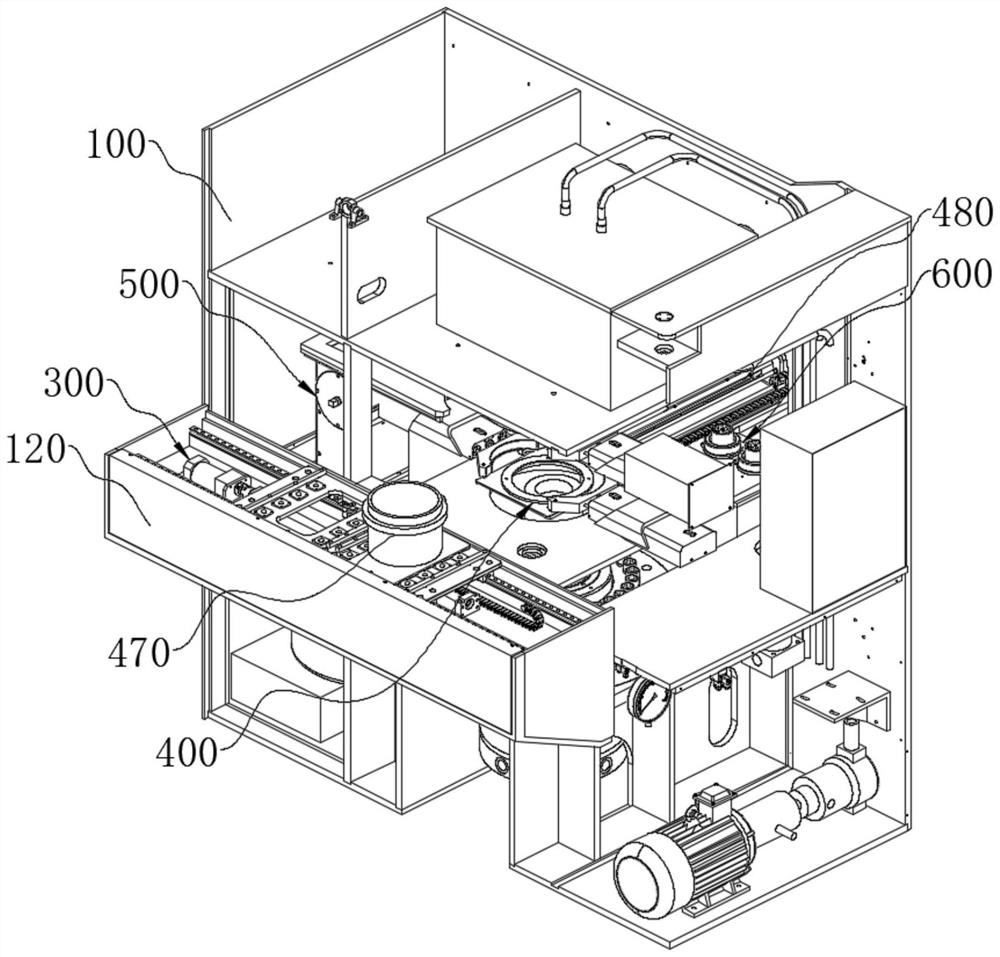

[0040] see Figure 1-Figure 11 As shown in the figure, the present invention provides an integrated device for drying and grinding cemented carbide powder, including a frame 100 and a side plate frame 110 installed on the front side of the frame 100, a workbench 120 arranged in the middle layer in front of the frame 100, and a PLC operation screen. 130. The middle of the frame 100 is provided with a cold pressing and drying system 400 for clamping and extruding the alloy powder and draining the moisture. A sliding platform system 300 for transporting the alloy powder is installed on the top surface of the workbench 120. The cold pressing and drying system 400 includes a The main oil cylinder 430 below the A pair of positioning cylinders 450 for clamping the working cylinder 470 and a suction cylinder 480 for pushing and sucking the working cylinder 470, wherein hydraulic oil is stored in the oil supply table 411, and an oil pump is installed at the bottom, and the main oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com