Ironing machine for garment production

A technology for ironing machine and clothing, applied in the field of clothing processing, can solve the problems of easily scalded clothes, ironed clothes, hidden safety hazards, etc., and achieves the effects of avoiding scalding of clothes, preventing scalding of clothes, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Unless otherwise stated, the terms used herein have meanings commonly understood by those skilled in the art.

[0026] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

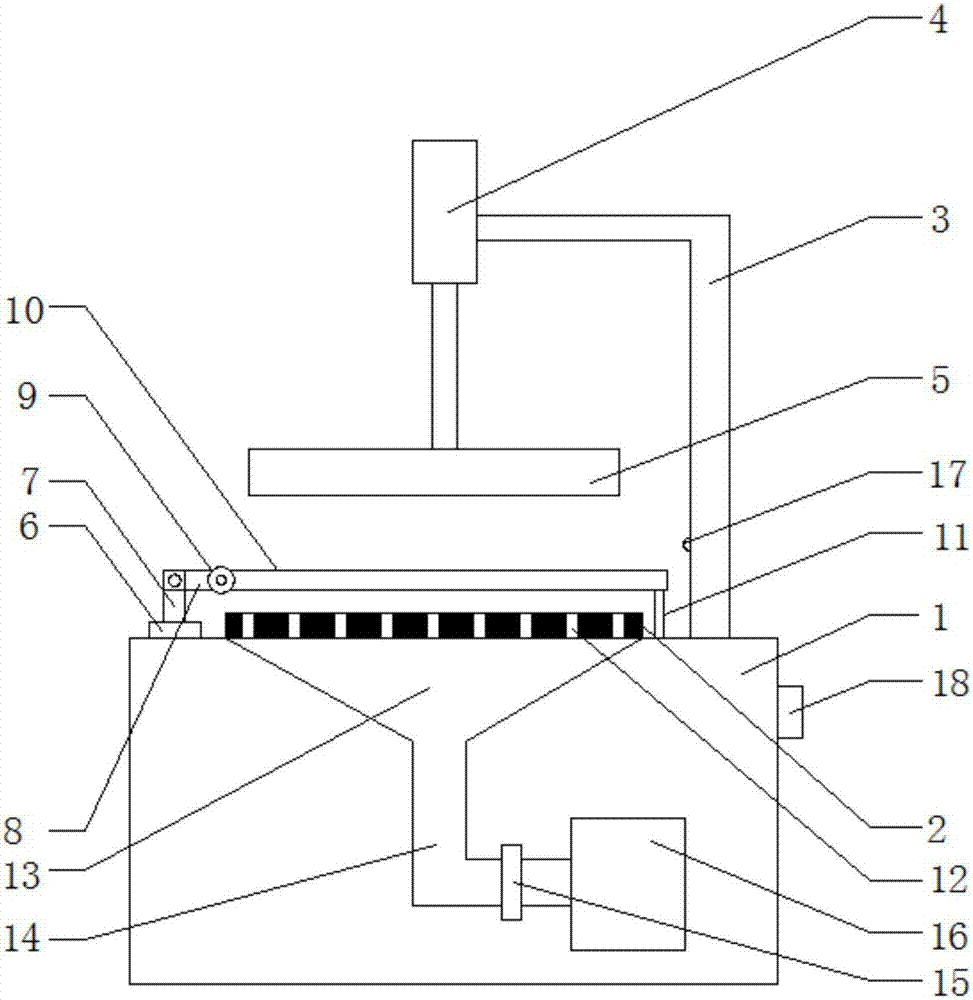

[0027] An ironing machine for garment production, characterized in that it includes a working table 1, an ironing table 2, a support frame 3, a cylinder 4, a pressure plate 5, a slide rail 6, a vertical rod 7, a rotating rod 8, and a universal connector 9 , Shelving board 10, support column 11, gas collection box 13, delivery pipeline 14, steam generator 16;

[0028] The inside of the workbench 1 is provided with a steam generator 16, a delivery pipeline 14 and a gas collection box 13, one end of the delivery pipeline 14 is connected with the steam generator 16, and the other end is connected with the gas collection box 13, and the gas collection The upper part of the box 13 is open, and the open end is fixedly connected to the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com