Climbing device for hot-line work

A live working and bearing technology, applied in ladders, buildings, building structures, etc., can solve the problems of lack of fixed structure, difficult hanging process, pitching and swinging of the ladder head, etc., and achieve the effect of convenient use and convenient work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

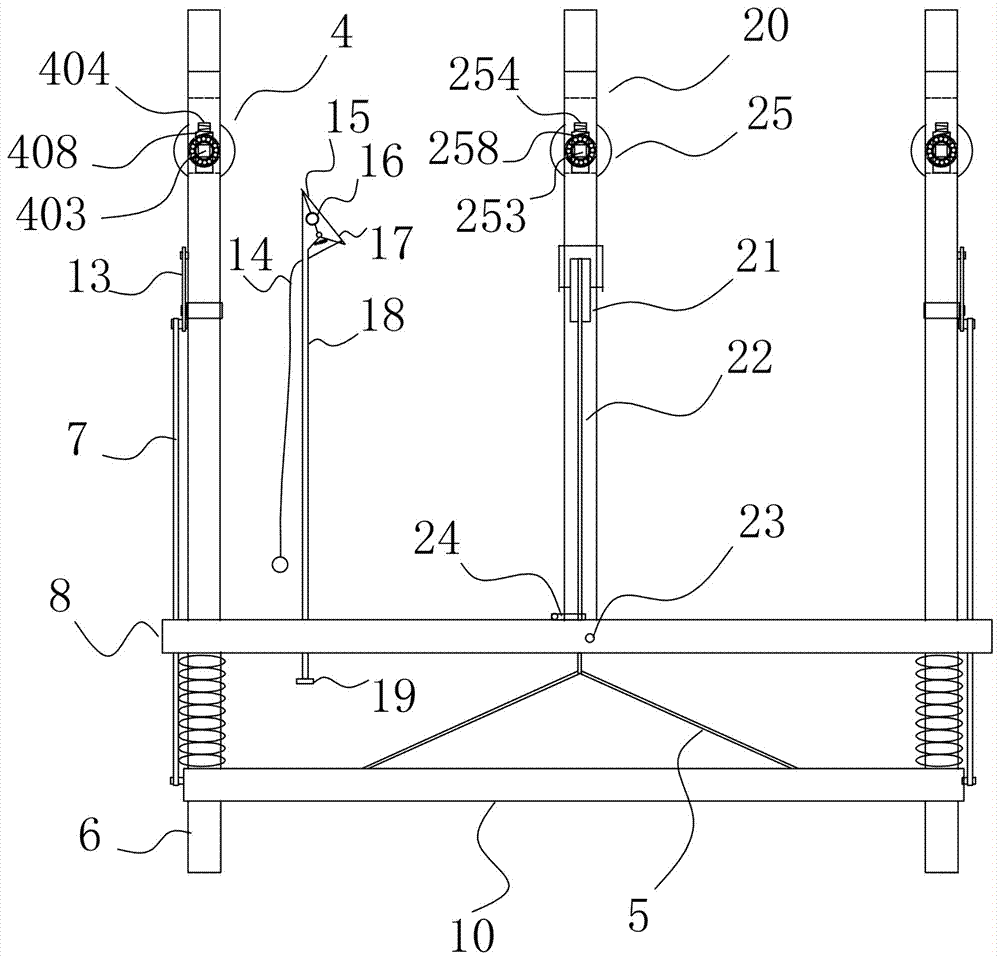

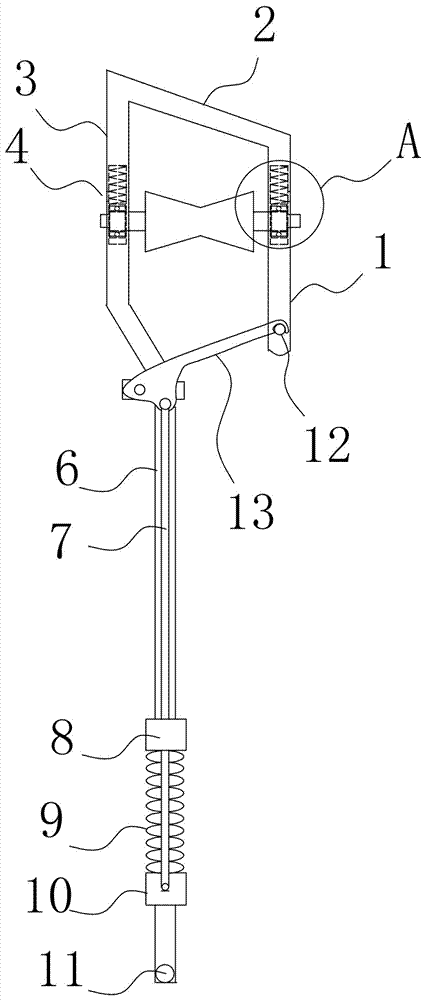

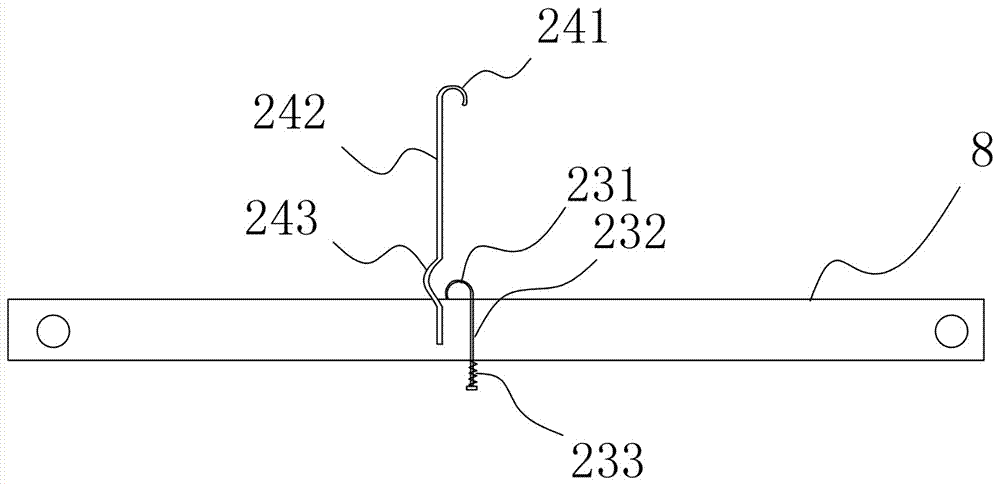

[0031] Examples of climbing devices for live working, such as Figure 1-6As shown, it includes two pulley brackets, a first cross bar 8, a second cross bar 10, a pulley hook 20 and a stay rope 22, and the pulley bracket includes a front bar 1, a rear bar 3, a diagonal bar 2 connecting the front bar and the rear bar , the support rod 6 and the first pulley mechanism 4, the lower end of the rear rod 3 is inwardly inclined and connected with the support rod 6, the first pulley mechanism includes a cable pulley 401 between the front rod 1 and the rear rod 3, and is located on the cable pulley The first bearing 407 on the wheel shaft 402 and the first bearing installation structure, the bottom of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com