Car gear shifting handle and production technology

A technology for shifting gears and handles for automobiles, applied in transmission control, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to open or close the locking device normally, unscientific quality inspection, unreasonable structure, etc. Meets ergonomic requirements, improves stability and comfort, and results in a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

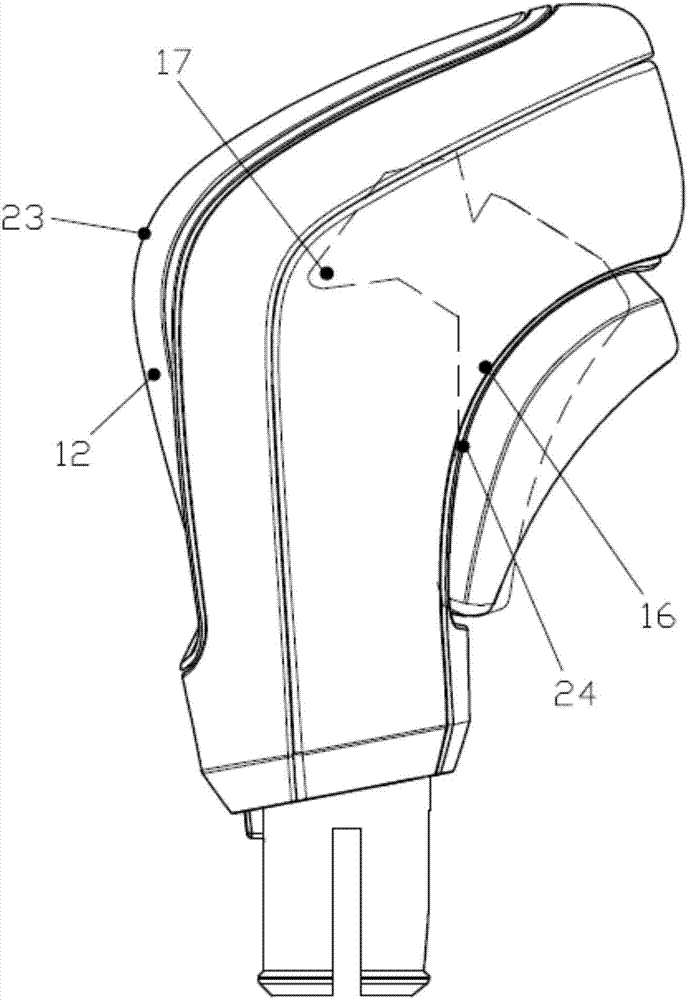

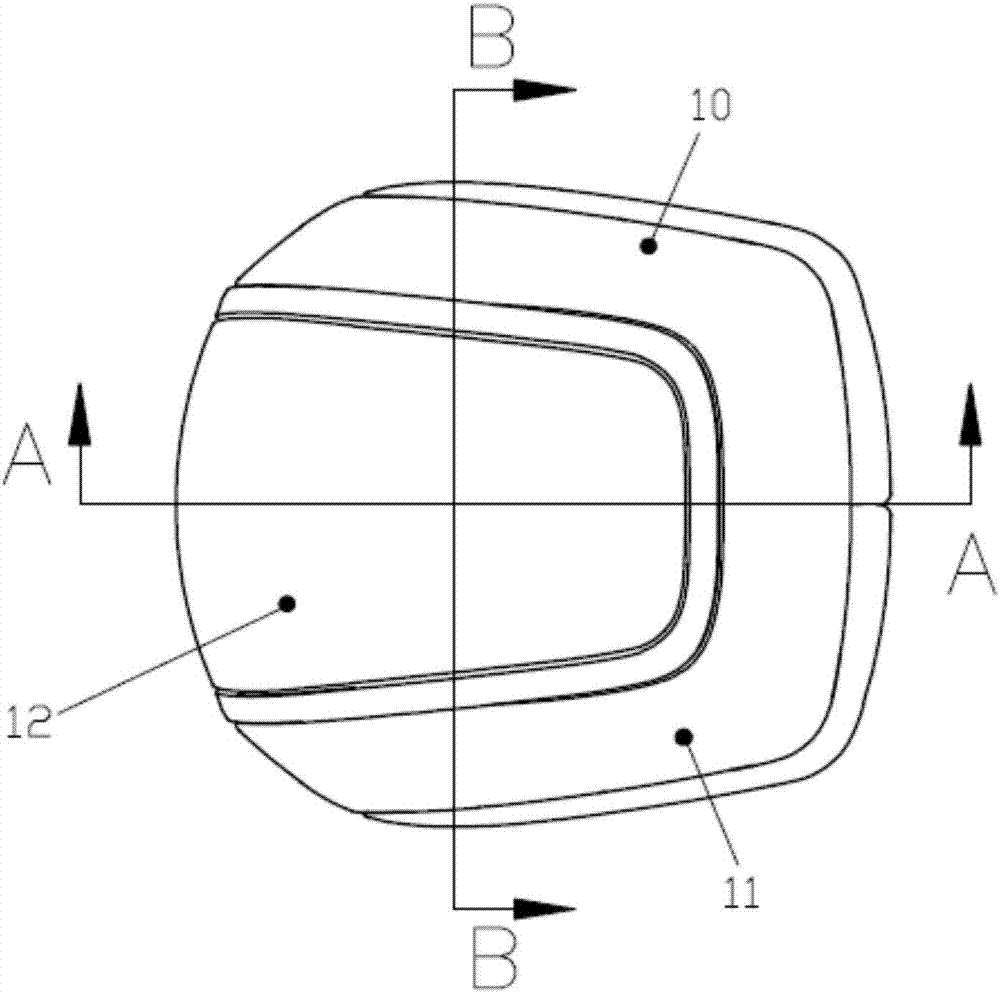

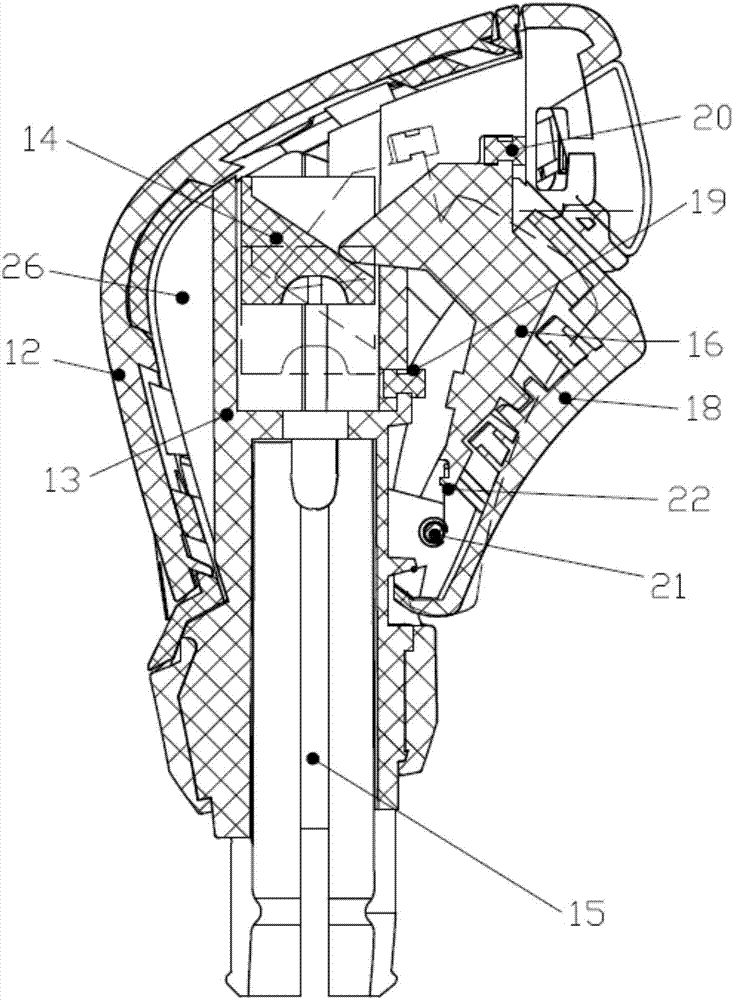

[0020] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4: A kind of automobile shift handle, comprises left body support 10 and right body support 11, is provided with inner core 13 in the cavity 26 that both are combined to form, and is all set on described left body support 10 and right body support 11 There is leather 25, which can protect the left body support 10 and the right body support 11, and enhance the tactile feeling of the hand simultaneously, and improve the comfort of shifting gears. Described inner core 13 is hollow, and its end is provided with the slide block 14 that slides up and down, is provided with connecting rod 15 below slide block 14, and slide block 14 and connecting rod 15 are all positioned in the hollow chamber of inner core 13, and slide block 14 Drive the connecting rod 15 to move up and down to complete the opening and closing of the locking device in the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com