Refrigerator box body inner container structure

A refrigerator liner and cabinet technology, applied to lighting and heating equipment, coolers, household appliances, etc., can solve the problems of high processing cost, end plate falling off, and more labor, so as to reduce installation costs and quickly install , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

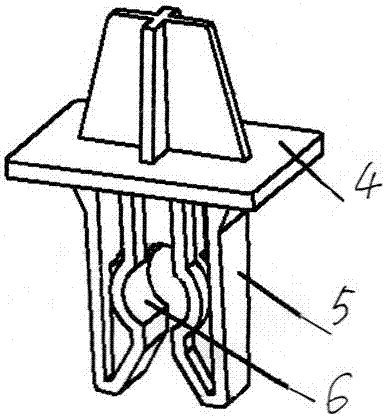

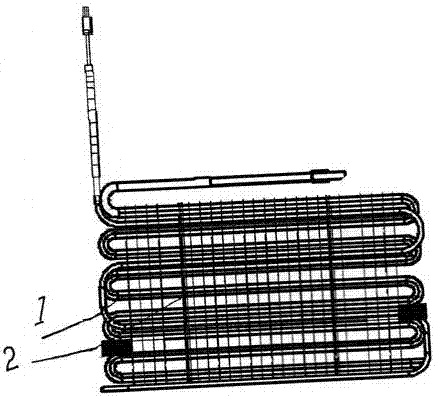

[0008] The embodiments are described in detail in conjunction with the above drawings, such as Figure 4 As shown, two square holes are processed on the refrigerator liner 2. The square holes are equipped with a support frame and fixed by bonding. The two semi-circular arcs on the locking end face of the support frame are sandwiched with fin evaporator pipes. A heating wire is installed on the fin evaporator, which is fixed in the arc groove on the surface of the fin by a steel wire clip, and the heating wire at the bottom of the evaporator is introduced into the bottom of the water receiving groove and fixed by aluminum foil tape.

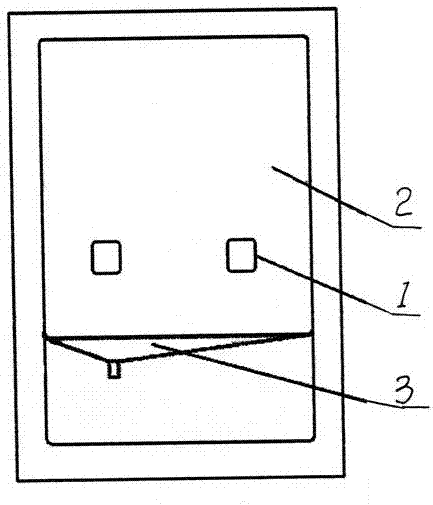

[0009] Two square holes 1 are processed on the inner liner of the refrigerator, (such as figure 1 Shown) The two square holes are parallel and symmetrical and have the same size. The diameter of the square holes can be determined according to the size of the fin evaporator. The bottom of the refrigerator liner is provided with a water receiving groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap