Storage tank with stirring device of spray gun

A technology of stirring device and spray gun, applied in the directions of spray device, transportation and packaging, dissolving, etc., can solve the problems of not mentioning, the paint cannot be sprayed, etc., and achieve the effect of avoiding paint layering, preventing paint layering, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

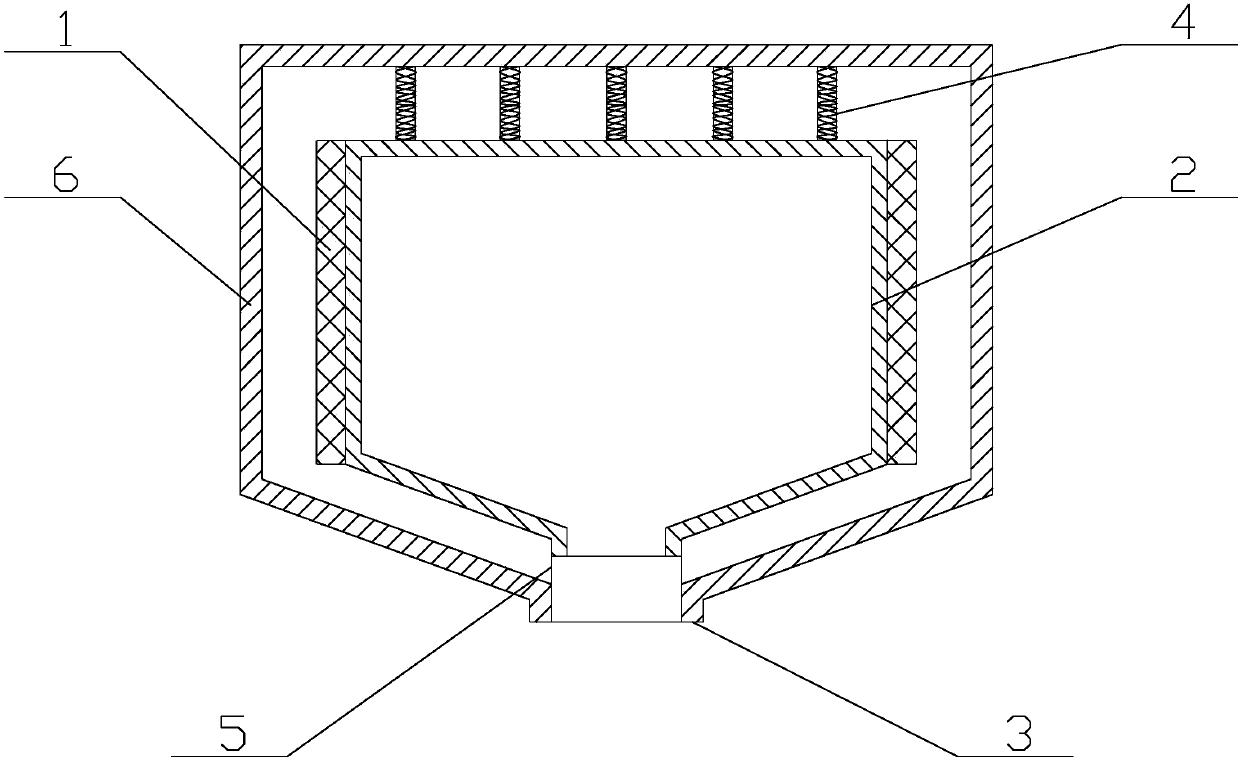

[0014] The present invention as figure 1 As shown, a spray gun storage tank with a stirring device, the spray gun storage tank is installed on the spray gun feed port, including an outer tank 1 and an inner tank 2, the outer tank 1 is provided with a discharge port 3, and the coating Stored in the inner tank 2, a stirring device is arranged between the outer tank 1 and the inner tank 2, and the stirring device is fixed on the top of the outer tank; the stirring device includes several groups of different lengths in the original state One end of the spring 4 is connected to the top of the inner tank 2, and the other end of the spring 4 is fixed on the top of the outer tank 1; the paint outlet of the inner tank 2 communicates with the discharge port 3. During the spraying process, the spray gun will vibrate. The vibration of the spray gun is used as the original power source, and the stirring device installed on the outer tank is used to amplify the vibration, so as to drive the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap