A blowing air distribution device for twin-roll thin strip continuous casting

A twin-roll thin strip continuous casting and gas cloth technology, applied in the field of iron and steel metallurgy, can solve the problems of adding additional transportation links of equipment, increasing installation difficulty of intermediate transition packages, increasing liquid level fluctuations, etc., so as to reduce the amount of tapping and molten steel. The effect of flow rate, improved stability and strip quality, and increased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

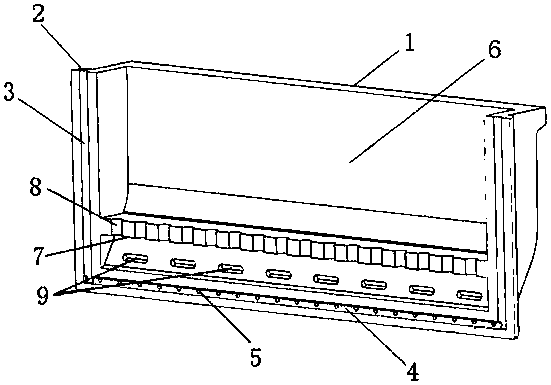

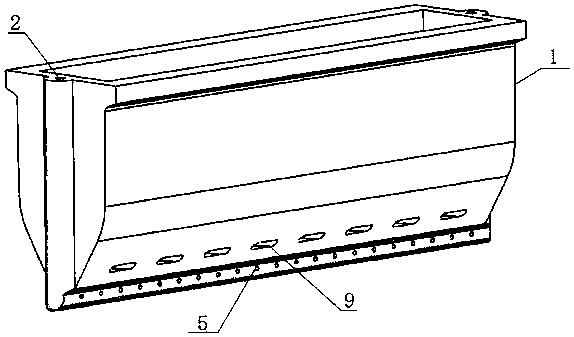

[0057] The casting speed of the thin strip is 35m / min, and the distance between the distributor and the gap of the crystallization roller is 35mm.

[0058] The main structural parameters of the blowing air distribution device for twin-roll thin strip continuous casting of the present invention are as follows:

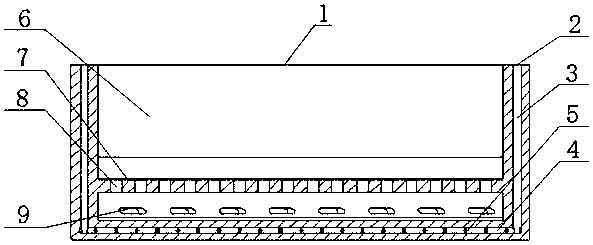

[0059] The distance between the molten steel separator 7 and the molten steel spit hole group 9 is 50mm, and the molten steel separator is provided with 10 circular molten steel falling holes with a diameter of 30mm;

[0060] The number of spit holes in the molten steel spit hole group 9 is 3, and the distance from the bottom of the distributor body 1 is 50mm;

[0061] The number of air outlet holes in air outlet group 5 is 20, and the distance from the bottom of the distributor body is 30 mm.

Embodiment 2

[0063] The casting speed of the thin strip is 60m / min, and the distance between the flow distributor and the gap of the crystallization roller is 68mm.

[0064] The main structural parameters of the blowing air distribution device for twin-roll thin strip continuous casting of the present invention are as follows:

[0065] The distance between the molten steel separator 7 and the molten steel spit hole group 9 is 60 mm, and the molten steel separator is provided with 12 circular molten steel falling holes with a diameter of 25 mm;

[0066] The number of spit holes in the molten steel spit hole group 9 is 2, and the distance from the bottom of the distributor body 1 is 50mm;

[0067] The air outlet hole group 5 has 15 air outlet holes, and the distance from the bottom end of the distributor body is 25mm.

Embodiment 3

[0069] The casting speed of the thin strip is 90m / min, and the distance between the distributor and the gap of the crystallization roller is 77mm.

[0070] The main structural parameters of the blowing air distribution device for twin-roll thin strip continuous casting of the present invention are as follows:

[0071] The distance between the molten steel separator 7 and the molten steel spit hole group 9 is 45mm, and the molten steel separator is provided with 15 circular molten steel falling holes with a diameter of 20mm;

[0072] The number of spit holes in the molten steel spit hole group 9 is 4, and the distance from the bottom of the distributor body 1 is 55mm;

[0073] The number of air outlet holes in the air outlet group 5 is 13, and the distance from the bottom end of the distributor body is 20mm.

[0074] In the air blowing flow distribution device for twin-roll thin strip continuous casting of the present invention, the addition of the molten steel partition insid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com