Bottom side beam, container and combining and assembling method and transportation method thereof

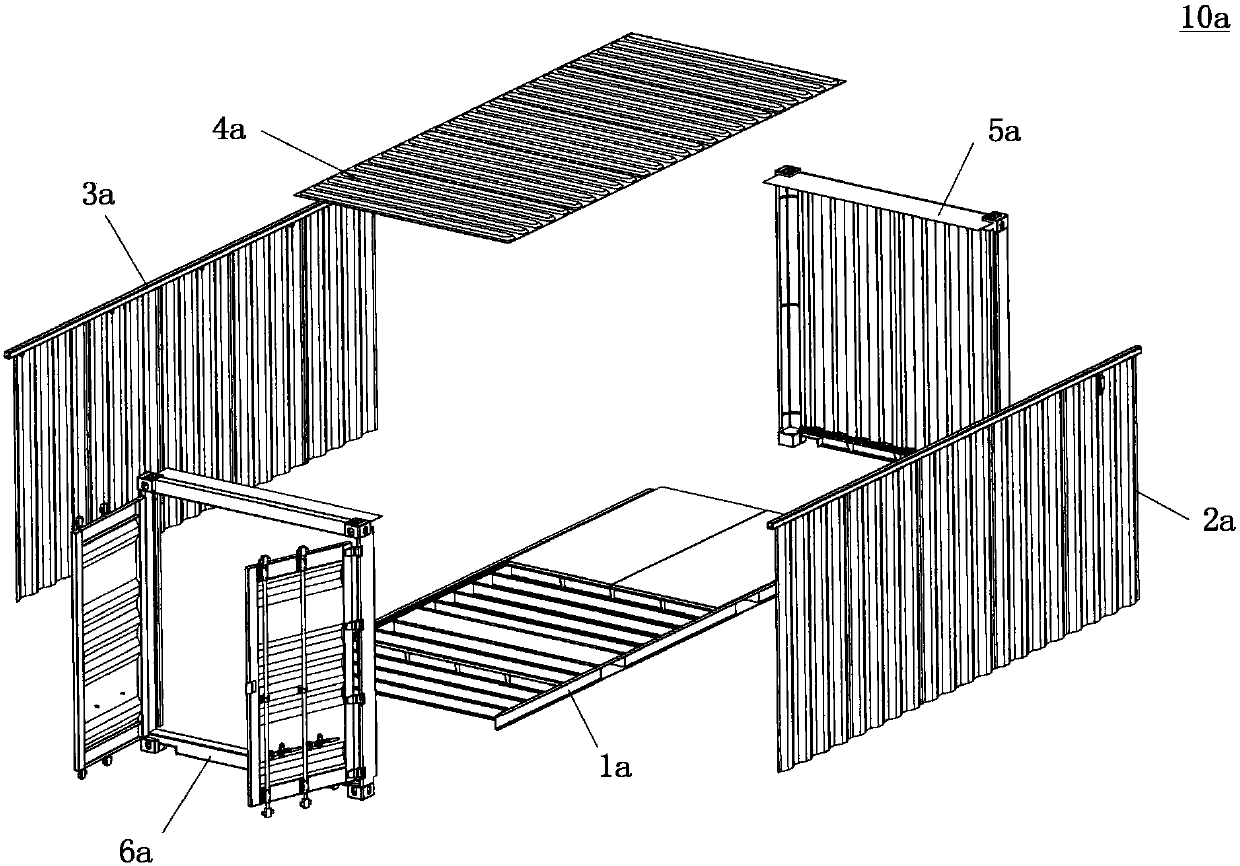

A technology of bottom side beams and containers, applied in the field of containers, can solve the problems of a large number of welding, the protruding part of the front wall assembly 5a, the door end assembly 6a, unfavorable packaging and transportation, etc., and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of this specification.

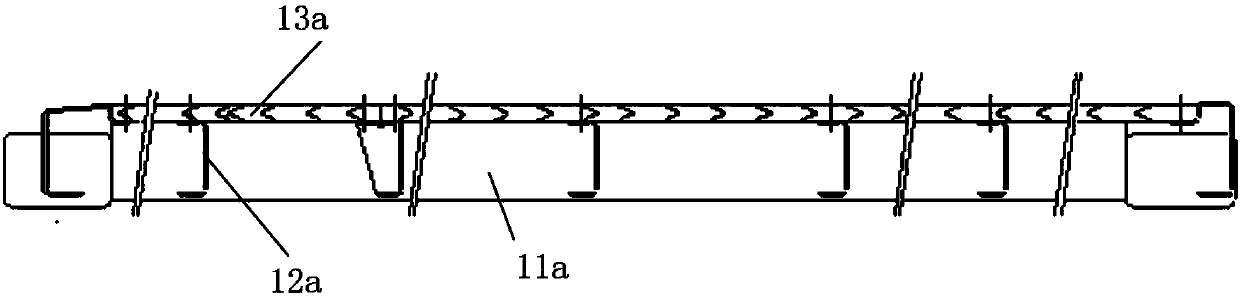

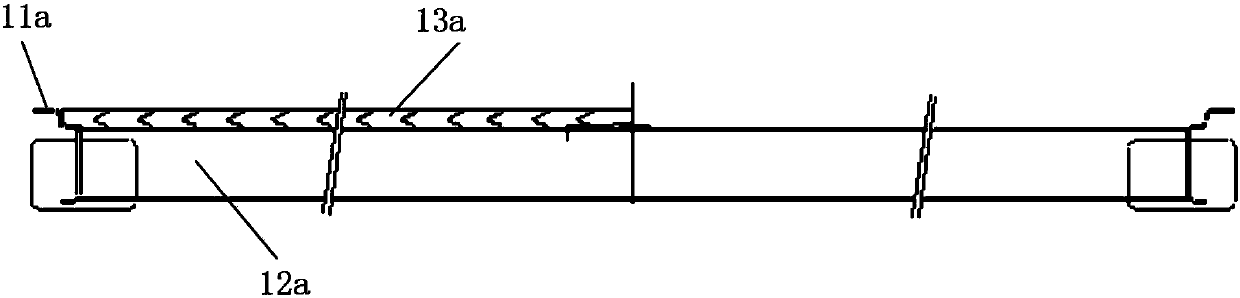

[0024] The present invention proposes a bottom side beam of a container. The bottom side beam is composed of a first bottom side beam part that can be connected with a side plate of a container and a second bottom side beam part that can be connected with a bottom cross beam of a container. The first bottom side beam part is overlapped with the second bottom side beam part.

[0025] The present invention proposes a container, which includes a bottom frame assembly and two side wall assemblies matched with the bottom frame assembly; wherein, the bottom frame assembly includes two second bottom side beams and several bottom cross beams; each side wall The component includes a first bottom side beam, and the two second bottom side beams of the underframe assembly are respectively superimposed and connected with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap