Self-reset viscoelastic energy dissipation steel beam

A viscoelastic, self-resetting technology, applied in beams, joists, trusses, etc., to avoid deformation and expansion problems, control residual deformation, and control repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

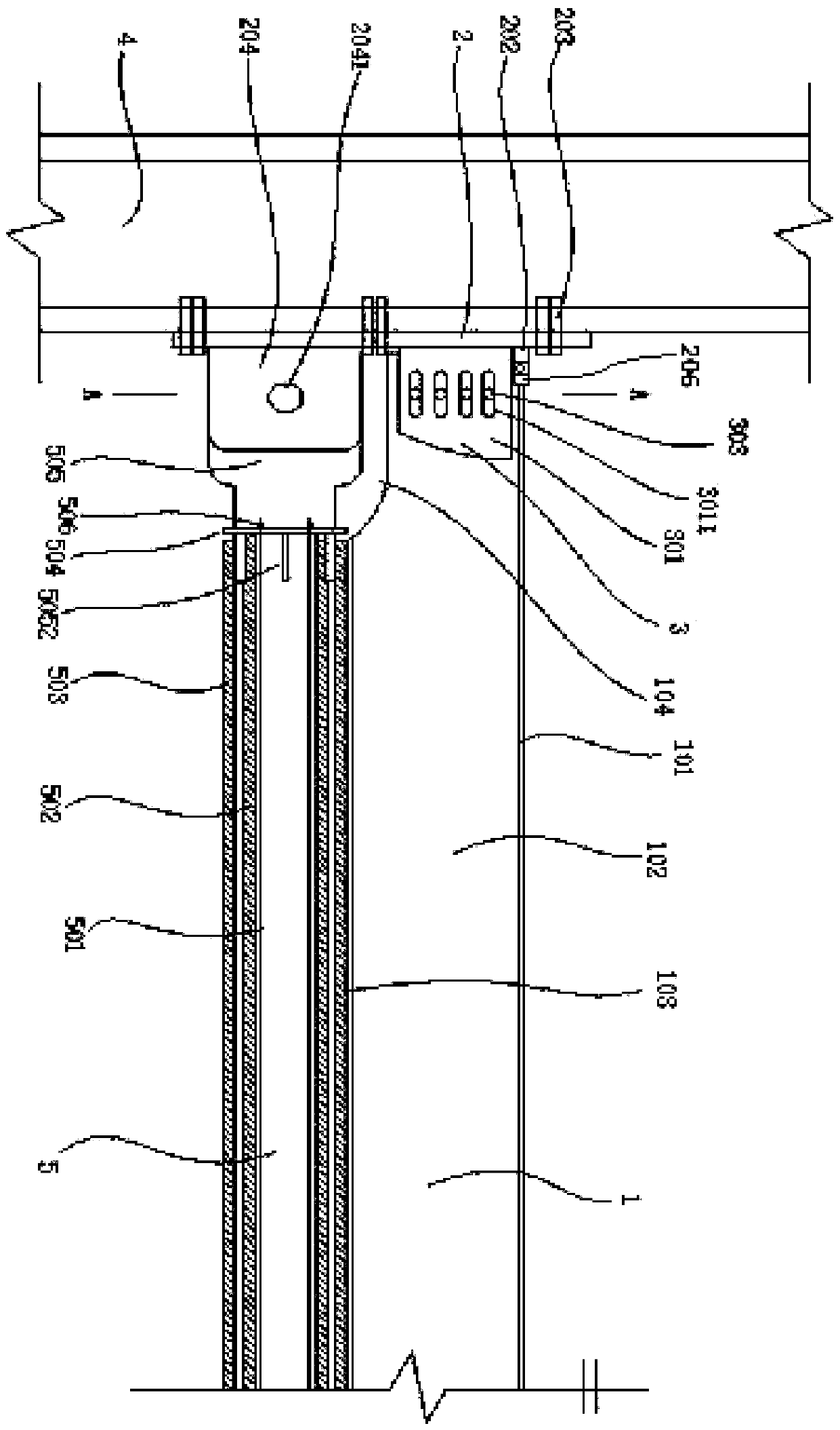

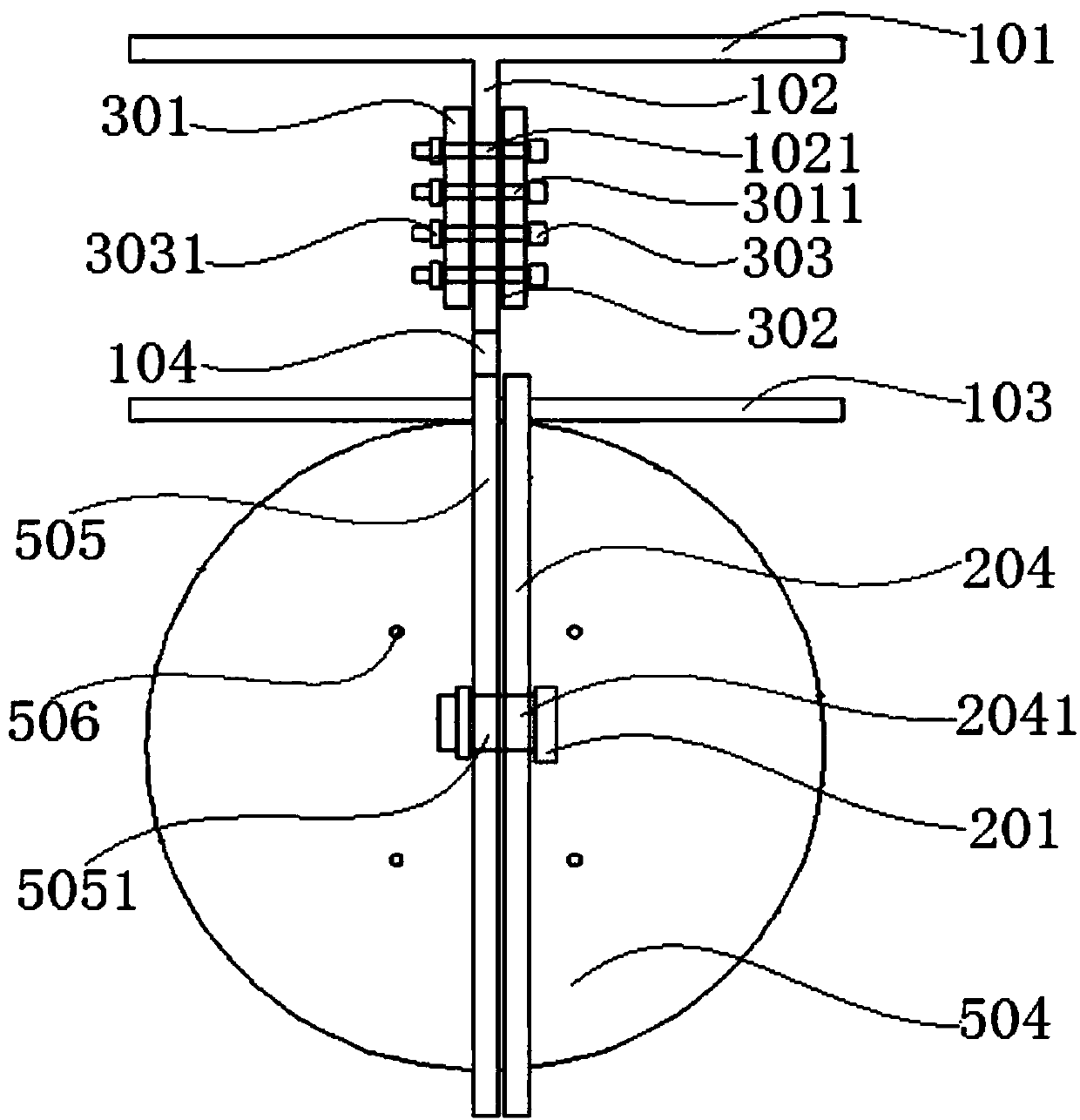

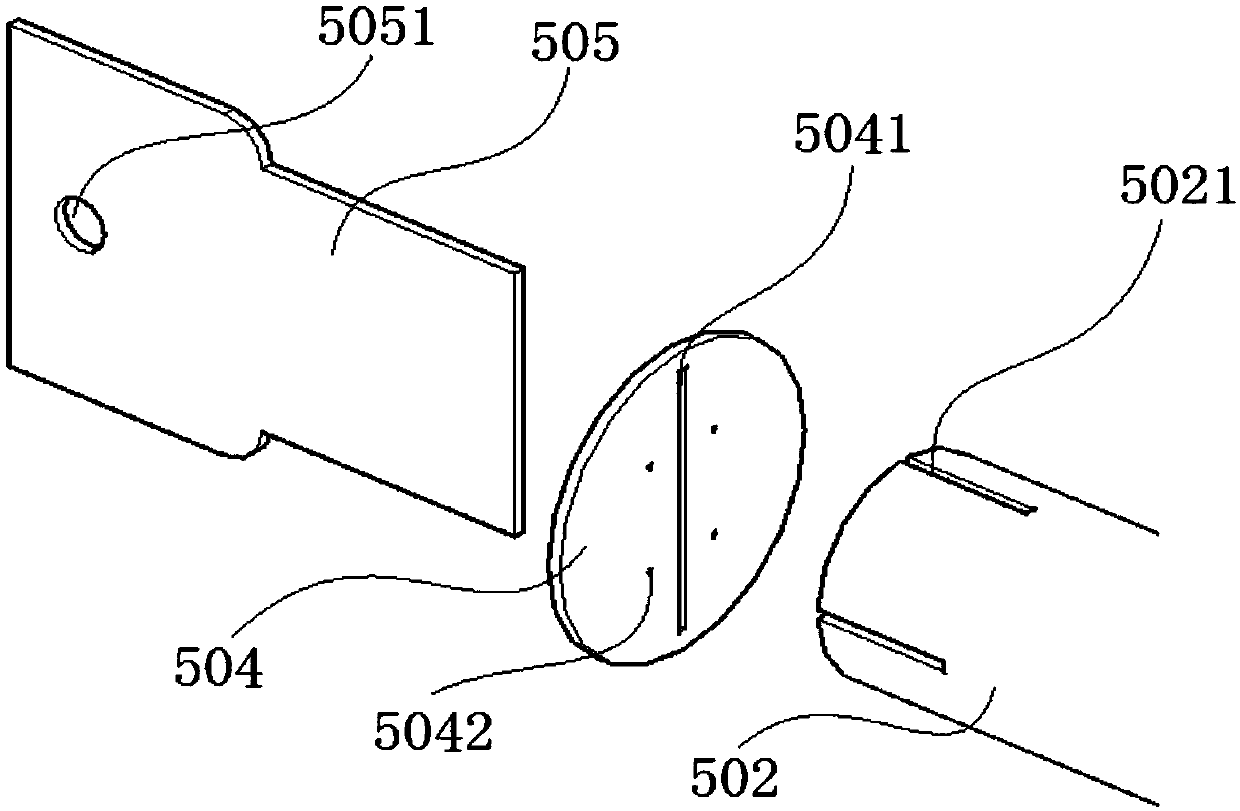

[0040] see figure 1 , self-resetting viscoelastic energy-dissipating steel beams, including I-shaped steel beams 1, beam-end connecting pads 2, viscoelastic energy-dissipating bodies 3, H-shaped steel frame columns 4 and self-resetting systems 5.

[0041]One side of the beam end connecting backing plate 2 is connected to the flange of the H-shaped steel frame column 4 through high-strength bolts 203 , and the other side is welded with connector I 202 and connector II 204 .

[0042] see figure 1 with figure 2 , the viscoelastic energy dissipating body 3 includes two shear connection plates 301 welded on the beam end connection backing plate 2 . A viscoelastic material 302 is attached to the inner side of the shear connection plate 301 . A number of slotted holes 3011 are opened on the shear connecting plate 301 .

[0043] The I-beam 1 has a groove 104 and a groove 105 . The groove 104 is formed by cutting off the lower flange of the end and the part of the end web near th...

Embodiment 2

[0051] The self-resetting viscoelastic energy-dissipating steel beam includes an I-shaped steel beam 1, a beam end connecting backing plate 2, a viscoelastic energy-dissipating body 3, an H-shaped steel frame column 4 and a self-resetting system 5.

[0052] One side of the beam end connecting backing plate 2 is connected to the flange of the H-shaped steel frame column 4 through high-strength bolts 203 , and the other side is welded with connector I 202 and connector II 204 .

[0053] The viscoelastic energy dissipating body 3 includes two shear connection plates 301 welded on the beam end connection backing plate 2 . A viscoelastic material 302 is attached to the inner side of the shear connection plate 301 . A number of slotted holes 3011 are opened on the shear connecting plate 301 .

[0054] The I-beam 1 has a groove 104 and a groove 105 . The groove 104 is formed by cutting off the lower flange of the end and the part of the end web near the lower flange. The groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com