Composite modifier for soil remediation of rare earth mining area and preparation method thereof

A technology for soil remediation and rare earth mining areas, applied in the direction of soil conditioning materials, chemical instruments and methods, applications, etc., can solve problems such as soil acidification, and achieve the effects of improving soil structure, improving soil fertility, good economic benefits and ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

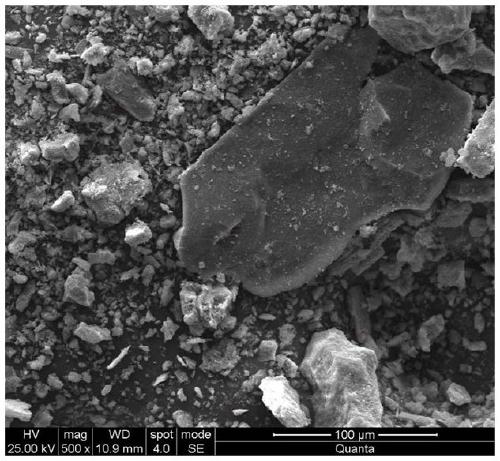

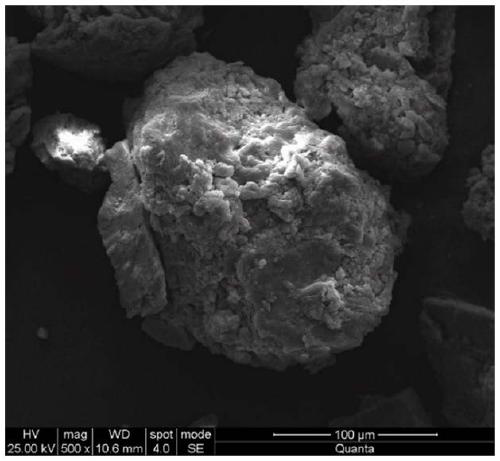

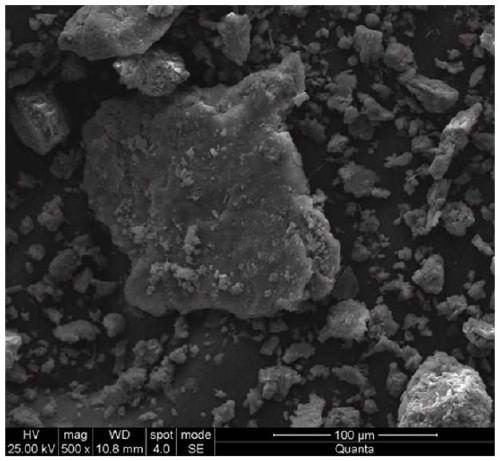

Image

Examples

Embodiment 1

[0037] Embodiment 1 provides a kind of compound improver that is used for the remediation of acidic sandy soil in ionic rare earth mining area, comprising the following components: in parts by weight, shell powder is 10 parts, crop waste is 10 parts, livestock and poultry manure is 20 parts, fermented sludge is 20 parts, bentonite is 15 parts, based on the total volume of shell powder, agricultural waste, livestock and poultry manure, fermented sludge and bentonite, plant adhesive is 100g / m 3 .

[0038] The preparation method of above-mentioned composite improver comprises the following steps:

[0039] 1) Mix 10 parts of crop waste, 20 parts of livestock manure, 20 parts of fermented sludge, and 15 parts of bentonite at room temperature;

[0040] 2) Put the mixed material obtained in step 1) into a blender, add 10 parts of shell powder, and stir evenly;

[0041] 3) Calculate and add 100g / m based on the volume of the mixture obtained in step 2) 3 Add water, adjust the humidi...

Embodiment 2

[0043] Embodiment 2 provides a kind of compound improver that is used for the remediation of acidic sandy soil in ionic rare earth mining area, comprising the following components: in parts by weight, shell powder is 15 parts, crop waste is 15 parts, livestock and poultry manure is 25 parts, fermented sludge is 25 parts, bentonite is 20 parts, based on the total volume of shell powder, agricultural waste, livestock and poultry manure, fermented sludge and bentonite, plant adhesive is 150g / m 3 .

[0044] The preparation method of above-mentioned composite improver comprises the following steps:

[0045] 1) 15 parts of crop waste, 25 parts of livestock and poultry manure, 25 parts of fermented sludge, and 20 parts of bentonite were uniformly mixed at room temperature;

[0046] 2) Put the mixed material obtained in step 1) into a blender, add 15 parts of shell powder, and stir evenly;

[0047] 3) Calculate and add 150g / m based on the volume of the mixture obtained in step 2) 3...

Embodiment 3

[0049] Embodiment 3 provides a kind of compound improver that is used for the remediation of acidic sandy soil in ionic rare earth mining areas, including the following components: in parts by weight, shell powder is 30 parts, crop waste is 20 parts, livestock and poultry manure is 30 parts, fermented sludge is 30 parts, bentonite is 35 parts, based on the total volume of shell powder, agricultural waste, livestock and poultry manure, fermented sludge and bentonite, plant adhesive is 200g / m 3 .

[0050] The preparation method of above-mentioned composite improver comprises the following steps:

[0051] 1) 20 parts of crop waste, 30 parts of livestock and poultry manure, 30 parts of fermented sludge, and 35 parts of bentonite are uniformly mixed at room temperature;

[0052] 2) Put the mixed material obtained in step 1) into a blender, add 30 parts of shell powder, and stir evenly;

[0053] 3) Calculate and add 200g / m based on the volume of the mixture obtained in step 2) 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com