Packaging structure of flip chip type filter

A packaging structure and flip-chip technology, which is applied in the field of filters, can solve the problems of unshielded chips and inflow of encapsulation glue, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

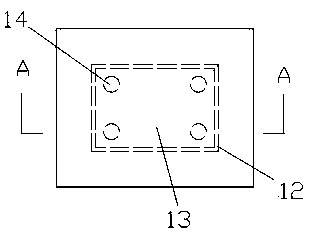

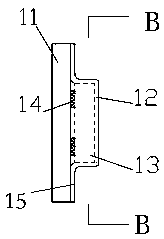

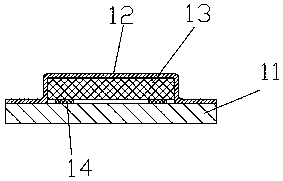

[0023] The present invention will be described in detail below with reference to the accompanying drawings.

[0024] Such as Figure 1-Figure 4 As shown, this embodiment provides a flip-chip 13-type filter packaging structure, including a substrate 11, a protective coating 12, a chip 13, and a connecting pin 14. The protective coating 12 has a plate-shaped body, and the center of the protective coating 12 13 Grooves with matching sizes, connecting portions 15 are formed around the grooves, and the chips 13 are keyed to the substrate 11 through the connecting pins 14, the protective coating 12 is fixed on the substrate 11 through the connecting portions 15, and the chip 13 is encapsulated in the grooves .

[0025] Specifically, in the packaging mechanism, the front surface of the substrate 11 is flat, the protective coating 12 is made of metal material, and the chip 13 is placed in the internal groove of the protective coating 12. After the protective coating 12 and the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com