Injector test device

A testing device and injector technology, which can be applied to fuel injection devices, measuring devices, pump testing, etc., can solve problems such as high cost and high wear, and achieve low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

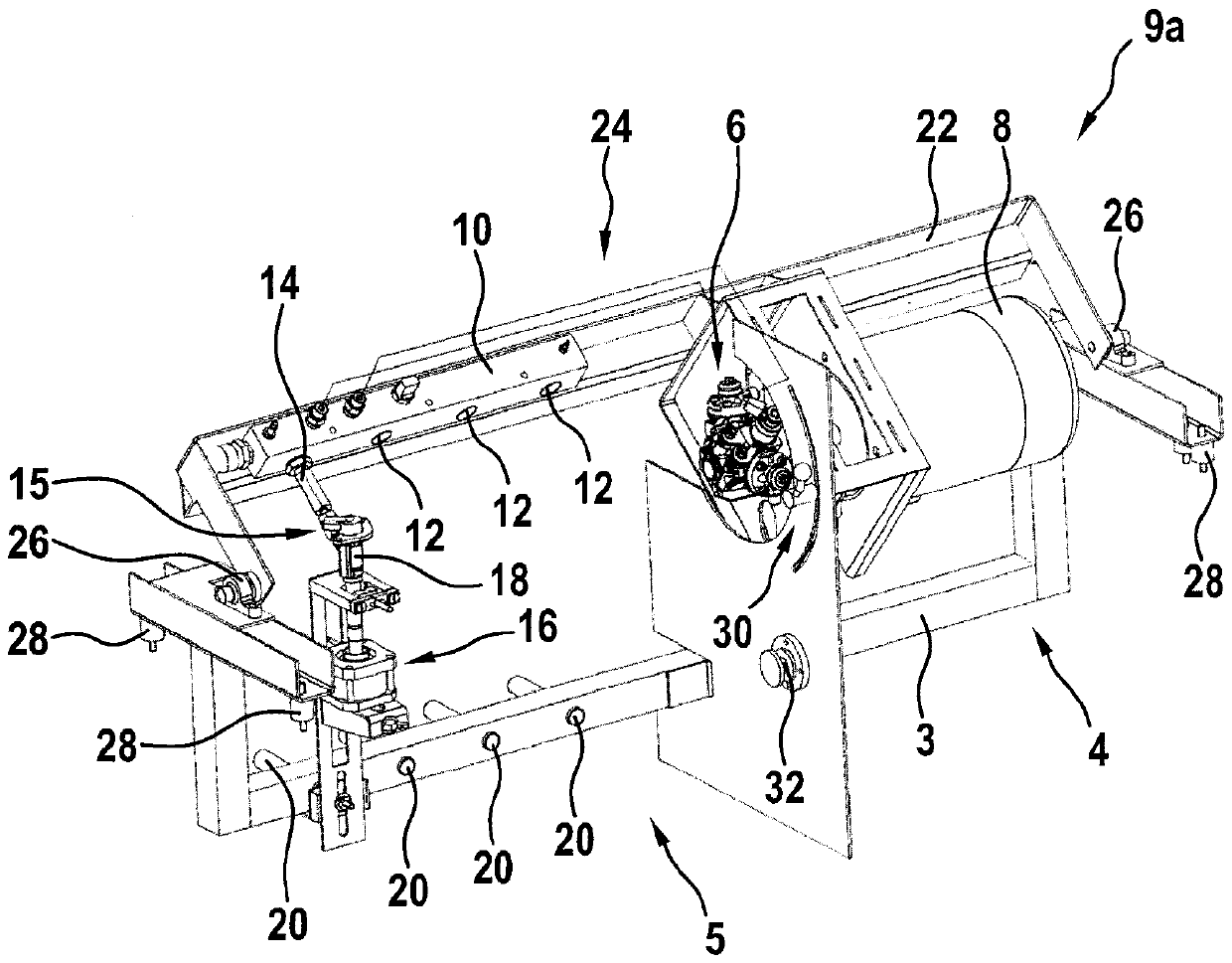

[0021] figure 1 A perspective front view of an injector test device 2 with a structural assembly 9a according to one embodiment of the invention is shown. Figure 2a and 2b A perspective view of a structural assembly 9 a comprising the functional elements of the injector testing device 2 is shown from two different angles.

[0022] The injector test device 2 includes the figure 1 , 2a The pressure generating area 4 shown on the right of and 2b and the test area 5 shown on the left respectively.

[0023] The injector testing device 2 has a carrier frame 3 which carries a fluid pump (high pressure pump) 6 and a motor 8 designed to drive the fluid pump 6 .

[0024] The pivotable frame 22 is supported on the carrier frame 3 via two pillow blocks 26 in such a way that the pivotable frame can pivot about a horizontal axis. This makes it possible to adjust the pivotable frame 22 about a horizontal axis from horizontal to vertical at any desired angle. The pivotable frame 22 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com