Gasket

A gasket and main body technology, applied in the field of gaskets, can solve the problems of increasing the number of parts, increasing the cost, and damaging the wall surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

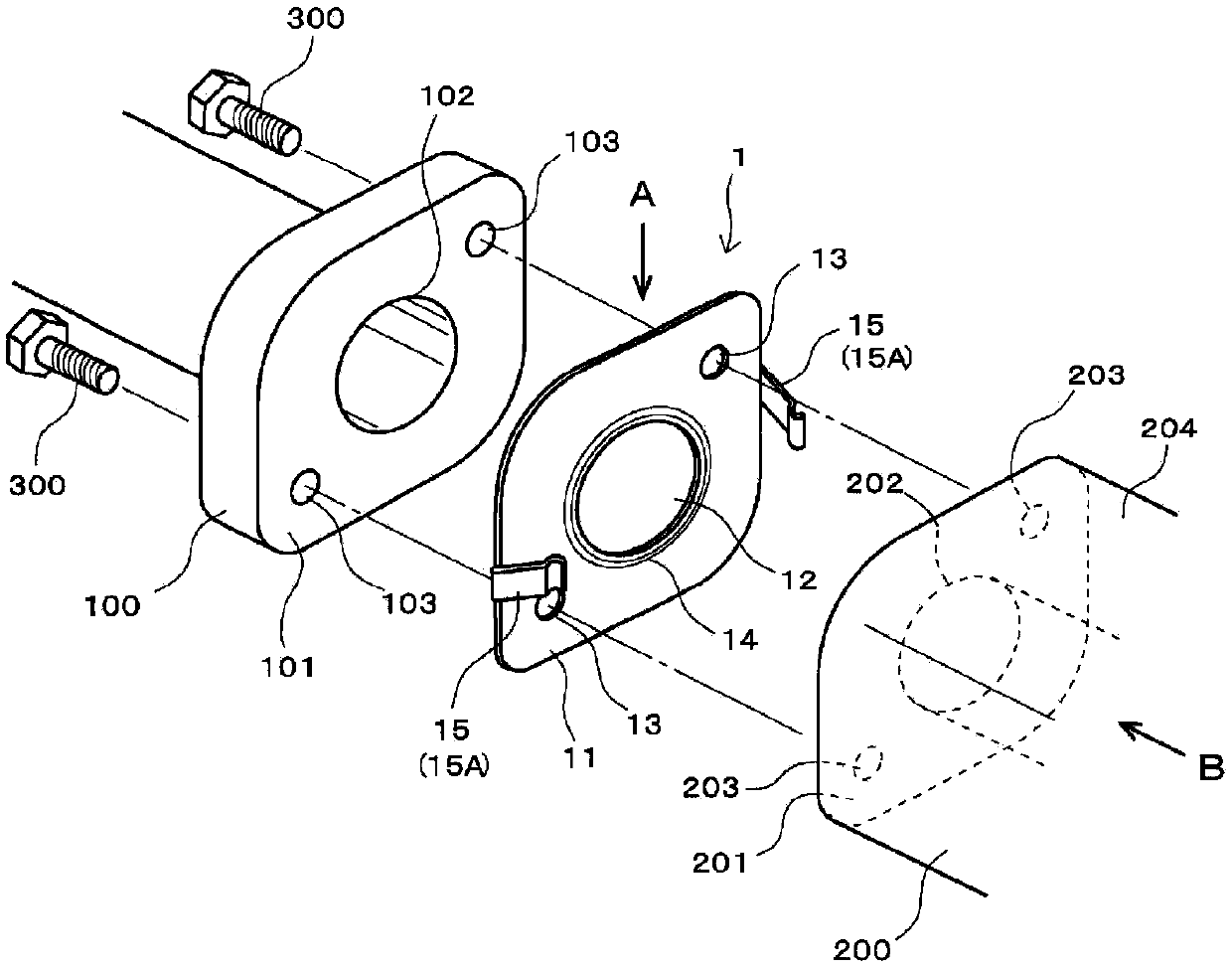

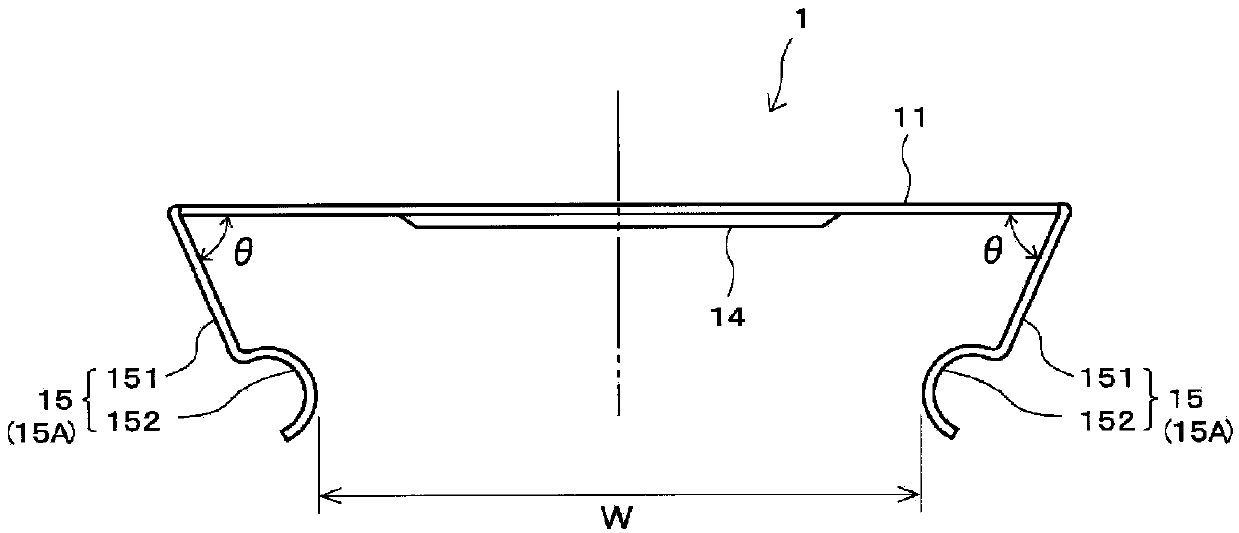

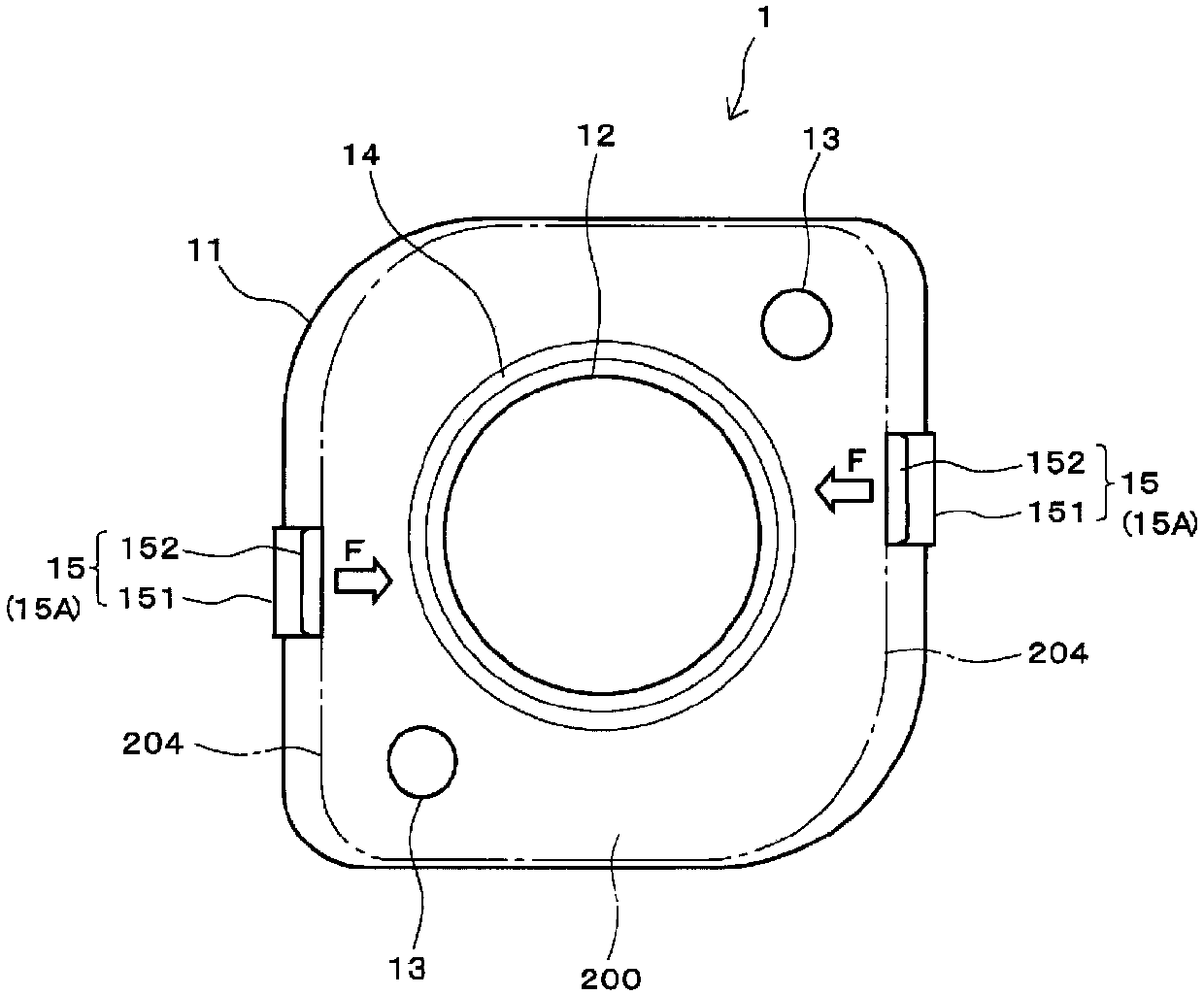

[0037] figure 1 It is an exploded perspective view showing the assembled state of the gasket according to the first embodiment of the present invention, figure 2 It is viewed from the direction of A figure 1 A side view of the gasket shown, image 3 From figure 1 B direction observation in figure 1 As shown in the diagram of the assembled state of the gasket, Figure 4 is description figure 1 The diagram showing the effect of the gasket, Figure 5 is description figure 1 A diagram showing an example of the assembly method of the spacer.

[0038] Such as figure 1 As shown, a gasket 1 is disposed between the opposing sealing surfaces 101 , 201 of a pair of components 100 , 200 . Openings 102 , 202 through which a fluid passes and bolt holes 103 , 203 are provided on the respective members 100 , 200 .

[0039] The gasket 1 is formed with an opening 12 and a bolt hole 13 on the gasket main body 11. The gasket main body 11 is made of metal substrates such as stainless st...

no. 2 approach

[0054] Figure 8 The gasket according to the second embodiment of the present invention is shown, (a) is a perspective view of the gasket, (b) is a figure 1 The figure in which the assembled state of the spacer shown in (a) is seen from the same direction as B direction. due to Figure 1 to Figure 7 Portions assigned the same reference numerals have the same structure, and therefore descriptions of these portions are referred to above, and are omitted here.

[0055] In this washer 2 , among the pair of locking claws 15 , 15 arranged to face each other across the opening 12 , one locking claw 15 forms an angle θ with the washer main body 11 of The first locking claw portion 15A is formed by bending toward the inside at an acute angle, and the other locking claw portion 15 is formed by bending at a right angle from the washer main body 11 . Hereinafter, in this specification, when referring only to the locking claw portion 15 bent and formed at the right angle, it is referred...

no. 3 approach

[0061] Figure 9 The gasket according to the third embodiment of the present invention is shown, (a) is a perspective view of the gasket, and (b) is a figure 1 The figure in which the assembled state of the spacer shown in (a) is seen from the same direction as B direction. due to Figure 1 to Figure 8 Portions assigned the same reference numerals have the same structure, and therefore descriptions of these portions are referred to above, and are omitted here.

[0062] The spacer 3 is in the Figure 1 ~ Figure 3 The shown washer 1 has a structure in which a pair of second locking claws 15B, 15B are added so as to face each other across the opening 12 . Such as Figure 9 As shown in (b), the first locking claws 15A, 15A and the second locking claws 15B, 15B are arranged at positions rotated by 90° around the opening 12 .

[0063] When the gasket 3 is assembled to the component 200, as in the case of the gasket 1, the gasket main body 11 can be self-held on the sealing surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com