Journal conversion clamping head for double-journal blades

A technology of turning chucks and journals, applied in the directions of clamping, clamping device, support, etc., can solve the problems of difficulty in adapting to mass production, poor consistency, and difficulty in meeting machining accuracy, so as to improve the pass rate of inspection, simple and convenient. The effect of clamping positioning and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

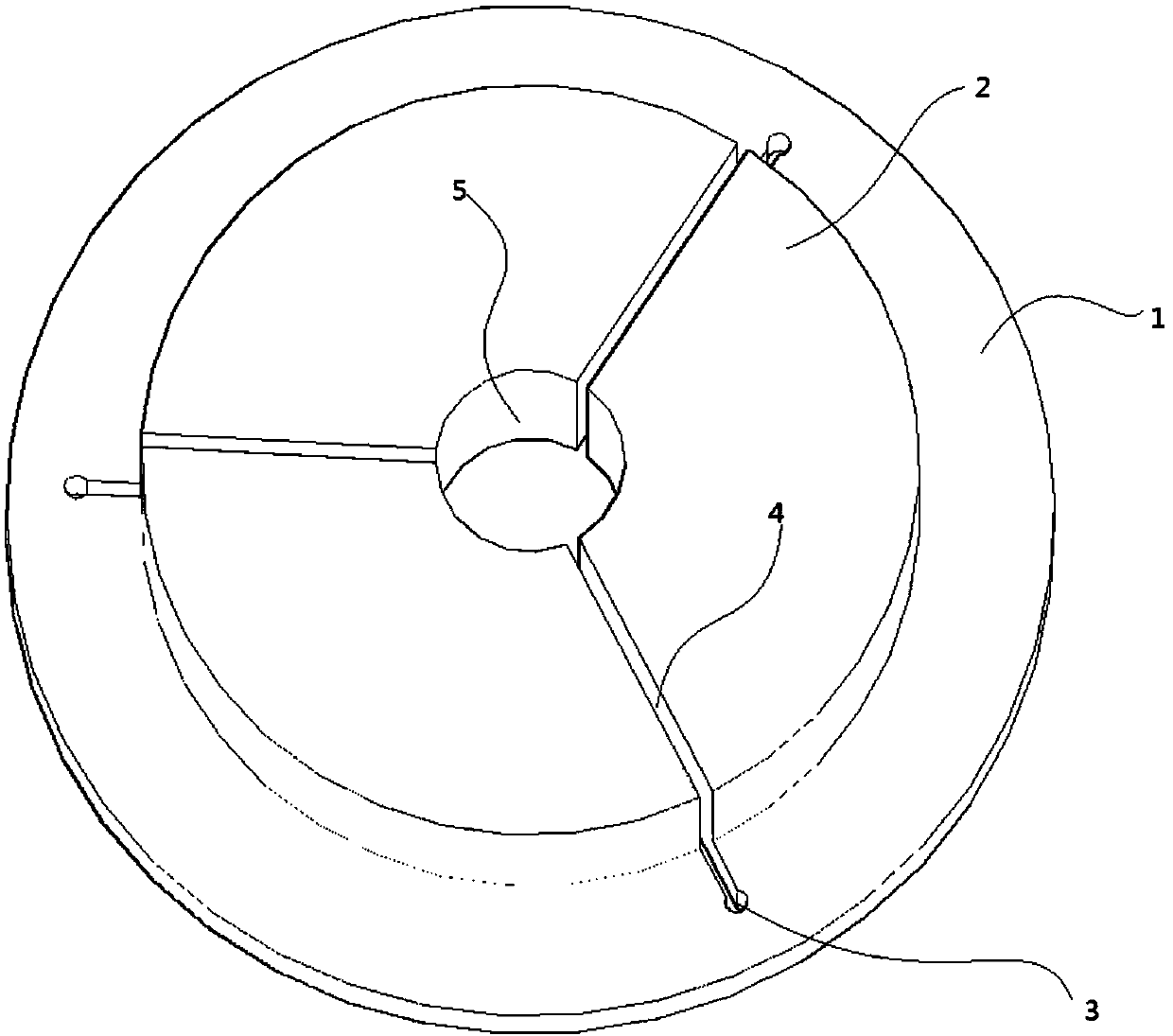

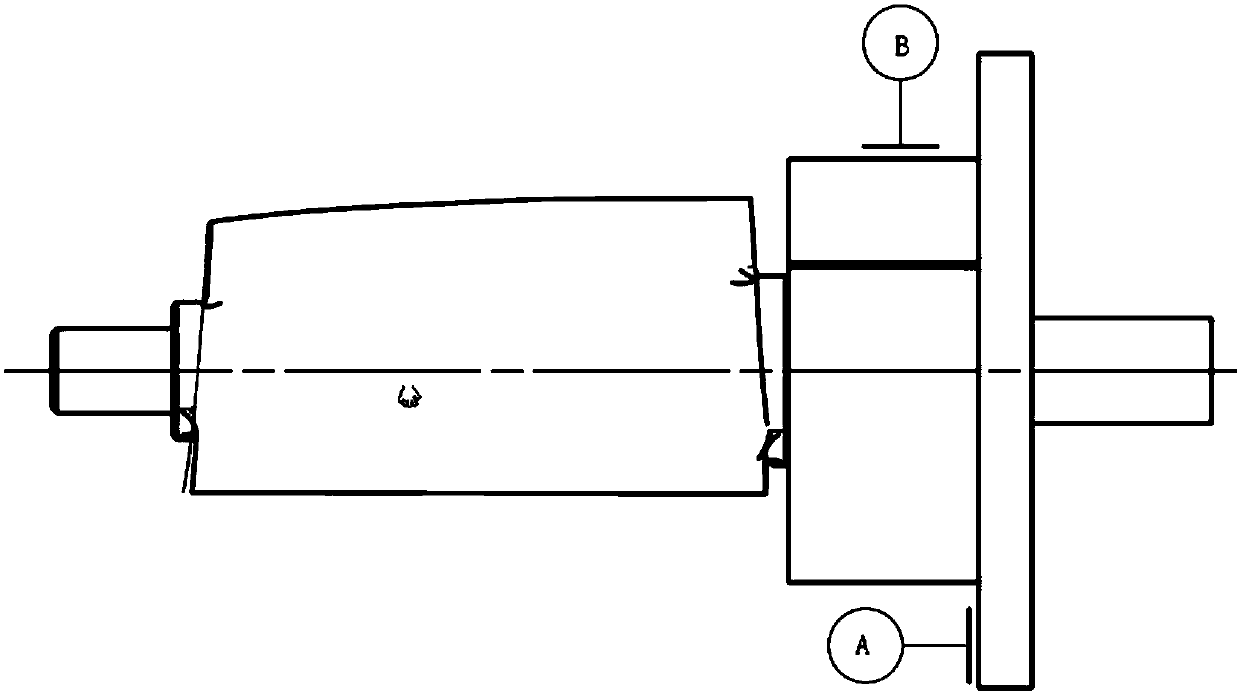

[0028] Example: Select journal blades as needed, and the conversion sleeve (the X-direction positioning surface is designed for the conversion sleeve, the size of the inner hole and the journal are in clearance fit, and the conversion sleeve has three 0.5mm gaps, such as: figure 2 ), three gripping chucks. The blade is installed in the conversion sleeve, the blade reference A is in contact with the X-direction positioning surface of the conversion sleeve, the positioning surface A of the conversion sleeve is in contact with the end face of the three-grip chuck, and the conversion sleeve is subjected to force when the three-grip chuck clamps the reference surface B of the conversion sleeve. Elastic deformation, the three gaps of the adapter sleeve become smaller, and the blade journal is clamped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com