Novel prestressed centralizer for centralizing ribs

A prestressing and centralizer technology, applied in drilling equipment, wellbore/well parts, earthwork drilling and production, etc., can solve problems affecting the quality of cementing sound amplitude, improve cementing quality, reduce manufacturing costs, and eliminate hollows Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

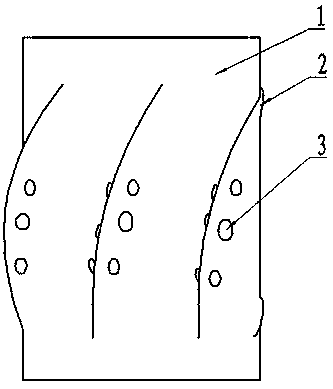

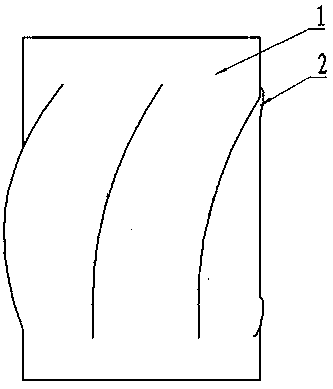

[0013] Such as figure 1 , 2 As shown, a new prestressed centralizer for centralizing ribs is characterized by a prestressed centralizer body 1, centralizing ribs 2, and a circular hole 3. On the prestressed centralizer body 1, five arc-shaped raised ribs 2 are equidistantly added, and three circular holes 3 with a diameter of 4 mm and a spacing of about 25 mm are punched on both sides of the arc-shaped raised ribs 2.

[0014] The working principle of a new type of prestressed centralizer with centralizing ribs of the present invention is: when the cementing slurry passes through the centralizing ribs 2 to generate a swirl effect to improve the cementing replacement efficiency, the cement slurry enters through the round hole 3 above the centralizing ribs 2 To the hollow between the centralizing rib 2 and the sleeve pipe, the inside of the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com