Strip shaped film anti-blocking agent and preparation method thereof

A technology of anti-blocking agent and film, which is applied in the field of strip-shaped film anti-aging agent and its preparation, can solve the problems of film anti-blocking agent performance, difficulty in stirring evenly, reducing anti-blocking agent, etc., and achieve excellent ultraviolet resistance and anti-aging functions, good Slippery effect, effect of improving tensile and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

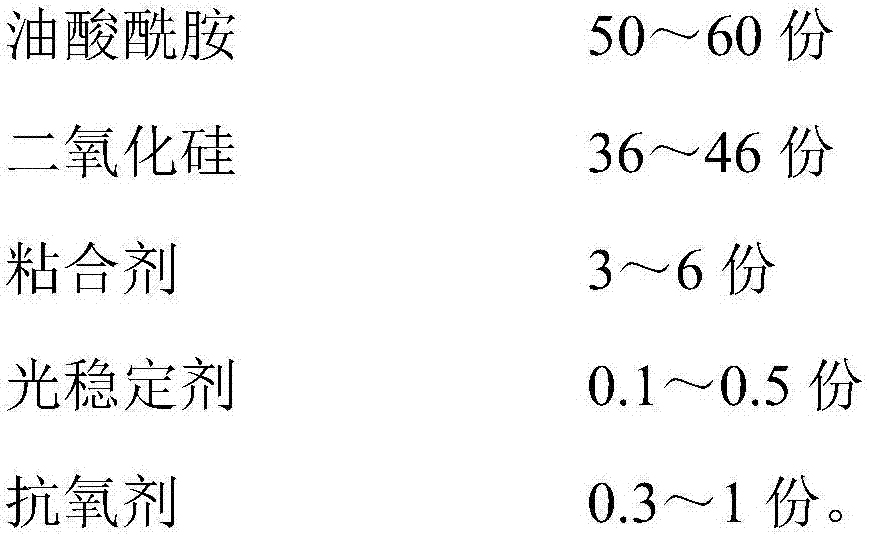

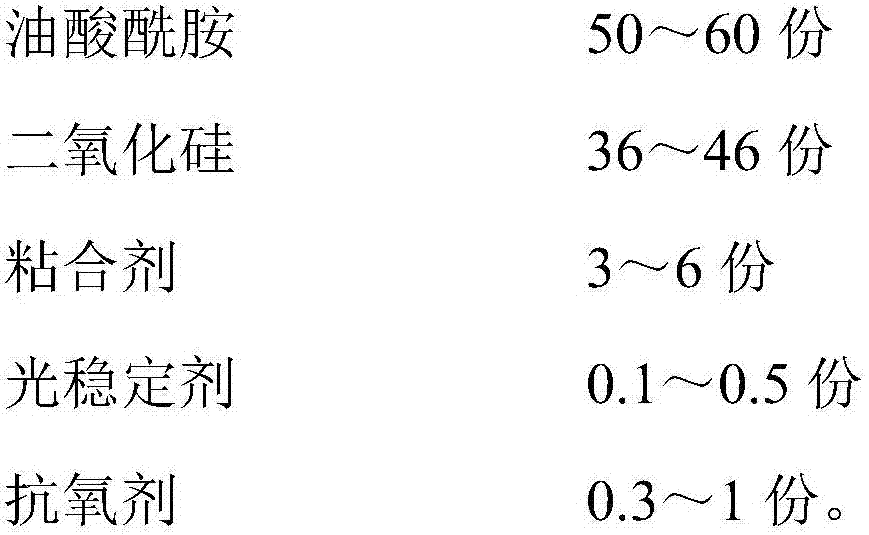

Embodiment 1-4

[0020] The preparation method of embodiment 1-4 is as follows:

[0021] Add oleic acid amide into the blender, then add silicon dioxide, light stabilizer and antioxidant, stir for 20 minutes and stir evenly, then use spray equipment to slowly spray the adhesive on the mixing material being stirred, about It takes 5 minutes, continue to stir for 20 minutes, then add the paired tooth granulator for cold granulation.

[0022] The products of Examples 1-4 were respectively blown by a film blowing machine at 188° C., the film thickness was 3 filaments, and the addition amount was 0.3%. Generally PE, PP film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com