A knowledge push method for heat treatment process based on material composition similarity

A technology of process knowledge and similarity, which is applied in the field of heat treatment process knowledge push based on material composition similarity, can solve the problems of not considering batch differences and insufficient targeted guidance ability, so as to improve retrieval efficiency, avoid manual operation, The effect of exact similarity matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] A method for pushing heat treatment process knowledge based on material composition similarity according to the present invention comprises the following steps:

[0142] (1) Enter the standard data of the chemical composition content of various metal materials related to heat treatment;

[0143] By establishing data master tables and sub-tables, enter the standard data of the chemical composition content of various metal material elements given in the national or industry testing standards, that is, enter the C, Si, P, S given in the national or industry testing standards Standard data of chemical composition content of other elements;

[0144] Set fields such as "material grade" and "test standard code" in the main table, and set attribute fields such as element number, element code, element content, and element weight in the sub-table;

[0145] Through the "element serial number" field, specify the sequence of elements, which is generally consistent with the sequence...

Embodiment 2

[0201] A method for pushing heat treatment process knowledge based on material composition similarity according to the present invention comprises the following steps:

[0202] (1) Enter the standard data on the chemical composition content of various metal materials related to heat treatment, and establish a data master table and sub-table;

[0203] (2) Accumulate and record the actual measurement data of the chemical composition content of each batch of metal materials, establish data master tables and sub-tables; accumulate and record the actual measurement of process parameters such as process methods, temperature, time, and vacuum degree during heat treatment of each batch of metal materials Data; accumulate and record the heat treatment performance and mechanical performance data of each batch of metal materials;

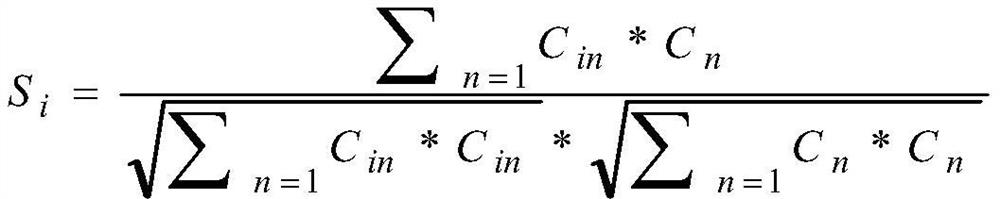

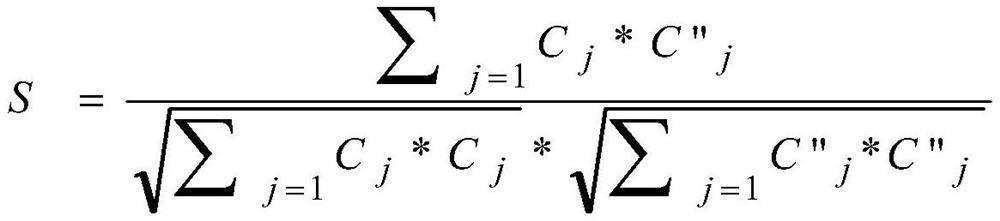

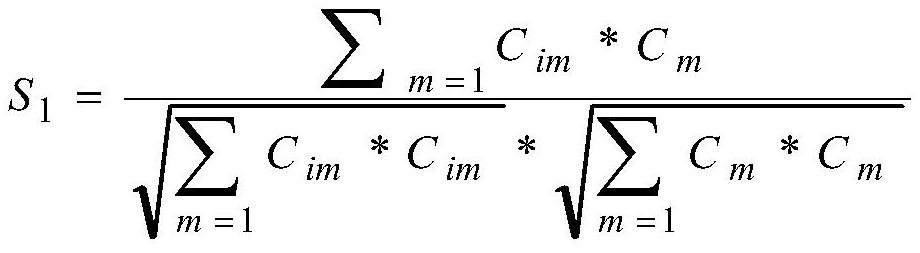

[0204] (3) Calculate the similarity index of each material according to the recorded measured data of the chemical composition content of each metal material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com